Aluminum Wire Sizes - AA5052 Aluminium Wire for Package and Bending

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、 Structure of Aluminium Wire Description

Aluminium wire is widely used in ballasts automotive electronics, refrigerator and air

conditioner compressor motors, television sets, electric stove, microwave ovens, various transformers, and other kinds of electronic coil motors, electrical appliances.

2、Main Features of the AA5052 Aluminium Wire

Core number:one

Shape materials:Round

Elongation:>15%

Tensile strength:110MP-130MP

Paint:1730,1736,1745,1754

Packing:Carton

3、 Aluminium Wire Images

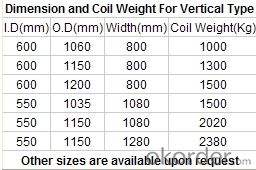

4、Aluminium Wire Specification

5、FAQ of AA5052 Aluminium Wire

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: Aluminum wire was inserted into copper sulfate solution without any phenomenon. What is the reason for this?

- Under normal circumstances, the aluminum wire is inserted into the copper sulfate solution, and the surface of the aluminum wire is plated with a layer of copper. No phenomenon occurred,

- Q: The outside of the frying pan is full of strong and thick layers of grease and stains. How can it be removed easily?

- The washing powder or clean water into the pot after the first precise use of cloth dipped in water to wipe it again, after a while and then brushed aluminum. Iron pot of the group of imitation aluminum wire (such as electric wire like) eraser, stained with washing powder, water wipe, no oil pollution. Our kitchen has not been cleaned for 5 years, it's dirty, and we have many ways to do it. Finally, we use this method to clean the kitchen. It is as white as new. You can try it!

- Q: How to remove the black dirt in the iron pan?

- Honey method. Apply a little honey to the dirt at the bottom of the pot, and clean it in half an hour with pan cloth.

- Q: Why not use copper, iron, aluminum wire instead of fuse?

- When the line is overloaded or the short-circuit current increases, the fuse is dissolved to cut off the current, protect the circuit and the electrical effect. If copper, iron, aluminum wire is used instead,

- Q: This cable, which is copper wire, or aluminum wire, thank you all

- In this way, wires of good quality are copper wires.

- Q: How to remove the thick dirt on the iron pan?

- Most housewives wash pot only wash do not wash the bottom surface is wrong, because the bottom covered with inverted vegetables when he returned alone, if not always wash residue at the bottom, bottom thickness gradually thickening in the course of time, the effect of cooking heat, so must be positive and negative, washed and then placed on a stove fire drying to remove water, next time also convenient.

- Q: Is the wire on the diode a type of P and N semiconductor? Or P semiconductor?

- One end of the fine aluminum wire is connected to the anode lead, and the other end is pressed on the doped n type semiconductor. After adding the voltage, the fine aluminum wire melts at the contact point and penetrates into the melted part. In this way, the contact point is actually a p type semiconductor and attaches to the N type semiconductor to form a PN junction.

- Q: How to properly install fuse

- When a fuse volume is not enough and needs to be used in parallel, each other can not be twisted together, and the size of the fuse shall be calculated.Do not pull the fuse too tight or too bent, so as to loosen it slightly.

- Q: How to choose argon arc welding machine?

- Wire feeding strength. Some manufacturers use the cheap, poor quality motor and adjustment system, the low-speed wire feeding force is not enough. 1.5 speed motor will not move, should choose to 0.1 motor in the test will also send wire, low speed wire feeding is stable kind, this is very important in the welding of thin plates, thin wire is need to slow, fast time to melt the wire feeding.

- Q: When fuse is blown, why not use copper wire and wire instead?

- Copper wire, aluminum wire, wire resistance is very low, small series power, it is not easy to heat, especially the high melting point of these materials, it is not easy to fuse

Send your message to us

Aluminum Wire Sizes - AA5052 Aluminium Wire for Package and Bending

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords