Aluminum Alloy Sheet for Construction and Semi Trailer Wall Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

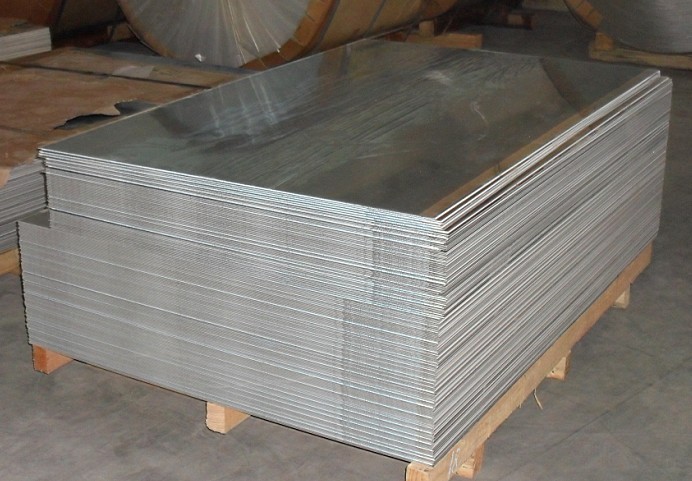

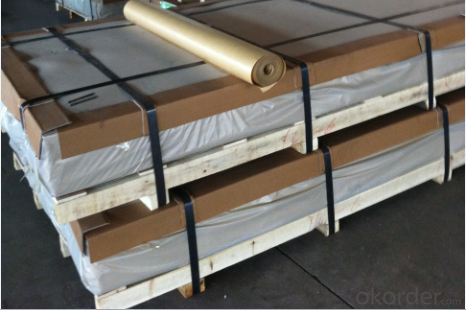

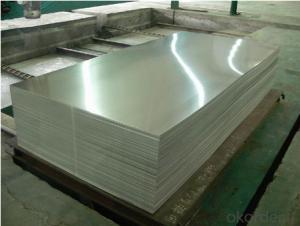

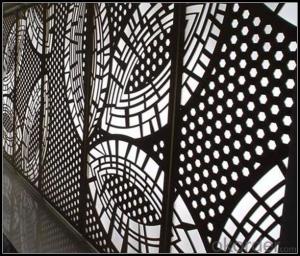

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: AND WAT R THE THECNOLOGICAL ANDCOSTS AND BENEFITESOF USING ALUMINUM? what health -related and environment-related issues gave surface as aresult of its widespread use in society?

- airplanes are made from aluminum. certain beverages are also. aluminum is cheaper and lighter. the biggest problem is the amount of electricity that it takes to make aluminum

- Q: 2mm aluminum welding with oxygen welding or argon arc welding good?

- Before welding need cleaning with acetone wire and base metal surface oil and oxide layer, according to welding tungsten diameter, filler wire diameter selection of appropriate welding parameters (base current, peak current, pulse width, pulse duration, pulse frequency, duty ratio, etc.).Oxygen acetylene (or oxygen propane) flame welding, flame welding due to large heating area, directly lead to weld coarse grains, degree of weld oxidation is lower than that of AC TIG welding effect. The weld strength and mechanical properties are lower.

- Q: This question asks for methods to determine if a building is utilizing high-quality aluminum sheets.

- <p>To determine if a building is using high-quality aluminum sheets, look for the following characteristics: the sheets should have a uniform and smooth surface without visible defects or impurities. Check for a strong and consistent thickness throughout the material. High-quality aluminum is also resistant to corrosion and should not show signs of rust or pitting. Additionally, the sheets should be lightweight yet rigid, indicating a high strength-to-weight ratio. You can also inquire about the manufacturer's specifications and certifications, as reputable suppliers will provide detailed information about the quality and composition of their aluminum sheets.</p>

- Q: Can aluminum sheets be used for electrical applications?

- Indeed, aluminum sheets find utility in electrical applications. Renowned for its exceptional conductivity, aluminum boasts nearly 60% of copper's electrical conductivity. This renders it suitable for diverse electrical applications, ranging from wiring and bus bars to transformers and electrical panels. Owing to their lightweight and resistance to corrosion, aluminum sheets are frequently employed in the fabrication of electrical enclosures and housings. Furthermore, aluminum emerges as a cost-effective alternative to other metals, such as copper, thereby solidifying its reputation as a favored selection in numerous electrical applications.

- Q: What specific requirements or considerations are necessary when using aluminum sheets in marine environments?

- <p>In marine environments, aluminum sheets must meet specific requirements to ensure durability and resistance to corrosion. These include using high-grade aluminum alloys, such as 5083 or 5086, known for their excellent resistance to saltwater corrosion. Protective coatings like anodizing or applying marine-grade paints can further enhance corrosion resistance. Additionally, the aluminum sheets should be designed to withstand the harsh conditions of marine environments, including high humidity, UV radiation, and mechanical stress. Regular maintenance and inspection are also crucial to prevent corrosion and ensure the longevity of aluminum structures in marine settings.</p>

- Q: Can aluminum sheets be reused or recycled after their initial use?

- <p>Yes, aluminum sheets can be recycled again after use. Aluminum is one of the most recycled materials globally due to its low cost of recycling and its ability to retain its properties even after multiple recycling processes. Recycling aluminum saves energy compared to producing new aluminum from raw materials, and it helps reduce waste in landfills.</p>

- Q: What advantages does the ceramic panel curtain wall have compared with the aluminum sheet and stone curtain wall?

- Now, there are many kinds of ceramic curtain walls. They are made of natural clay materials. They are green, environmentally friendly, low energy consumption, and they are not easy to fade and deform. They have good corrosion resistance and durability, and high strength. At present, the domestic market of ceramic tile is faster than that of foreign countries. I heard ruigao is the first manufacturer of ceramic plate, there are other TOB ah, new Kerry ah. The strength is good.

- Q: What is the price range of 101 aluminum sheets?

- The price range of 101 aluminum sheets can vary depending on various factors such as the thickness, size, and quality of the sheets. On average, the price range for 101 aluminum sheets can range from $50 to $150 per sheet. However, it is important to note that prices may vary among different suppliers and retailers. It is recommended to compare prices from multiple sources to get the best deal.

- Q: Can aluminum sheets be used for decorative wall panels?

- Yes, aluminum sheets can be used for decorative wall panels. Aluminum is a versatile material that offers a wide range of design options for wall panels. It is lightweight, durable, and resistant to corrosion, making it suitable for both interior and exterior applications. Aluminum sheets can be easily cut, formed, and fabricated into various shapes, patterns, and finishes, allowing for endless design possibilities. Additionally, aluminum can be powder-coated or anodized to enhance its appearance and provide additional protection against wear and tear. Whether it's for residential or commercial spaces, aluminum sheets can add a modern and stylish touch to any wall, making them a popular choice for decorative wall panels.

- Q: Can aluminum sheets be used for heat exchanger fins?

- Yes, aluminum sheets can be used for heat exchanger fins. Aluminum is a commonly used material for heat exchanger fins due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion.

Send your message to us

Aluminum Alloy Sheet for Construction and Semi Trailer Wall Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords