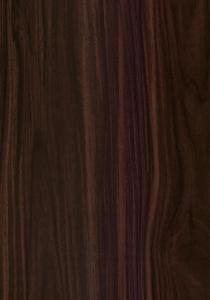

Aluminum Coil 3003 with Wood Grain Coating

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium coated sheetand coil choose aluminium sheet coil as raw material, after de-ester, cleaning,passivation layer processing, and then painting on this basis, the paint areprovided by famous international companies like PPG and Valspar from UnitedStates or Becker from Sweden, represent the most advanced level in the world.After the test of exposure by natural light in Florida, the quality assurance is more than morethan 20 years. As poor performance of color coated steel corrosion, rust,yellow rust after a large amount of the deficiency of serious impact on thebuilding's overall appearance. However, because of the advantages of rawmaterials, Aluminium coated coil have a high strength, corrosion resistance,high weather resistance, can be used recycle, save energy and protect theenvironment and other characteristics. Not only have the same strength with colorcoated steel, but also overcome the shortage of color coated steel. So, the Aluminiumcoated coil has been widely used as roofing and ceiling decorative envelopesystem board in modern constructions like large factories, exhibition halls,stadiums, airports, train station hospital and so on. We can choose Aluminiumcoated coil in different thickness and color, by cutting, pressing, punching,bending and other follow-up molding process for large span, the larger theoverall roofing, wall decorative panels used in construction; or cut them intosmall panels by bending, stamping mold or other processing for indoordecorative roofing plate; we can also composite them with polyurethane foam oraluminium honeycomb for energy-saving decorative wall plates.

Alloy | 1050,1060,1100,3003,3004,3005,3104,3105,5052,5005,8011 |

Temper | O,H42,H44,H46,H48 |

Thickness (mm) | 0.25mm-1.5mm for aluminium coated coil; 1.50mm-4.0mm for aluminium coated sheet. |

Width (mm) | 100mm to 2000mm |

Length (mm) | 800mm to 6000mm for sheet |

- Q: Can aluminum coils be used in the production of heat exchangers?

- Yes, aluminum coils can be used in the production of heat exchangers. Aluminum is a commonly used material in heat exchangers due to its excellent thermal conductivity, lightweight nature, and corrosion resistance. The use of aluminum coils allows for efficient heat transfer and helps in optimizing the overall performance of the heat exchanger.

- Q: We are shopping for a new LQ trailer. We are looking at several different brands and noticed that some have aluminum skin on an aluminum frame, and others have aluminum skin on a steel frame. Other than the obvious differences in weight and cost, what are other benefits/disadvantages of each? Thanks

- Aluminum Trailer Frames

- Q: What does 1060 of the 1060 Aluminum rolls stand for?

- Purity can reach more than 99%. Because it does not contain other technical elements, the production process is relatively simple, and the price is relatively cheap. It is the most commonly used series in the conventional industries.

- Q: Is it possible to utilize aluminum coils in the process of water treatment?

- <p>Yes, aluminum coils can be used for water treatment. They are often used in processes such as coagulation and flocculation, where aluminum salts are added to the water to help remove suspended particles and impurities. The aluminum ions react with the particles in the water to form larger, heavier particles that can be more easily settled or filtered out. Additionally, aluminum coils can be part of an electrode system in electrocoagulation processes, where an electric current is used to treat water by generating aluminum ions at the anode. This method is effective for removing various contaminants, including heavy metals, bacteria, and organic compounds.</p>

- Q: Are there any specific installation requirements for aluminum coils?

- Aluminum coils have specific installation requirements that must be taken into account. When installing these coils, several factors need to be considered. First and foremost, it is crucial to provide adequate support and secure the coils properly during installation. Due to their weight, it is essential to prevent sagging or damage by using appropriate brackets or support structures. This ensures that the coils are firmly mounted. Secondly, the location and environment of the installation should be carefully assessed. Aluminum coils are commonly used in HVAC systems, so it is important to ensure that the installation area is free from any corrosive substances or chemicals that could harm the coils. Additionally, proper ventilation is necessary to prevent the accumulation of heat or moisture, as these factors can affect the coils' performance and lifespan. Moreover, it is imperative to adhere to the manufacturer's guidelines and recommendations for installation. These guidelines may include specific instructions regarding the type of fasteners or connectors to be used, the appropriate spacing between coils, and any other particular requirements for the specific aluminum coil being installed. By following these guidelines, the coils' optimal performance and longevity can be ensured. Lastly, it is highly advisable to enlist the services of a professional with experience in handling and installing aluminum coils. This will minimize the risk of any issues or damage resulting from incorrect installation. In conclusion, specific installation requirements for aluminum coils encompass proper support, consideration of the installation environment, adherence to manufacturer guidelines, and professional installation. By following these requirements, the optimal performance and longevity of aluminum coils can be achieved.

- Q: I have been reading up on thermite and the required ingredients. I have extremely fine aluminum powder from a small etch-a-sketch sitting on plastic wrap in my room. On the comments page of the site i got the thermite ingredients from, multiple people said that thermite could explose if you use too fine of a powder. I have also read that powdered aluminum can become very explosive when it is exposed to air or if it becomes damp. Ive gotten particulary worried because the humidity right now is 93%. So, is powdered aluminum too dangerous to have in house and is too fine powdered aluminum explosive when in thermite?

- Powdered aluminium isn't explosive, and any humidity or dampness in the air won't affect it. Really finely powedered aluminium is nothing but an extremely powerful reducing agent. In other words, it won't explode, but it will burn very fast and very hot. When combined with magnesium powder, it contributes to the nature of thermite in a reduction-oxidation reaction. On it's own however, as long as you keep it away from any open flames, it's perfectly safe. I should say; be very, very careful with making thermite. It's not explosive on it's own, but if you make it wrong, it can fizzle and pop and send molten metal flying your way.

- Q: Are aluminum coils easy to install?

- Yes, aluminum coils are generally easy to install. They are lightweight and flexible, which makes them easier to handle and maneuver during installation. They can be easily cut and shaped to fit the specific requirements of the installation, and they are often available in pre-cut sizes, further simplifying the installation process. Additionally, aluminum coils are typically designed with features such as interlocking edges or snap-on connectors, which make it easier to join multiple coils together or connect them to other components. Overall, with the right tools and basic knowledge of HVAC installation, aluminum coils can be installed relatively easily.

- Q: How are aluminum coils annealed?

- Aluminum coils are typically annealed through a process known as heat treatment. This involves heating the coils to a specific temperature and then slowly cooling them down. The purpose of annealing is to soften the aluminum and improve its ductility, making it easier to work with. The first step in annealing aluminum coils is to clean them thoroughly to remove any contaminants. The coils are then placed in a furnace, which is heated to the desired temperature. The temperature and duration of the annealing process depend on the specific grade and thickness of the aluminum being treated. Once the coils reach the desired temperature, they are held at that temperature for a predetermined amount of time. This allows for the internal structure of the aluminum to become more uniform and relieves any internal stresses that may have developed during the manufacturing process. After the annealing process is complete, the coils are slowly cooled down in the furnace. This slow cooling is important to prevent the formation of any new internal stresses. Once the coils have cooled to room temperature, they are ready for further processing or use. In some cases, a process known as quenching may be used after annealing. Quenching involves rapidly cooling the aluminum by immersing it in a quenching medium, such as water or oil. This can help to further improve the mechanical properties of the aluminum, such as its strength and hardness. Overall, the annealing process for aluminum coils is a carefully controlled heat treatment that aims to improve the metal's properties and make it more suitable for various applications.

- Q: Are aluminum coils suitable for food storage containers?

- Aluminum coils are indeed appropriate for food storage containers. This material is highly favored for such containers because of its many beneficial qualities. To begin with, aluminum is lightweight, which makes it easy to handle and transport. Moreover, it possesses excellent thermal conductivity, allowing for quick heating or cooling, making it perfect for storing both hot and cold food. Additionally, aluminum is resistant to corrosion and does not react with acidic or alkaline foods, ensuring that the taste and quality of the food remain unaffected. Furthermore, aluminum is an environmentally friendly choice as it is sustainable and can be recycled. However, it is worth noting that aluminum containers should be coated with a food-grade lining to prevent any potential interaction between the metal and the food, particularly with acidic foods. In conclusion, aluminum coils are a suitable option for food storage containers due to their lightweight nature, thermal conductivity, resistance to corrosion, and recyclability.

- Q: This question asks about the distinctions among various grades of aluminum coils, likely referring to their properties and uses.

- <p>Aluminum coils are differentiated by grades based on their alloy composition, thickness, and specific applications. Common grades include 1000 series (99% pure aluminum, soft and malleable), 3000 series (aluminum-manganese alloys, good for cooking utensils), 5000 series (aluminum-magnesium alloys, used in marine applications), and 6000 series (aluminum-magnesium-silicate alloys, known for strength and used in construction). Each grade has distinct properties such as strength, formability, and corrosion resistance, which determine their suitability for different industries and applications.</p>

Send your message to us

Aluminum Coil 3003 with Wood Grain Coating

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords