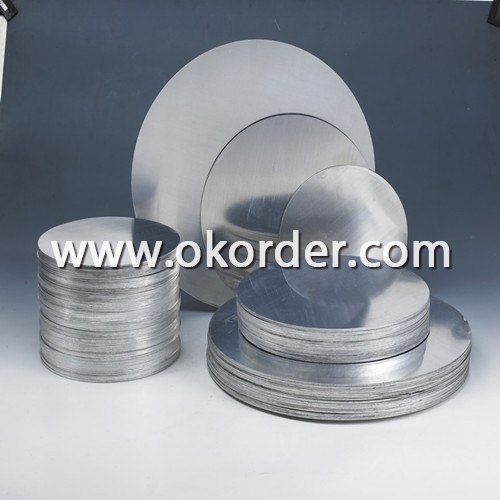

Aluminum Circle AA8XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of Aluminum Circle AA8XXX

Alloy | AA8XXX(AA8011, AA8006 etc.) |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.50mm--4.00mm |

Diameter: | 100mm- 1200mm |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

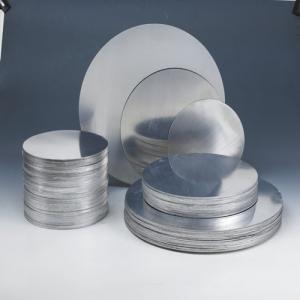

2 Usage/Applications of Aluminum Circle AA8XXX

Aluminum Circles have a wide variety of applications in cookware and kitchenware, including fried pans and pressure cooker. C.C. circle is excellent for spinning, deep-drawing (depth less than 10 cm), color or non-sticky painting with quite competitive price.

3 Packaging & Delivery of Aluminum Circle AA8XXX

Packaging:Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment:the goods will be delivered in 40 days after getting the buyer's payment.

4 Production Flow of Aluminum Circle AA8XXX

Melting-Rolling- Cutting- Annealing--Packing

- Q: This question asks about the impact of aluminum on human health.

- <p>Aluminum is a naturally occurring element that can be found in small amounts in various foods, water, and air. While it's not considered an essential nutrient, it's also not inherently harmful in small quantities. However, excessive exposure to aluminum has been linked to potential health concerns. Some studies suggest that high levels of aluminum might contribute to neurological disorders, particularly Alzheimer's disease, although the evidence is not conclusive. Aluminum can also cause digestive issues and bone disorders if ingested in large amounts. It's important to note that the human body does not absorb aluminum efficiently, and most ingested aluminum is excreted without issue. However, it's always advisable to minimize exposure to high levels of aluminum, especially for vulnerable populations such as infants and those with kidney issues.</p>

- Q: Explain the impact of adding magnesium to aluminum alloys on their characteristics.

- <p>Adding magnesium to aluminum alloys significantly enhances their strength, especially in the form of heat-treatable alloys known as Al-Mg or 5000 series alloys. Magnesium increases the alloy's resistance to corrosion, improves its formability, and raises its mechanical strength. These alloys are often used in applications requiring high strength-to-weight ratios, such as in the aerospace and automotive industries. The addition of magnesium also improves the alloy's weldability and resistance to stress corrosion cracking. However, it's important to note that excessive magnesium can lead to reduced ductility and increased susceptibility to stress corrosion cracking, so the amount added must be carefully controlled.</p>

- Q: This question asks for methods to enhance the ability of aluminum to resist corrosion.

- <p>To improve the corrosion resistance of aluminum, several methods can be employed: 1) Anodizing: This process creates a protective oxide layer on the aluminum surface, enhancing its resistance to corrosion. 2) Coating: Applying protective coatings such as paints or polymers can prevent direct contact with corrosive substances. 3) Alloying: Adding elements like magnesium or copper to aluminum can create alloys with better corrosion resistance. 4) Cathodic Protection: Using sacrificial anodes can protect aluminum from corrosion by diverting corrosion to the anode. 5) Proper Design: Designing structures to minimize water and dirt accumulation can reduce corrosion. 6) Regular Maintenance: Cleaning and inspecting aluminum components can help identify and address corrosion issues early.</p>

- Q: Is aluminum a suitable material for use in the electronics manufacturing industry?

- <p>Yes, aluminum is widely used in electronics manufacturing due to its excellent electrical conductivity, lightweight nature, and resistance to corrosion. It is commonly used in various electronic components such as heat sinks, capacitors, and wiring. Aluminum's malleability also allows it to be easily shaped into different forms, making it versatile for manufacturing purposes. Additionally, it is cost-effective and abundant, which further contributes to its popularity in the electronics industry.</p>

- Q: Is it safe and practical to use old aluminum cookware that has been stored for a long time?

- <p>Yes, you can reuse old aluminum cookware, but it's important to check its condition first. Look for any signs of damage, such as pits, scratches, or warping, as these can affect the cookware's performance and potentially release aluminum into your food. If the cookware is in good condition, clean it thoroughly and season it if necessary. Remember, aluminum cookware is not suitable for acidic foods or high heat, so use it accordingly to prolong its lifespan and maintain food safety.</p>

- Q: What is the chemical formula that represents aluminum?

- <p>The chemical formula for aluminum is Al. It is a lightweight, silvery-white metal that is found in the Earth's crust and is the most abundant metal there. Aluminum is a member of the boron group of chemical elements and is represented by the symbol Al, which is derived from the Latin word 'alumen', meaning alum.</p>

- Q: Is it possible to utilize aluminum in the manufacturing of tools and equipment?

- <p>Yes, aluminum can be used to make tools and equipment. It is valued for its lightweight, corrosion resistance, and high strength-to-weight ratio. Aluminum is commonly used in various applications such as aircraft manufacturing, automotive parts, and consumer electronics. It is also used in the construction of certain types of tools, particularly those that require lightness and durability without the need for extreme strength. However, for applications requiring high strength or resistance to high temperatures, other materials might be more suitable.</p>

- Q: Explain the economic and job market implications of using aluminum.

- <p>The use of aluminum has significant impacts on the economy and job market. It is a key material in various industries, including construction, automotive, aerospace, and consumer goods, which drives demand and economic growth. Aluminum production and processing create jobs directly in mining, refining, and manufacturing sectors, and indirectly in related services and supply chains. Additionally, its lightweight and corrosion-resistant properties make it valuable for energy-efficient transportation, contributing to environmental sustainability and opening new job opportunities in green technologies. However, it also presents challenges such as the need for energy-intensive production processes and the management of waste, which require innovative solutions and can lead to job creation in recycling and environmental management.</p>

- Q: Explain the interaction between aluminum and water, including any chemical reactions or properties.

- <p>Aluminum and water do not react directly under normal conditions. Aluminum is a reactive metal, but it is protected by a thin layer of aluminum oxide that forms on its surface when exposed to air, which prevents further reaction with water. This oxide layer is stable and acts as a barrier, making aluminum resistant to corrosion. However, in certain conditions, such as when aluminum is in contact with water and an electrolyte, it can lead to a process known as electrochemical corrosion. Additionally, aluminum can react with steam at high temperatures to form aluminum oxide and hydrogen gas.</p>

- Q: Is there a more environmentally friendly method for recycling aluminum?

- <p>Yes, aluminum can be recycled in a more environmentally friendly way. The process of recycling aluminum is already quite efficient, as it requires only 5% of the energy needed to produce new aluminum from raw materials. However, further improvements can be made by optimizing recycling processes, reducing transportation emissions, and increasing the use of recycled aluminum in new products. Additionally, implementing closed-loop recycling systems where aluminum is continuously recycled without loss in quality can minimize waste and environmental impact. Educating consumers about the importance of recycling and improving collection systems can also contribute to more sustainable aluminum recycling practices.</p>

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 1970 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Circle AA8XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords