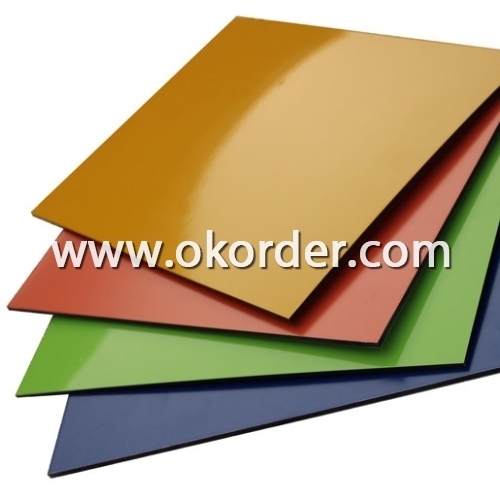

Aluminum Composite Panel 8XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Aluminium Composite Panel 8xxx

1.Coating: PVDF/PE

2.Core: unbreakable/ breakable LDPE core

3.ISO9001:2000 and SGS certificate

1. Standard:

according to GB/T 17748-1999 standard

2. Material:

a) Front: aluminum alloy sheet coated with fluoro-carbon resin

(PVDF) and polyester resin (PE) roasting painting

b) Core: nontoxic polyethylene.

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF and PE resin rolling roasting .

coating

e) Surface coating thickness: 30um

f ) Aluminum alloy sheet thickness: 0.1mm, 0.12mm, 0.15mm, 0.2mm,

0.3mm, 0.4mm, 0.45mm, 0.5mm

3. Dimensions:

a) Thickness: 3mm, 4mm

b) Width: 1220mm 1500mm..

c) Length: 2440mm, 3200mm, 4000mm,5000mm (max: 6 meter)

d) Weight: 5.5kg/sqm based on 4mm thickness.

e) Standard size: 1220 x 2440mm

f) Nonstandard sizes are available according to requirement of customers

4. Application scope of aluminium composite panel 8xxx:

1) Building exterior curtain walls..

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels..

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 40 days after getting the buyer's payment.

Repeat rolling - Cleaning - Pretreatment – Coating - Inspection - Film production - Plastic extruding – Compositing - Packing

- Q: Is it possible to utilize recycled aluminum for the production of cars or other types of vehicles?

- <p>Yes, recycled aluminum can be used to make cars and other vehicles. It is common practice in the automotive industry to use recycled aluminum in the manufacturing process due to its lightweight and strong properties. Recycled aluminum requires less energy to produce than new aluminum, making it more sustainable. It is used in various parts of vehicles, including engine components, body panels, and wheels. The use of recycled aluminum not only reduces waste but also contributes to energy savings and carbon emission reductions in vehicle production.</p>

- Q: What is the measure of aluminum's strength, specifically its yield strength and tensile strength?

- <p>Aluminum's strength is typically measured in terms of its yield strength and tensile strength. The yield strength of aluminum varies depending on the alloy and heat treatment, but it generally ranges from 10 to 45 MPa. Tensile strength, which is the maximum stress that aluminum can withstand before breaking, is typically between 90 to 600 MPa for different aluminum alloys. These values make aluminum a lightweight yet strong material suitable for various applications, including construction, automotive, and aerospace industries.</p>

- Q: This question asks about the methods used to determine the hardness of aluminum material.

- <p>The hardness of aluminum can be measured using various standardized tests. The most common methods include the Brinell Hardness Test, where a hard steel or carbide ball is pressed into the aluminum surface, and the Vickers Hardness Test, which uses a diamond pyramid indenter. The Rockwell Hardness Test is also used, applying a diamond cone or steel ball to the surface. The hardness is quantified by the depth of the indentation, and the results are expressed in specific hardness units like BHN (Brinell Hardness Number), HV (Vickers Hardness), or HR (Rockwell Hardness). These tests provide a measure of the material's resistance to deformation, which is crucial for applications requiring strength and durability.</p>

- Q: This question asks for examples of alloys that have a significant amount of aluminum and are known for their strength and ductility.

- <p>Alloys that are known for their high aluminum content and possess excellent strength and ductility include 6061 aluminum alloy, 7075 aluminum alloy, and 2024 aluminum alloy. 6061 is widely used in structural applications due to its balance of strength, corrosion resistance, and formability. 7075 is one of the strongest aluminum alloys and is used in aerospace and high-strength applications. 2024 is known for its good mechanical properties and is used in aircraft structures and other demanding applications. These alloys leverage the benefits of aluminum, such as low density and high resistance to corrosion, while their specific compositions and heat treatments enhance their strength and ductility.</p>

- Q: This question asks about the various applications of aluminum in construction materials.

- <p>Aluminum is widely used in building materials due to its lightweight, high strength, and resistance to corrosion. It is commonly used in window frames, door frames, curtain walls, and roofing systems for its durability and low maintenance requirements. Aluminum is also used in structural components such as beams and columns, and in the manufacturing of prefabricated buildings. Its malleability allows for the creation of various shapes and designs, making it ideal for both functional and aesthetic purposes in construction. Additionally, aluminum's thermal conductivity and reflectivity properties make it suitable for energy-efficient building envelopes.</p>

- Q: Is it possible to utilize recycled aluminum in the construction of buildings?

- <p>Yes, recycled aluminum can be used for building materials. It is commonly used in various construction applications due to its strength, durability, and lightweight properties. Recycled aluminum is not only environmentally friendly but also cost-effective compared to newly mined aluminum. It is used in the production of aluminum windows, doors, roofing materials, and structural components. Additionally, its recyclability reduces waste and conserves natural resources.</p>

- Q: Is it possible to utilize aluminum in the creation of innovative electronic devices?

- <p>Yes, aluminum can be used to make new types of electronic devices. Aluminum is a lightweight, corrosion-resistant, and highly conductive material, making it ideal for various electronic components. It's commonly used in heat sinks, casings, and wiring due to its thermal and electrical conductivity. Additionally, aluminum's malleability allows it to be shaped into intricate parts, which can be beneficial for compact and innovative designs in electronics. Furthermore, its abundance and low cost make it an attractive material for manufacturing new electronic devices.</p>

- Q: Is it possible to utilize recycled aluminum to manufacture new items?

- <p>Yes, recycled aluminum can be used to make new products. It is an environmentally friendly and cost-effective process. Recycling aluminum conserves energy, as it requires only 5% of the energy needed to produce new aluminum from raw materials. Recycled aluminum maintains its properties, making it suitable for various applications, including automotive parts, construction materials, and consumer goods. The process also reduces waste and greenhouse gas emissions, contributing to sustainability efforts.</p>

- Q: This question asks for an explanation of the process involved in the production of aluminum foil.

- <p>Aluminum foil is made through a process that starts with the extraction of aluminum from its ore, bauxite. The bauxite is refined to produce aluminum oxide, which is then reduced to aluminum using the Hall-H茅roult process. The aluminum is then melted and cast into large ingots. These ingots are heated and rolled into thin sheets using large industrial rolling mills. The aluminum is rolled multiple times, each pass reducing its thickness until it reaches the desired foil thickness. The final thin sheets are then cut and packaged as aluminum foil. This process requires precision and control to ensure the foil is uniform and free of defects.</p>

- Q: What specific rules or guidelines are there for incorporating aluminum in construction projects?

- <p>Yes, there are special regulations for using aluminum in construction projects. These regulations vary by country and region but generally include standards for material properties, structural integrity, fire resistance, and environmental impact. For instance, the American Society for Testing and Materials (ASTM) and the Aluminum Association provide guidelines for aluminum usage in construction. Compliance with building codes is crucial, and these codes often specify the grades of aluminum, allowable stress values, and methods of joining. Additionally, considerations for corrosion resistance, thermal expansion, and recycling potential are important. It's essential to consult local building codes and industry standards to ensure compliance when using aluminum in construction.</p>

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Composite Panel 8XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords