Large Sheets of Aluminum Coil 5754 5005 8079 8011 1050 1060 for Cans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Pattern: orange peel, aluminum sheet5 bar,half a ball,diamond,compass shape

1.Orange peel aluminum sheet/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052

2)Temper :0 H114 H24 H32

3) Specification thickness:0.2mm-3.0mm

width:50mm-1300mm

Length: according your request

4)Application: Refrigeration. Air-conditioner. keep warm well such as pipe ,tank

5)Surface: No crack,canker, hole

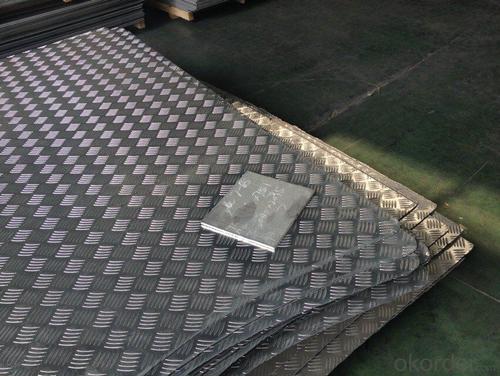

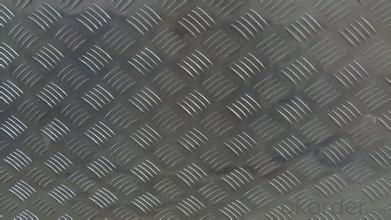

2. aluminum sheet5 bar/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

3.Compass shape aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: thickness:1.0mm-10mm

width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

4.Diamond aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: building industry,packing,decorative

5)Surface: No crack,canker, hole

4) Delivery time: 15-20 days after confirming order.

For all above:

1) Minimum order quantity: 5 tons per size.

2) The term of payment: T/T, irrevocable L/C at sight.

3) Packing: Export standard, waterproof wooden,craft,plywood pallet,etc.

- Q: Are aluminum sheets suitable for outdoor uses like fences or signs?

- <p>Yes, aluminum sheets are commonly used for outdoor applications such as fences and signage. Aluminum is lightweight, durable, and resistant to corrosion, making it ideal for outdoor conditions. It can withstand various weather elements without rusting. Additionally, aluminum can be easily formed into different shapes and sizes, and it's available in a wide range of colors and finishes, which makes it versatile for both functional and aesthetic purposes in outdoor settings.</p>

- Q: What are the advantages of using aluminum sheet in construction?

- There are several advantages to using aluminum sheet in construction. Firstly, aluminum is lightweight, making it easier to handle and transport compared to other materials. Secondly, it is highly resistant to corrosion, which ensures durability and longevity of structures. Additionally, aluminum is a good conductor of heat and electricity, making it suitable for various applications such as electrical wiring. Lastly, aluminum is recyclable, making it an environmentally friendly choice for construction projects.

- Q: What are the different types of surface treatments for aluminum sheets in the marine industry?

- Aluminum sheets are extensively utilized in the marine industry due to their lightweight nature and resistance to corrosion. To enhance their durability and performance in marine environments, various surface treatments are employed. These treatments provide an added layer of protection against corrosion, oxidation, and other types of wear and tear. Several surface treatments are available for aluminum sheets in the marine industry. One common treatment is anodizing, which involves an electrochemical process that creates an oxide layer on the aluminum surface. This layer adds strength, improves corrosion resistance, and can be dyed for aesthetic purposes. Another method is powder coating, which enhances the appearance and durability of aluminum sheets. It involves applying a dry powder to the surface and heating it to create a protective coating. Powder coating offers excellent resistance against corrosion, UV rays, and scratches. Chromate conversion coating, also known as chemical film coating or chromating, is another surface treatment option. This process immerses the aluminum sheets in a solution containing chromate compounds, forming a thin layer of chromate conversion coating on the surface. This enhances corrosion resistance and provides a suitable base for subsequent painting or bonding. Paint coating is another surface treatment method in the marine industry. It not only enhances appearance but also protects against corrosion, saltwater, and harsh environmental conditions. Epoxy or polyurethane-based paints are commonly used for marine applications. Mechanical treatments, such as brushing, grinding, or polishing, can also be performed on aluminum sheets to improve their surface finish. These treatments remove impurities, smooth out imperfections, and enhance the overall appearance of the aluminum surface. Each surface treatment has its own advantages and is chosen based on the specific requirements of the marine application. By selecting the appropriate treatment, manufacturers can ensure that aluminum sheets meet the necessary performance and durability standards in the demanding marine industry.

- Q: How do aluminum sheets perform in terms of electrical insulation?

- Aluminum sheets have poor electrical insulation properties as they are highly conductive materials.

- Q: Can aluminum sheets be used for wall cladding?

- Yes, aluminum sheets can be used for wall cladding. Aluminum is a popular choice for cladding materials due to its lightweight nature, durability, and corrosion resistance. It is commonly used in commercial and residential buildings for wall cladding as it provides an attractive and modern aesthetic to the exterior of a structure. Aluminum sheets can be easily formed and fabricated into various shapes and sizes, allowing for flexibility in design. Additionally, aluminum cladding is low maintenance, requiring minimal cleaning and upkeep. Overall, aluminum sheets are a versatile and practical choice for wall cladding.

- Q: What are the maximum dimensions of aluminum sheets?

- The maximum dimensions of aluminum sheets can vary depending on the specific manufacturing capabilities and requirements. However, commonly available aluminum sheets often have a maximum width of around 72 inches (6 feet) and a maximum length of approximately 240 inches (20 feet).

- Q: What are the different cutting tools used for aluminum sheets?

- There are several cutting tools that can be used for aluminum sheets. 1. Circular Saw: A circular saw with a carbide-tipped blade can be used to cut aluminum sheets. It is important to use a blade with fine teeth to ensure a clean and smooth cut. 2. Jigsaw: A jigsaw equipped with a metal-cutting blade can also be used to cut aluminum sheets. This tool allows for more intricate cuts and curves. 3. Bandsaw: A bandsaw with a fine-toothed blade is another option for cutting aluminum sheets. It provides a straight and precise cut, making it ideal for larger or thicker sheets. 4. Shears: Electric or manual shears can be used to cut aluminum sheets. They are particularly useful for straight cuts and can achieve a clean finish. 5. Plasma Cutter: A plasma cutter can be used for cutting aluminum sheets, especially for thicker materials. It uses high-temperature plasma to melt through the metal, resulting in a precise and efficient cut. 6. Laser Cutter: Laser cutting machines are commonly used for cutting aluminum sheets. They produce a high-powered laser beam that melts and vaporizes the material, allowing for precise and intricate cuts. It is important to wear appropriate safety gear, such as gloves and goggles, when using any of these cutting tools. Additionally, choosing the right tool depends on the thickness of the aluminum sheet and the desired cut. It is recommended to consult a professional or refer to the manufacturer's guidelines for the specific tool being used.

- Q: Can aluminum sheets be used for decorative wall panels?

- Yes, aluminum sheets can be used for decorative wall panels. Aluminum is a versatile material that offers a wide range of design options for wall panels. It is lightweight, durable, and resistant to corrosion, making it suitable for both interior and exterior applications. Aluminum sheets can be easily cut, formed, and fabricated into various shapes, patterns, and finishes, allowing for endless design possibilities. Additionally, aluminum can be powder-coated or anodized to enhance its appearance and provide additional protection against wear and tear. Whether it's for residential or commercial spaces, aluminum sheets can add a modern and stylish touch to any wall, making them a popular choice for decorative wall panels.

- Q: Can aluminum sheets be painted or coated with different colors?

- Yes, aluminum sheets can be painted or coated with different colors. Aluminum is a versatile material that can be easily painted or coated to achieve a desired aesthetic. The process of painting or coating aluminum involves applying a layer of paint or coating material onto the surface of the sheet. This can be done through various methods such as spraying, rolling, or dipping. The paint or coating material adheres to the aluminum surface, providing a protective layer and giving it a different color or finish. The ability to paint or coat aluminum sheets with different colors allows for endless possibilities in terms of customization and design options.

- Q: 1) Aluminum ore is not formed in Quebec (why not?) 2)but aluminum ore is smelted into aluminum in Quebec. Why?

- Bauxite is the most common aluminum ore. Bauxite forms in tropical regions because its formation requires intense weathering conditions (lots of frequent rainfall) with a very good drainage. Even if, due to continental drift, Quebec was once in a tropical region, it is highly unlikely that bauxite would have formed there because almost all of Quebec sits on the Canadian Shield. The Canadian Shield is a large region of very, very old rock that can be thought of as mostly monolithic and quite flat. Its monolithic nature makes it difficult to weather, and its flatness means that it doesn't drain as well as is needed to form bauxite. Smelting bauxite requires enormous amounts of electricity - not just any energy, but electricity. Quebec has enough hydroelectric resources to make this practical.

Send your message to us

Large Sheets of Aluminum Coil 5754 5005 8079 8011 1050 1060 for Cans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords