1/0 1/0 1/0 Aluminum Wire for Window Screen Woven Mesh

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Alloy Wire Description:

Aluminum Alloy Wire is acid and alkali resistant, corrosion resistance, high strength, good toughness, and it does not fade at high temperatures (120 ℃). So products with aluminum-magnesium alloy micro wire would not deform easily, and there is a good shielding effect.

Featured by small density and high strength, the aluminum magnesium alloy tool is the lightest metal component material at present. Aluminum magnesium alloy wire can be used for core wire (as a substitution of copper wire) and shielding weaving wire which are widely applied to all kinds of communication cables, coaxial cables, being the supporting products of broad band transmission network and communication network.

2.Main Features of the Aluminum Alloy Wire

The wire is no oil stain on the wire surface

The wire surface is very smooth, and there is no burrs

The wire is very beautiful

The wire surface is bright

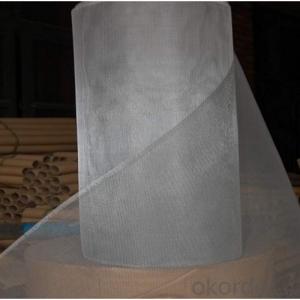

3.Aluminum Alloy Wire Images

4.Aluminum Alloy Wire Specification

Alloy | Uyimate Tensile Strength (PSI) | Electrical Resistance | Density (g/cc) | Melting Point |

1100 | 13000 | 18 | 2.71 | 645° |

1350 | 13000 | 17 | 2.70 | 648° |

1199 | 6800 | 15 | 2.70 | 660° |

2024 | 27000 | 20.25 | 2.78 | 638° |

3003 | 16000 | 20.25 | 2.73 | 654° |

4043 | 21000 | 25 | 2.69 | 632° |

5005 | 18000 | 19.95 | 2.70 | 654° |

5052 | 28000 | 10.2 | 2.68 | 649° |

5056 | 42000 | 36 | 2.64 | 605° |

6061 | 17000 | 22 | 2.70 | 617° |

5.FAQ

1) What is quality?

We are a state-owned company and ranked No267th of Fortune 500 in 2014. There is no need of worry about quality.

2) How is your delivery time:

In General, it will take 25days

3) How about your service?

We have a professional Inspection Team.

- Q: The similarities and differences between aluminum wire and copper wire

- Color, conductivity, densityPure metallic copper; purplish red; not pure; may be golden or brown

- Q: Common causes and treatment of LED light flashing

- This is the bad contact LED lamp gold or aluminum wire, usually, a welding wire connecting wire, arc welding off, if the two did not fill ball there may be two welding welding.

- Q: Which heat transfer is copper wire, wire or aluminum wire fast?

- The thermal conductivity of brass is 92.8 W/ (M2 * K); the thermal conductivity of aluminum is 203 W/ (M2 = K); the heat conductivity of mild steel is 46.4 W/ (M2 ? K)Therefore, the heat transfer speed: aluminum wire > copper wire > iron wire

- Q: This cable, which is copper wire, or aluminum wire, thank you all

- Look at the price, if it is of good quality, it will use copper wire or even silver plated wire

- Q: Is the polyurethane plastic made of transparent wrapped aluminum silk easy to yellow?

- If you want permanent resistance to yellowing, you can only use the aliphatic, but the price of this raw material is high.

- Q: Why is aluminum wire difficult to react with dilute sulfuric acid by hydrochloric acid reaction?

- Hypothesis: Aluminum Sulfate Precipitates attached on the surface of aluminum to stop the reaction to continue the experiment design: take a bar for a period of time, immersed in dilute sulfuric acid, to see bubbles continue to build out, wash or scrape the surface of aluminum white material, aluminum strip again immersed in dilute sulfuric acid, if again bubble formation the hypothesis that.

- Q: What is the material of the toilet with aluminium drawing effect?

- One is the pure aluminum wire drawing veneer, two substrates, one is particleboard, is a compact panel, water foaming board, the price is relatively low. Compact substrate pure aluminum wire drawing is good, waterproof and fire-resistant, moderate price. Recommend a factory to you, Wuhan B-win Yongsheng bathroom partition.

- Q: What is aluminum wire? What's the difference between aluminum wire and stainless steel?

- Aluminum wire is pure aluminum pulled into the wire, the material is aluminum, stainless steel is containing nickel chromium, titanium alloy steel, there is no difference between comparability, material difference is too big, not the same

- Q: Can the wire on the computer be exposed to electric shock?

- Cable (data), which is used to connect mobile devices and computers to achieve data transmission or communication purposes. Popular point of view, that is connected to the computer used to transmit bell, pictures and other types of file access tools.

- Q: Aluminum wirMay not be related to the type of lubricant chosen.e through the mold, why not bright?

- Suggest you use BW-500F aluminum acid degreasing agent, and BW-286 aluminum chrome free passivation agent collocation, the treatment of aluminum wire surface bright and form a layer of conductive passivation film, the effect is good.

Send your message to us

1/0 1/0 1/0 Aluminum Wire for Window Screen Woven Mesh

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords