3105 Aluminum Coil Manufacture - High Quality Aluminum Coil/ Aluminum Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Coil

1) Alloy | AA1050, AA1060, AA1070, AA1100, AA3003, AA3004, AA3105, AA5005, AA5052, AA8011, AA8079 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum |

7) Coil Inner diameter | 76mm, 152mm, or as required |

2. Application of Aluminum Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of Aluminum Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

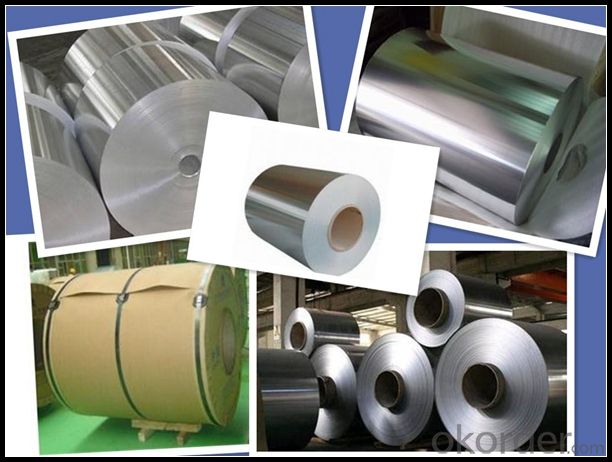

5. Image of Aluminum Coil

6. About Our Company

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 30 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

4)What are your payment terms?

We accept L/C, D/A, D/P, T/T, West Union,etc.

- Q: How long do aluminum coils typically last?

- The typical lifespan of aluminum coils is approximately 15 to 20 years, but their longevity is heavily influenced by various factors including the quality of the aluminum, the installation process, and the maintenance and care given to them. The lifespan of the coils can be significantly prolonged by regularly maintaining them, such as by cleaning the coils and ensuring adequate airflow. Moreover, their durability can also be affected by environmental factors like exposure to severe weather conditions and corrosive substances. Hence, ensuring proper care and maintenance is crucial to guarantee the extended lifespan of aluminum coils.

- Q: What is the role of aluminum coils in the construction of sports stadiums?

- Due to their advantageous properties, aluminum coils play a vital role in the construction of sports stadiums. Primarily, aluminum's lightweight nature makes it an excellent option for large-scale structures like stadiums. By utilizing aluminum coils during stadium construction, transportation and installation become easier, resulting in reduced construction time and costs. Moreover, aluminum possesses high resistance against corrosion, which is particularly advantageous in outdoor environments where stadiums are exposed to harsh weather conditions. This corrosion resistance ensures the longevity and durability of the stadium's structure, thereby minimizing maintenance and repair expenses over time. Furthermore, aluminum coils exhibit exceptional thermal conductivity, allowing for efficient heat transfer and effective temperature regulation within the stadium. This feature becomes especially significant in modern stadiums that require climate control systems to ensure the comfort of both players and spectators. Additionally, aluminum's high malleability enables it to be easily shaped into various forms and sizes, offering flexibility in stadium design and construction. This versatility empowers architects and engineers to create innovative and visually appealing structures, ultimately enhancing the overall aesthetic experience for visitors. In conclusion, aluminum coils play a multifaceted role in the construction of sports stadiums. They provide a lightweight, corrosion-resistant, thermally conductive, and malleable material that facilitates efficient construction, durability, comfort, and aesthetic appeal.

- Q: Is it advisable to use a hammer to open a stuck aluminum coil?

- <p>Using a hammer to break open an aluminum coil that is stuck closed is not recommended. Aluminum is a soft metal and can be easily damaged by blunt force. Instead, try using pliers or a screwdriver to gently pry open the coil. If the coil is rusted or stuck due to other reasons, applying a penetrating oil or lubricant might help loosen it without causing damage. Always prioritize safety and the preservation of the material when attempting to open or unstick objects.</p>

- Q: How are aluminum coils used in the production of signage and displays?

- Aluminum coils are widely used in the production of signage and displays due to their versatility, durability, and cost-effectiveness. These coils are typically made from high-quality aluminum alloy, which provides excellent strength and resistance to corrosion. In the production process, aluminum coils are first unwound and then passed through a series of rollers to achieve the desired thickness and shape. This process, known as coil coating or pre-painting, allows for the application of various finishes and coatings onto the surface of the aluminum. These coatings can include polyester, polyurethane, fluorocarbon, or acrylic, depending on the specific requirements of the signage or display. Once the aluminum coils are coated, they can be further processed into different forms, such as flat sheets, strips, or even customized shapes based on the design requirements. The versatility of aluminum allows for easy fabrication and customization, making it a popular choice for signage and display manufacturers. Aluminum coils are commonly used in a wide range of signage applications, including billboards, outdoor advertising panels, trade show displays, store signage, and architectural signage. The lightweight nature of aluminum makes it easy to transport and install, reducing production and installation costs. Moreover, aluminum's durability ensures that signage and displays made from aluminum coils can withstand harsh weather conditions, UV radiation, and other environmental factors, making them suitable for both indoor and outdoor applications. The corrosion-resistant properties of aluminum also contribute to the longevity of the signage, ensuring that it maintains its appearance and functionality over time. In addition to its physical properties, aluminum's aesthetic appeal is another reason for its extensive use in signage and displays. The smooth and reflective surface of the metal provides an attractive finish that enhances the visual impact of the signage, helping to grab attention and communicate messages effectively. Overall, aluminum coils play a crucial role in the production of signage and displays by offering versatility, durability, cost-effectiveness, and aesthetic appeal. Their ability to be easily customized, combined with their resistance to corrosion and harsh environmental conditions, makes aluminum an ideal material for creating eye-catching and long-lasting signage and display solutions.

- Q: Is it possible to utilize a punching machine to create holes in steel coils for decorative purposes?

- <p>Yes, you can use a punching machine to punch holes in steel coils for decoration purposes. Punching machines are designed to create precise holes in various materials, including steel. For steel coils, ensure the machine is capable of handling the thickness and hardness of the steel. It's important to select the right punch and die material, and consider the coil's strength and ductility. Always follow safety guidelines and machine specifications to prevent damage or injury.</p>

- Q: Is it safe and effective to use an electric stove to heat an aluminum coil?

- <p>Yes, you can use an electric stove to heat an aluminum coil. Aluminum is a good conductor of heat, so it will heat up when placed on an electric stove. However, it's important to ensure the coil is clean and free of any non-stick coatings that could be damaged by high heat. Also, be cautious of the temperature settings on your stove, as aluminum can melt at high temperatures. Always monitor the coil to prevent overheating or fire hazards.</p>

- Q: What are the rules and guidelines that govern the transport of aluminum coils?

- <p>Yes, there are specific regulations for the transportation of aluminum coils. These include adhering to weight limits, ensuring proper packaging to prevent damage, and following guidelines for secure loading and unloading. Compliance with hazardous materials regulations is also crucial if the coils are being transported internationally. It's important to check with the specific transportation authority or consult the International Air Transport Association (IATA) and International Maritime Dangerous Goods (IMDG) codes for detailed guidelines.</p>

- Q: How do aluminum coils compare to copper coils in terms of performance?

- Aluminum coils generally have lower thermal conductivity compared to copper coils, which can affect their performance in terms of heat transfer efficiency. Copper coils are more efficient at transferring heat, making them more effective in cooling and heating applications. However, aluminum coils are lighter and less expensive, which can make them a suitable choice for certain applications with budget constraints or weight limitations. Ultimately, the choice between aluminum and copper coils depends on the specific requirements and priorities of the system in which they are being used.

- Q: Does anyone know of any men's deodorant that doesn't contain aluminum? It has to be strong, as I do sweat a lot.

- Go to old spice there the best

- Q: Can aluminum coils be used in the production of heat sinks?

- Indeed, the utilization of aluminum coils is applicable in the manufacturing process of heat sinks. Aluminum, owing to its remarkable thermal conductivity and affordability, enjoys widespread usage as a material for heat sinks. These heat sinks are efficiently employed in the dissipation of heat emanated from electronic components like processors, power transistors, and LED lights. The coils can be fabricated into diverse forms and dimensions to fulfill particular heat dissipation prerequisites. Furthermore, aluminum possesses the advantages of being lightweight, resistant to corrosion, and readily accessible, rendering it an optimal selection for the production of heat sinks.

Send your message to us

3105 Aluminum Coil Manufacture - High Quality Aluminum Coil/ Aluminum Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords