Aluminum Composite Panel 6xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

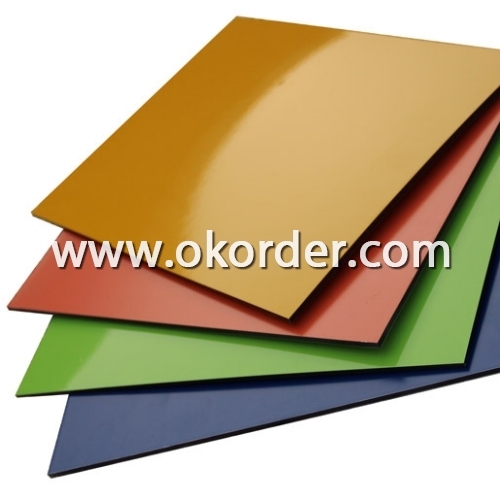

Specifications of Aluminium Composite Panel 6xxx

1.Coating: PVDF/PE

2.Core: unbreakable/ breakable LDPE core

3.ISO9001:2000 and SGS certificate

1. Standard:

according to GB/T 17748-1999 standard

2. Material:

a) Front: aluminum alloy sheet coated with fluoro-carbon resin

(PVDF) and polyester resin (PE) roasting painting

b) Core: nontoxic polyethylene.

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF and PE resin rolling roasting .

coating

e) Surface coating thickness: 30um

f ) Aluminum alloy sheet thickness: 0.1mm, 0.12mm, 0.15mm, 0.2mm,

0.3mm, 0.4mm, 0.45mm, 0.5mm

3. Dimensions:

a) Thickness: 3mm, 4mm

b) Width: 1220mm 1500mm..

c) Length: 2440mm, 3200mm, 4000mm,5000mm (max: 6 meter)

d) Weight: 5.5kg/sqm based on 4mm thickness.

e) Standard size: 1220 x 2440mm

f) Nonstandard sizes are available according to requirement of customers

4. Application scope of aluminium composite panel 6xxx:

1) Building exterior curtain walls..

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels..

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 40 days after getting the buyer's payment.

Repeat rolling - Cleaning - Pretreatment – Coating - Inspection - Film production - Plastic extruding – Compositing - Packing

- Q: This question asks for the common uses of aluminum in everyday life.

- <p>Aluminum is widely used in daily life due to its lightweight, corrosion resistance, and affordability. It's found in beverage cans, food packaging, and cookware. Aluminum is also used in construction for window frames, doors, and roofing. In transportation, it's utilized in the manufacturing of vehicles, aircraft, and ships due to its strength-to-weight ratio. Additionally, it's present in electronic devices, such as smartphones and laptops, for casings and heat sinks. Other applications include electrical wiring, sports equipment, and everyday items like foil and aluminum foil containers.</p>

- Q: This question asks for methods to determine the presence of aluminum in an alloy.

- <p>To determine if an alloy contains aluminum, one can use various analytical techniques. A common method is spectroscopy, which can identify the presence of specific elements by analyzing the wavelengths of light absorbed or emitted. Another approach is the use of a spark test, where a sample is struck against a grinding wheel to produce sparks; the color and pattern of these sparks can indicate the presence of aluminum. Chemical tests, such as the reaction with sodium hydroxide, can also be used, as aluminum reacts with NaOH to produce hydrogen gas. Lastly, X-ray fluorescence (XRF) is a non-destructive technique that can accurately determine the elemental composition of an alloy, including aluminum content.</p>

- Q: Describe the melting process of aluminum, including the temperature range and any specific characteristics.

- <p>The melting process of aluminum involves heating the metal to its melting point. Pure aluminum has a melting point of approximately 660.3掳C (1220.5掳F). During the melting process, aluminum changes from a solid to a liquid state. It is important to control the temperature carefully to avoid overheating, which can lead to oxidation and the formation of dross. Aluminum is a good conductor of heat, so it heats up quickly. The melting process is often carried out in a furnace or a crucible, and protective gases like chlorine or inert gases are used to prevent oxidation. The molten aluminum is then used for various applications such as casting or welding.</p>

- Q: This question asks about the potential dangers associated with exposure to aluminum through consumption of food and drinking water.

- <p>Aluminum exposure in food and water can pose several health risks. Chronic exposure may lead to cognitive dysfunction and Alzheimer's disease, although this link is still debated. It can also cause bone disease by leaching calcium, potentially leading to osteomalacia and osteoporosis. In the nervous system, aluminum can cause neurotoxicity, leading to symptoms like memory loss and impaired learning. Additionally, aluminum may accumulate in the brain, potentially contributing to neurodegenerative conditions. It's important to note that the extent of these risks can vary based on individual susceptibility and the level of exposure.</p>

- Q: Explain how the use of aluminum impacts energy consumption, including its production and recycling processes.

- <p>The use of aluminum has a significant impact on energy consumption, particularly in its production process. Aluminum is an energy-intensive material to produce, requiring large amounts of electricity to extract from its ore, bauxite, through a process called electrolysis. This process accounts for about 5% of global electricity consumption. However, aluminum is also highly recyclable, and recycling aluminum uses only 5% of the energy needed to produce it from raw materials. This makes aluminum recycling a more energy-efficient process, reducing the overall energy consumption related to aluminum use when recycling is prevalent.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum foil in the culinary process.

- <p>Aluminum foil offers several advantages in cooking, such as easy clean-up, even heat distribution, and the ability to create a seal for steaming or baking. It's also versatile, being suitable for both roasting and wrapping food for baking. However, there are disadvantages, including potential health concerns due to the leaching of aluminum into food, especially at high temperatures. Additionally, foil can tear easily, and it's not suitable for non-stick surfaces or use under broilers. Environmentally, it's not biodegradable and contributes to waste, which is a significant disadvantage.</p>

- Q: This question asks for innovative applications of recycled aluminum in various industries or everyday life.

- <p>Recycled aluminum is finding new uses in various sectors due to its sustainability and strength. It's being used in the automotive industry to make lighter vehicles, reducing fuel consumption and emissions. In construction, it's used for building materials like window frames and roofing, known for durability and energy efficiency. Recycled aluminum is also employed in the aerospace industry for aircraft parts due to its lightweight and high strength-to-weight ratio. Additionally, it's used in packaging, reducing waste and conserving resources. In electronics, recycled aluminum is used in the manufacturing of various components, contributing to the circular economy.</p>

- Q: What are the various applications of aluminum in the construction industry?

- <p>Aluminum is widely used in construction due to its lightweight, durability, and resistance to corrosion. It is utilized in the manufacturing of window frames, doors, roofing, and facades for its strength and low maintenance requirements. Aluminum is also used in structural components such as beams and columns, and in the construction of bridges and high-rise buildings. Its malleability allows for easy shaping and forming, making it ideal for intricate designs. Additionally, aluminum's thermal conductivity and reflectivity make it suitable for energy-efficient construction.</p>

- Q: Describe the process of manufacturing aluminum from its raw materials to the final product.

- <p>The manufacturing process of aluminum involves several key steps. Initially, bauxite ore, the primary source of aluminum, is mined. The ore is then crushed and washed to remove impurities. Next, the bauxite is processed through the Bayer process, which involves digestion in a caustic soda solution to produce a solution of sodium aluminate. This solution is then seeded with aluminum hydroxide, causing crystals to form, which are then filtered out, washed, and calcined to produce aluminum oxide, also known as alumina. Finally, in the Hall-H茅roult process, alumina is dissolved in a cryolite bath and electrolyzed to extract pure aluminum. This process involves passing an electric current through the bath, causing aluminum ions to be reduced and collected at the cathode as molten aluminum, which is then tapped off and cast into various forms for use in manufacturing.</p>

- Q: What are the various electronic components that utilize aluminum as a primary material?

- <p>Aluminum is used in several types of electronic components due to its good thermal conductivity, lightweight, and corrosion resistance. Some of the common components include: 1. Capacitors: Aluminum electrolytic capacitors are widely used for their high capacitance and low cost. 2. Heat sinks: Aluminum is a popular choice for heat sinks due to its ability to dissipate heat efficiently. 3. Semiconductors: Aluminum is used in semiconductor manufacturing, particularly for interconnects and as a barrier layer. 4. Conductive adhesives: Aluminum-filled adhesives are used for bonding components in electronics. 5. Wires and cables: Aluminum wire is used in some applications due to its lower weight compared to copper. 6. Reflectors: Aluminum is used in light reflectors for its reflective properties. 7. Housings and enclosures: Aluminum is used in the construction of electronic device casings for its strength and lightweight properties.</p>

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Composite Panel 6xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords