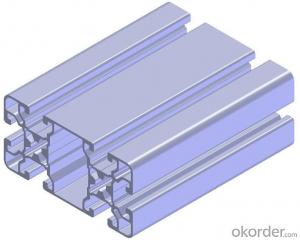

Aluminum Any Use Product

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 μm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

- Q: Use of aluminium strips for aluminium strips

- 1060 requirements of corrosion resistance and formability are high, but the strength requirements are not high, chemical equipment is its typical use1100 for processing requires good formability and high corrosion resistance but is not required to have high strength parts, such as chemical products, food industry device and storage containers, sheet processing, deep drawing or spinning concave ware, welding parts, heat exchanger, printing plate, nameplate, reflective instruments3004 plates, thick plates, tensile tubes. For as long as extruded tube aluminum cans cans, requires much higher than the 3003 alloy parts, chemical products production and storage device, sheet processing, building baffle, cable conduit, sewer, various lighting components.

- Q: i have made a zebra head out of regular paper mache ( to be used as a mask )i plan on making many copies, so making multiple heads out of paper mache would take up a long timeso i thought i could use my paper mache head as a mold, then apply spackling to the surface, and then make copies by removing and repeatingwill spackling dry up like paper mache ?or am i better off just buying plaster ?

- You won't die, but frostbite can become an issueSleep with a hat on, gloves, and good socksPreferably woolNo alcohol or caffeineAnd stay dry.

- Q: What are the thermal properties of aluminum profiles?

- The thermal properties of aluminum profiles are quite favorable due to the inherent characteristics of aluminum as a metal. Aluminum has a high thermal conductivity, which means it can transfer heat quickly and efficiently. This property makes aluminum profiles ideal for applications that require heat dissipation or thermal management. Moreover, aluminum profiles have a low coefficient of thermal expansion, meaning they expand and contract minimally with changes in temperature. This makes aluminum profiles highly stable and resistant to warping or distortion, even under extreme temperature variations. Additionally, aluminum profiles have a relatively low melting point compared to other metals, making them suitable for applications that involve high operating temperatures. The ability of aluminum to withstand high temperatures without losing its structural integrity further enhances its thermal properties. Furthermore, aluminum profiles exhibit good thermal insulation properties, as they do not conduct heat easily. This makes them suitable for applications that require thermal insulation or the prevention of heat transfer, such as in building and construction or HVAC systems. Overall, the thermal properties of aluminum profiles, including high thermal conductivity, low coefficient of thermal expansion, high melting point, and good thermal insulation, make them highly versatile and widely used in various industries, ranging from automotive and aerospace to electronics and construction.

- Q: my hair is really dry from straightening and stuff, any shampoos or conditioners that make your hair really soft?

- 2 and 1 2 hours bowling

- Q: I dont have cream soup, but I do have chicken bullion and spices? please help I googled but didnt really find anythingLinks would be great.

- BAKED CHICKEN AND RICE 1 whole or cut-up baking chicken 1 craw rice, quick or regular 1 can cream of chicken soup or cream of mushroom soup 1 can water 1 tbspbutter Line casserole with aluminum foilPour raw rice in bottom of dishPlace chicken on riceIn separate bowl, mix one can of cream of chicken soup with 1/2 cup waterPour over chickenDot with butterCover casserole with foilBake at 350 degrees for 1 to 1 1/2 hoursNOTE: This can remain in cooling oven for up to an hourTo brown, it may be placed under broiler for 10 minutesServes 4 to 6.

- Q: Are aluminum coils available in different colors?

- Yes, aluminum coils are available in different colors. The process of coloring aluminum coils involves coating the surface with a durable finish that can be in various colors. This coating is typically achieved through a process called coil coating, where the aluminum coil is cleaned, pre-treated, and then coated with a layer of paint or other colored material. This allows for a wide range of colors to be applied to the aluminum coils, providing flexibility in design and aesthetic options for various applications.

- Q: Are the aluminum sheets suitable for manufacturing marine propellers?

- Yes, aluminum sheets are suitable for manufacturing marine propellers. Aluminum is a lightweight and corrosion-resistant material, making it an excellent choice for marine applications. It offers good strength-to-weight ratio, high durability, and can withstand harsh saltwater environments. Additionally, aluminum propellers are known for their efficient performance and cost-effectiveness.

- Q: What is the chemical composition represented by the formula for aluminum strips?

- <p>The chemical formula for aluminum strips is simply Al. Aluminum is a chemical element with the symbol Al and atomic number 13. It is a silvery-white, soft, nonmagnetic, and ductile metal in group 13 of the periodic table. Aluminum strips are made of this single element and do not contain any other elements or compounds.</p>

Send your message to us

Aluminum Any Use Product

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches