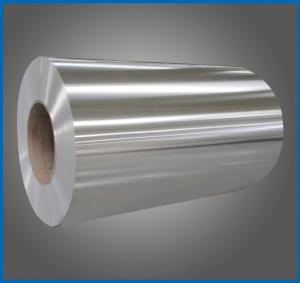

Aluminum Grating Sheets - Custom Aluminum Coil 5182 H19 for Drink Can Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification

| Alloy | Temper | Gauge(mm) | ||

3104 series 5182 series 5052 series | H19 | Thickness | Width | Length |

| 0.2-0.32 | 450-2000 | coil- at request | ||

2. Production Feature

Online CFF & DBF double classes filter system and on line ALPUR degassing system,

Melting purity excellent

Quality sustainable.

Cold rolling is mass flow controlled, size precise, shape well

Good deep drawability, small earing rate, good curing performance

4. Packing & Shipping

Wooden pallet and steel band packing

Eye to sky & eye to sky

Shipped in 20ft & 40ft containers

5. Product Standard

ASTM- B 209

EN485

GB3880.3-2012

JIS4000

6. Application

Products are widely used in wide range transportation, packing & printing, mechanical manufacturing, electronic communication, hardware molding, architectural decoration and etc.

- Q: Can aluminum sheets be utilized as a material for constructing caravan roofs?

- <p>Yes, aluminum sheets can be used for caravan roofs. They are lightweight, durable, and resistant to corrosion, making them an ideal material for this purpose. Aluminum sheets are easy to install and maintain, and they can also reflect heat, helping to keep the interior of the caravan cooler. However, it's important to ensure that the aluminum sheets are of good quality and properly sealed to prevent water ingress and to maintain structural integrity over time.</p>

- Q: Are the aluminum sheets suitable for manufacturing lightweight structures?

- Yes, aluminum sheets are highly suitable for manufacturing lightweight structures due to their low density and high strength-to-weight ratio.

- Q: How do I prevent corrosion on aluminum sheets?

- To prevent corrosion on aluminum sheets, several steps can be taken: 1. Regularly clean the aluminum sheets using a mild detergent or aluminum cleaner to eliminate any dirt, grime, or chemical residues present on the surface. This will prevent the accumulation of corrosive substances. 2. It is worth considering the application of a protective coating on the aluminum sheets. There are different types of coatings available, such as clear coats, anodizing, or painting. These coatings act as a barrier between the aluminum and the surrounding environment, effectively preventing corrosion. 3. Take care to avoid contact with corrosive substances. Aluminum can be susceptible to corrosion when exposed to certain chemicals like acids, alkalis, or saltwater. Be mindful of the environment in which the aluminum sheets are stored or utilized and steer clear of exposure to these corrosive substances. 4. Store the aluminum sheets in a dry environment with low humidity levels. Moisture can accelerate the corrosion process, so it is crucial to keep the sheets dry and protected from excessive moisture. 5. Consider implementing preventive measures such as using corrosion inhibitors or anti-corrosion sprays specifically designed for aluminum. These products can provide an additional layer of protection against corrosion, particularly in harsh or corrosive environments. By adhering to these preventive measures, the risk of corrosion on aluminum sheets can be significantly reduced, effectively extending their lifespan.

- Q: Can aluminum sheets be perforated for decorative or functional purposes?

- Yes, aluminum sheets can be perforated for both decorative and functional purposes. Perforating aluminum sheets allows for the creation of intricate patterns or designs and also enhances the sheet's functionality by improving ventilation, reducing weight, or enhancing acoustic properties.

- Q: Are aluminum sheets suitable for electrical conductors?

- Aluminum sheets are indeed suitable for electrical conductors. They are frequently employed as conductors in a variety of electrical applications due to their remarkable conductivity, lightweight nature, and relatively low cost in comparison to metals such as copper. With approximately 61% of copper's conductivity, aluminum serves as an efficient conductor for most electrical purposes. Power transmission lines, electrical wiring, bus bars, and numerous other electrical components commonly utilize aluminum sheets. However, it is crucial to acknowledge that aluminum possesses higher resistance than copper, necessitating larger cross-sections to carry the same current. Additionally, caution must be exercised to prevent overheating when employing aluminum sheets as electrical conductors, as they have a lower melting point than copper.

- Q: What characteristics distinguish aluminum sheets from other types of sheets?

- <p>Aluminum sheets are lightweight, corrosion-resistant, and have excellent thermal and electrical conductivity. They are commonly used in construction, automotive, and packaging industries. In contrast, other types of sheets, such as steel sheets, are heavier and stronger but less resistant to corrosion. Plastic sheets are lightweight and flexible but have lower strength and thermal conductivity. Copper sheets offer high thermal and electrical conductivity but are more expensive and less resistant to corrosion than aluminum. Each type of sheet has unique properties that make it suitable for specific applications.</p>

- Q: Are 101 aluminum sheets suitable for architectural louvers or sunscreens?

- Yes, 101 aluminum sheets are suitable for architectural louvers or sunscreens. They possess excellent strength, durability, and corrosion resistance, making them ideal for outdoor applications. Additionally, their lightweight nature allows for easy installation and maintenance.

- Q: Can the aluminum sheets be painted or coated with a different color?

- Yes, aluminum sheets can be painted or coated with a different color. Aluminum is a versatile material that can be easily painted or coated to achieve a desired color or finish. This can be done through various methods such as powder coating, anodizing, or using liquid paint. These processes provide a protective layer on the surface of the aluminum sheet while giving it a different color or appearance. The choice of paint or coating will depend on the specific requirements and desired outcome. Overall, painting or coating aluminum sheets is a common practice and allows for customization and aesthetic enhancement.

- Q: what kind of aluminum sheet is suitable for aluminum alloy double-edged saw?

- general horizontal driving sawing and precision sawing.

- Q: Can aluminum sheets be welded or joined together?

- Yes, aluminum sheets can be welded or joined together using various welding techniques such as TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), or spot welding.

Send your message to us

Aluminum Grating Sheets - Custom Aluminum Coil 5182 H19 for Drink Can Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords