Aluminum Coil Ontario - Wooden Coated Good Quality 1060 3003 3105

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

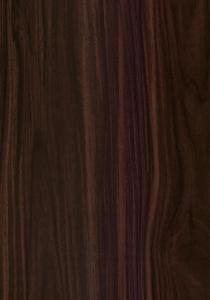

Structure of Aluminum Coil Wooden Coated Good quality 1060 3003 3105 Description:

Aluminum Coil Wooden Coated Good quality 1060 3003 3105are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.The Aluminum Coil Wooden Coated Good quality 1060 3003 3105 have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminum Coil Wooden Coated Good quality 1060 3003 3105:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminum Coil Wooden Coated Good quality 1060 3003 3105:

Aluminum Coil Wooden Coated Good quality 1060 3003 3105 Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the different alloy grades used in aluminum coils?

- There are several different alloy grades used in aluminum coils, each with their own unique properties and applications. Some of the most commonly used alloy grades include: 1. 1100: This is a commercially pure aluminum grade, known for its excellent corrosion resistance and high thermal conductivity. It is often used in applications that require good formability, such as fin stock, heat exchangers, and chemical equipment. 2. 3003: This alloy grade is known for its moderate strength and good workability. It is commonly used in applications that require both corrosion resistance and formability, such as packaging, cooking utensils, and general sheet metal work. 3. 5052: This alloy grade offers a good combination of strength, formability, and corrosion resistance. It is often used in marine environments, as well as in transportation equipment, such as fuel tanks and vehicle bodies. 4. 6061: This is a heat-treatable alloy grade, known for its excellent strength and weldability. It is commonly used in structural applications, such as bridges, aircraft parts, and bicycle frames. 5. 7075: This is another heat-treatable alloy grade, known for its high strength-to-weight ratio. It is often used in aerospace applications, as well as in the manufacturing of high-stress components, such as firearm parts and rock climbing equipment. These are just a few examples of the different alloy grades used in aluminum coils. The selection of the appropriate grade depends on the specific requirements of the application, such as desired strength, corrosion resistance, formability, and thermal conductivity.

- Q: Are aluminum coils resistant to abrasion?

- Yes, aluminum coils are generally resistant to abrasion. Aluminum is known for its durability and ability to withstand wear and tear. It has a high strength-to-weight ratio and excellent corrosion resistance properties, making it suitable for various applications where abrasion resistance is required. Additionally, aluminum coils are often coated or treated with protective finishes, further enhancing their resistance to abrasion. However, the specific level of resistance may vary depending on the specific alloy and the surface treatment applied to the coils.

- Q: What is the typical tensile strength of aluminum coils?

- The typical tensile strength of aluminum coils can vary depending on the specific grade and temper of the aluminum. However, a commonly used grade, such as 3003, typically has a tensile strength of around 20,000-30,000 pounds per square inch (psi).

- Q: How do aluminum coils compare to titanium coils in terms of weight?

- Aluminum coils are significantly lighter in weight compared to titanium coils. Aluminum has a lower density than titanium, which means that the same volume of aluminum weighs less than titanium. This characteristic makes aluminum coils a preferred choice in various industries where weight reduction is crucial, such as aerospace and automotive applications. Titanium coils, on the other hand, are known for their exceptional strength and high corrosion resistance, making them suitable for environments where durability is a priority. Ultimately, the choice between aluminum and titanium coils depends on the specific requirements and trade-offs desired for a particular application.

- Q: Are aluminum coils suitable for electrical insulation applications?

- Aluminum coils, unfortunately, do not meet the requirements for electrical insulation applications. This material possesses a high conductivity, enabling the passage of electricity. To ensure safety and prevent short circuits or electrical shocks, insulation is essential in electrical applications. Consequently, materials like plastics, rubber, or fiberglass, which exhibit low electrical conductivity, are commonly employed for electrical insulation purposes.

- Q: How do aluminum coils contribute to the insulation properties of products?

- The insulation properties of various products are greatly enhanced by aluminum coils, playing a crucial role. The utilization of aluminum coils in insulation systems leads to improved thermal efficiency, decreased heat transfer, and reduced energy consumption. To begin with, aluminum possesses excellent heat and electricity conducting abilities. This particular characteristic enables aluminum coils to distribute and dissipate heat effectively, preventing the transfer of thermal energy from one side of the product to the other. Consequently, aluminum coils act as a barrier, minimizing the loss or gain of heat, which is essential for maintaining optimal temperatures across different applications. Additionally, aluminum coils exhibit low thermal conductivity. This implies that they are not easily affected by temperature changes and do not efficiently transfer heat. As a result, products incorporating aluminum coils can better withstand external temperature fluctuations, providing superior insulation against hot or cold conditions. Moreover, aluminum coils are lightweight, allowing for easy handling and installation in various products. This lightweight attribute is advantageous as it does not impose significant weight on the overall structure, making it suitable for industries requiring portable or lightweight insulation solutions. Furthermore, aluminum possesses high resistance to corrosion, making it ideal for applications in humid or corrosive environments. This durability ensures that the insulation properties of products containing aluminum coils remain effective over an extended period, without deterioration or compromise in performance. Additionally, aluminum is a recyclable material, aligning with sustainable practices. The use of aluminum coils in insulation products promotes environmental consciousness by reducing waste and energy consumption associated with the manufacturing of new materials. In conclusion, aluminum coils contribute significantly to the insulation properties of products by effectively distributing and dissipating heat, minimizing heat transfer, and resisting temperature fluctuations. Their lightweight nature, durability, and recyclability further augment their effectiveness as an insulation component. Overall, aluminum coils represent a valuable addition to insulation systems, enhancing thermal efficiency and decreasing energy consumption.

- Q: What are the different thickness tolerances for aluminum coils?

- The different thickness tolerances for aluminum coils can vary depending on the specific application and industry standards. However, common thickness tolerances for aluminum coils range from +/- 0.002 inches to +/- 0.010 inches, ensuring precision and consistency in the manufacturing process.

- Q: Can aluminum coils be used for structural purposes?

- No, aluminum coils are typically not used for structural purposes as they lack the necessary strength and rigidity required for structural applications.

- Q: Is it possible to utilize aluminum coils in the packaging of food products?

- <p>Yes, aluminum coils can be used for food packaging. They are commonly used in the production of aluminum foil, which is a popular material for food packaging due to its properties such as light weight, barrier to light and oxygen, and recyclability. Aluminum foil is used to wrap food, line baking sheets, and create containers, providing a protective barrier that helps to preserve freshness and extend shelf life. However, it's important to ensure that the aluminum used meets food-grade standards to avoid any health risks.</p>

- Q: i am thnking of building my own aluminum john boat and using the propulsion from a jetski to power it, i was wondering if anyone had taken on a project like this and had a few pieces of advice to offer while i am still in the planning stages. the biggest concern i have right now involves the tunnel for the intake, should i use the original fiberglass from the jetski or build up a tunnel out of aluminum for it?

- While I have not built a john boat of aluminum, I have built or fabricated a lot of other things. If this were my project, and as it is the scoop you are talking about, not the tunnel itself. Aluminum is one of the most expansive metals, and I do not see you being able to seal a fiberglass/aluminum interface with much promise of it holding long term. I would fabricate or mold a new one of aluminum so it would have the same expansion rate as the metal around it. Electrolysis is not an issue, but I think the thermal expansion difference would be on the seals. good luck on your project, sounds fun.

Send your message to us

Aluminum Coil Ontario - Wooden Coated Good Quality 1060 3003 3105

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords