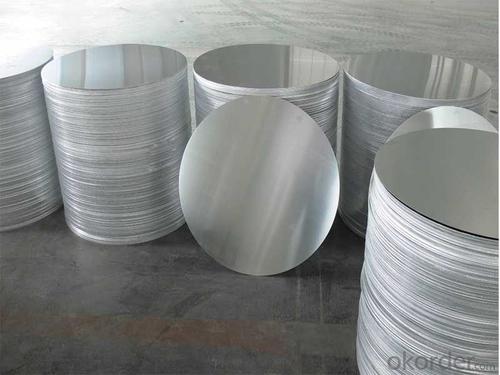

Industrial Aluminum Circle for Spot Welding Aluminum Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

- Q: This question asks for methods to prevent aluminum sheets from warping or curling during processing or storage.

- <p>To prevent aluminum sheets from warping or curling, ensure proper storage by keeping them flat and avoiding stacking them under heavy loads. Maintain a controlled environment with consistent temperature and humidity to prevent expansion and contraction. When cutting, use sharp tools to minimize heat generation and stress. Apply a stress-relieving process after fabrication to reduce internal stresses. Use appropriate jigs and fixtures during fabrication to maintain flatness. Finally, consider the thickness and alloy of the aluminum sheet, as some are more prone to warping than others.</p>

- Q: How do you join aluminum sheets together?

- One common method to join aluminum sheets together is through welding. This involves melting the aluminum at the joint and then allowing it to solidify, creating a strong bond. Other methods include using adhesive bonding, riveting, or using mechanical fasteners such as screws or bolts. The choice of joining method depends on factors such as the application, the thickness of the aluminum sheets, and the desired strength and appearance of the joint.

- Q: Can aluminum sheets be brushed or satin finished?

- Yes, aluminum sheets can be brushed or satin finished. Brushing or satin finishing is a process that involves creating a textured surface on the aluminum sheets. This can be achieved by using abrasive materials, such as sandpaper or wire brushes, to create a pattern of fine lines or scratches on the surface of the metal. This process is often used to enhance the appearance of aluminum sheets by giving them a more matte and textured finish. Additionally, brushing or satin finishing can also help to hide small imperfections or scratches on the surface of the aluminum sheets. Overall, the ability to brush or satin finish aluminum sheets provides flexibility in terms of achieving desired aesthetics and surface textures for various applications.

- Q: Explain how the use of aluminum sheets can impact the energy efficiency of a building.

- <p>Aluminum sheets can significantly affect a building's energy efficiency due to their excellent thermal conductivity and reflective properties. They can be used in building construction to form a barrier against heat transfer, reducing the need for heating and cooling. Additionally, aluminum's reflective surface can help in reflecting sunlight, thereby reducing heat gain in the building. However, if not properly insulated, aluminum's high conductivity can lead to heat loss, reducing energy efficiency. Therefore, the use of aluminum sheets in buildings often requires a balance between their heat-reflective and heat-conductive properties to optimize energy efficiency.</p>

- Q: What is the typical weldability of aluminum sheets?

- Aluminum sheets have good weldability due to their high thermal conductivity and low melting point.

- Q: What are the different methods of surface protection for outdoor aluminum sheet?

- There are several methods of surface protection for outdoor aluminum sheets. One common method is painting the surface with a protective coating, such as a weather-resistant paint or powder coating. Another method is anodizing, which involves creating a durable oxide layer on the surface of the aluminum. Additionally, applying a clear protective film or using a protective sealant can also help protect the aluminum sheet from outdoor elements.

- Q: If I were to make an aluminum mold and cover it with a release agent, could I cast aluminum into it? Or would the two parts fuse together? I'm trying to find an alternative to sand casting.Thank you!

- This may be a little more difficult but offers better detail than sand casting. Lost wax casting Investment or ceramic shell You can make molds to form the wax but investment or ceramic shell are destroyed in the process

- Q: Are aluminum sheets suitable for pharmaceutical applications?

- Yes, aluminum sheets are suitable for pharmaceutical applications. They are commonly used for packaging pharmaceutical products due to their excellent barrier properties, lightweight nature, and resistance to corrosion. Aluminum sheets help to protect the contents from moisture, oxygen, and light, ensuring the stability and effectiveness of pharmaceutical drugs. Additionally, aluminum sheets can be easily formed into different shapes, making them ideal for creating blister packs, caps, and closures for pharmaceutical packaging.

- Q: If you're familiar with some of my previous questions, you'll know I have a thing for DC-3's, and I'd like to buy one and fix it up at some point in my life. I was looking at pictures on Google for my desktop background and saw several with shiny chrome/aluminum bodies. Well, first of all, is it chrome or polished aluminum? Second, would I be able to buy a DC-3 painted this God-awful forest green and put whatever it is (chrome/aluminum) on said plane? Or is it something that the plane has to be built with originally?

- Polished aluminum, get a couple heavy duty buffers and some for your friends and then buy stock in Flitz. You can also get it where you want it and paint it with clearcote to keep it a littl better, or what most do; paint it a light gray or silver color. You can strip it, but strip and paint is not cheap. Also, since the controls are fabric covered, they will never match the polished fuselage, that's why paint is better.

- Q: What are the typical uses or applications for 101 aluminum sheets?

- 101 aluminum sheets are commonly used in a variety of applications such as roofing, siding, gutters, and general construction due to their excellent corrosion resistance, high formability, and durability. They are also utilized in the automotive industry for body panels, trims, and interior components. Additionally, 101 aluminum sheets are often used for packaging, electrical enclosures, and kitchen equipment due to their lightweight nature and ability to withstand various environmental conditions.

Send your message to us

Industrial Aluminum Circle for Spot Welding Aluminum Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords