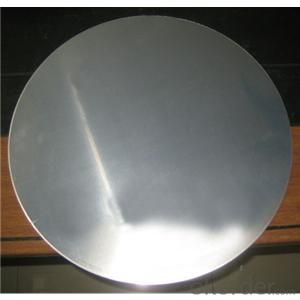

Aluminum 18 Gauge Flat Circle 1070/1060/1050 for Spinning, Pressing, Deep Drawing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Specifications of Aluminium Circles :

Aluminium circle

1.Bright surface, no scratch

2.Deep drawing

3.Customized packing ways are welcomed

4.High quality

Aluminium Circles :

1) Alloy: 1050, 1060, 1070, 1100, 1200, 3003, 3004, 3105 , 5005, 5052, 6061, 8011

2) Temper: O, H12, H14, H16, H18, H22, H24, H26, H32

3) Thickness: 0.30-4.00mm

4) Diameter: 100-980mm

5) Dimensions can be produced according to clients' specifications

6) Good plasticity, conductivity

7) Generally used in industrial and construction applications

l Packaging & Delivery

Packaging detail: Seaworthy Export Standard Wooden Pallet

Delivery detail: About 25 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

The business scope of CNBM covers from manufacturing and sales of a series of building materials to scientific research and design, import and export trade. In many of these fields, CNBM is playing the leading role.

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Name:Amanda

Email:amandaqian@okorder.com

- Q: What are the safety standards for aluminum products used in everyday life?

- <p>Yes, there are safety standards for using aluminum products in daily life. These standards ensure the safety and quality of aluminum products. They cover aspects such as material composition, manufacturing processes, and product performance. The standards vary by country and product type, but they generally aim to prevent health risks associated with aluminum exposure, such as toxicity and contamination. Compliance with these standards is crucial to protect consumers and ensure the longevity and reliability of aluminum products.</p>

- Q: What other applications can aluminum be utilized for in the manufacturing industry besides common uses?

- <p>Aluminum has a wide range of alternative uses in manufacturing due to its lightweight, corrosion resistance, and strength. It is used in the automotive industry for car parts to reduce weight and improve fuel efficiency. In aerospace, aluminum is crucial for aircraft construction due to its strength-to-weight ratio. It's also used in the construction of buildings for window frames, roofing, and facades. In the packaging industry, aluminum is used for food and beverage cans, as well as pharmaceutical blister packs. Additionally, aluminum is utilized in electrical components like wiring and transformers due to its excellent conductivity. It's also found in various consumer goods, such as bicycles, sports equipment, and electronic devices.</p>

- Q: Is it possible to utilize aluminum to enhance the durability and efficiency of batteries?

- <p>Yes, aluminum can be used to make batteries more durable and efficient. Aluminum's lightweight, high conductivity, and corrosion resistance make it a favorable material for battery components. In particular, aluminum-air batteries leverage aluminum's ability to provide a high energy density. Additionally, research is ongoing to improve lithium-ion batteries by using aluminum as a component in the anode, which can potentially increase energy storage capacity and lifespan. However, challenges such as aluminum's reactivity and the development of efficient recycling methods must be addressed for widespread adoption in battery technology.</p>

- Q: This question asks for common applications of aluminum in everyday life.

- <p>Aluminum is widely used in daily life due to its lightweight, durability, and resistance to corrosion. It is commonly found in beverage cans, food packaging, and cookware. Aluminum is also used in construction for window frames, doors, and roofing. It is a key material in the manufacturing of vehicles, including cars, airplanes, and bicycles, due to its strength-to-weight ratio. In electronics, aluminum is used in heat sinks and wiring. Additionally, it is used in everyday items like foil, furniture, and sports equipment. Its versatility makes aluminum an essential material in many aspects of modern life.</p>

- Q: Is aluminum suitable for use in paint and coating applications?

- <p>Yes, aluminum can be used in paints and coatings. It is often used in the form of aluminum pigments or flakes, which provide a metallic appearance and enhance the durability and corrosion resistance of the coating. Aluminum pigments are also valued for their ability to reflect light and heat, making them useful in applications requiring thermal insulation or reflective properties. Additionally, aluminum can be used in powder coatings, providing a hard, wear-resistant finish.</p>

- Q: This question asks for a list of negative aspects or drawbacks associated with the use of aluminum.

- <p>Aluminum, while widely used, has several disadvantages. It is non-magnetic and non-conductive, which limits its use in certain applications requiring these properties. Aluminum is also relatively soft and can dent or scratch easily, affecting its durability in some contexts. Additionally, its production process is energy-intensive and contributes to environmental pollution. Furthermore, aluminum can have negative health impacts if ingested in large quantities, potentially leading to neurological disorders. Lastly, aluminum's light weight can be a disadvantage in applications where greater strength or weight is required.</p>

- Q: Can aluminum be recycled repeatedly without losing its quality or strength?

- <p>Yes, aluminum can be recycled multiple times without significant degradation in quality or strength. The recycling process retains most of its original properties, making it one of the most sustainable materials. Each recycling cycle does not diminish its performance, unlike some other materials. This characteristic makes aluminum a valuable resource in reducing waste and conserving energy.</p>

- Q: This question asks for examples of how recycled aluminum can be utilized.

- <p>Recycled aluminum has numerous applications, including the manufacturing of beverage cans, automotive parts, construction materials, and electronic components. It is also used in the production of aluminum foil, packaging materials, and various household items. Recycled aluminum is valued for its durability, lightweight properties, and energy efficiency in production, making it an environmentally friendly choice for many industries.</p>

- Q: Is aluminum a suitable material for use in space exploration?

- <p>Yes, aluminum is indeed used in space exploration. It is valued for its lightweight properties, which are crucial for reducing the mass of spacecraft and payloads. Additionally, aluminum has good thermal conductivity and can withstand extreme temperature variations, making it suitable for various components in spacecraft. It is also resistant to corrosion and has high reflectivity, which can be beneficial for heat management and communication systems. However, its low strength-to-weight ratio compared to some other materials like titanium or advanced composites means it is often used in combination with other materials or for specific applications where its properties are advantageous.</p>

- Q: This question inquires about the potential differences in cooking performance when using various types of aluminum foil.

- <p>Yes, there are differences in cooking performance between different types of aluminum foil. The thickness of the foil can affect heat distribution and cooking time; heavier gauges are more durable and better for roasting and baking, while thinner foils are suitable for lining pans or wrapping foods. The quality of the foil, such as whether it's non-stick or not, can impact food release and cleanup. Additionally, some aluminum foils are designed to be heat resistant up to higher temperatures, making them suitable for broiling or grilling, while others may not withstand such high heat. It's important to use the appropriate type of aluminum foil for the specific cooking method to ensure food safety and optimal results.</p>

Send your message to us

Aluminum 18 Gauge Flat Circle 1070/1060/1050 for Spinning, Pressing, Deep Drawing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords