Aluminum 711 Sheets Food Grade Aluminum Slab with Lower Price in Our Warehouse

- Loading Port:

- Shanghai

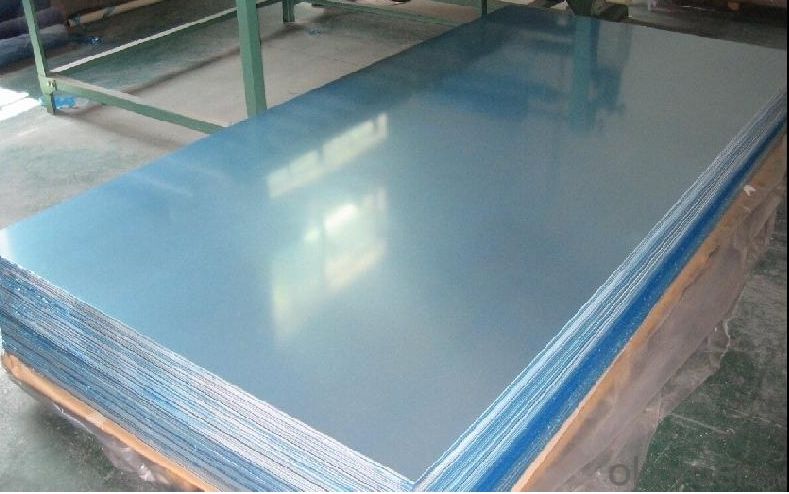

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

CNB, INTERNATIONAL CORPORATION'S Aluminum sheet is widely used in the field of industrial construction field, ETC. we also have cold rolled aluminum coil, checkered aluinium sheet, mirror finish aluminium coil,etc.

There are many different alloy nubmer: 3000SERIES,8000 series, etc. The detailed grade are as follows: 1010,1100, 2024, 3003, 5052,5754, 7075, 6063,8011, etc. The temper ARE AS FOLLOWS:H14, H24, F ,O, H1111,H114,etc.

2. Main features of the product

a. best-discount and the very competitiver price.

b. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1219mm*2438mm,500MM*500MM,1000*1000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 50mm to 2500mm, etc.

What is the length range:

---It is from 100mm to 6000mm, etc.

---Normally it is around 14 tons/each size.

How many tons did you export in one year?

Where is your client from?

---Normally it Arabia, BANGLADESH,PAKISTAN,FIJI, England,Turkey,etc.

What is your mainly products?

---Normally they are aluminum sheet,big-5-bar aluminium checkered sheet,small-,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Is it possible to recycle aluminum sheets multiple times?

- <p>Yes, aluminum sheets can be recycled again and again. The recycling process for aluminum is highly efficient, and it can be recycled indefinitely without losing any quality. This is due to the fact that aluminum retains its properties even after multiple recycling cycles. Each time aluminum is recycled, it can be melted down and reformed into new products, making it a sustainable and environmentally friendly material.</p>

- Q: How do you prevent galvanic corrosion when using aluminum sheets with saltwater?

- To avoid galvanic corrosion when utilizing aluminum sheets in saltwater, there exist several steps that can be taken: 1. The application of protective coatings is one effective method. This can be accomplished by employing specialized marine-grade paints or coatings specifically designed to hinder corrosion in saltwater environments. These coatings act as a barrier between the aluminum and the saltwater, effectively reducing the probability of galvanic corrosion. 2. Another approach involves the utilization of isolation materials, such as rubber or plastic gaskets, between the aluminum sheets and any dissimilar metals that may come into contact with them. These materials prevent direct contact between the aluminum and other metals, thereby minimizing the risk of galvanic corrosion. 3. Galvanic corrosion inhibitors can be added to the saltwater to help mitigate the risk of corrosion. These inhibitors function by creating a protective layer on the aluminum surface, thereby preventing the electrochemical reactions that lead to galvanic corrosion. 4. The implementation of cathodic protection techniques can also assist in preventing galvanic corrosion. This entails connecting the aluminum sheets to a sacrificial anode made from a more active metal, such as zinc or magnesium. The sacrificial anode corrodes instead of the aluminum, thus safeguarding it from galvanic corrosion. 5. Proper maintenance is crucial in preventing galvanic corrosion. Regularly cleaning and maintaining the aluminum sheets is essential, as saltwater and other contaminants can accumulate on the surface, promoting corrosion. Cleaning the sheets with fresh water and eliminating any salt deposits can help prolong their lifespan and reduce the risk of galvanic corrosion. It should be noted that these preventive measures should be implemented alongside proper material selection and design considerations. Seeking guidance from corrosion experts or engineers specializing in marine applications can provide further insight into the specific requirements and best practices for preventing galvanic corrosion when using aluminum sheets in saltwater.

- Q: Is it possible to utilize aluminum sheets in the interior design of vehicles?

- <p>Yes, aluminum sheets can be used for car interiors. They are lightweight, durable, and resistant to corrosion, making them suitable for various interior applications such as door panels, dashboards, and trim. Aluminum's malleability allows for easy shaping into complex designs, and it can be finished in various ways to match the aesthetic of the vehicle's interior. Additionally, its strength-to-weight ratio contributes to fuel efficiency and performance. However, it's important to consider the specific alloy and treatment of the aluminum to ensure it meets safety and comfort standards.</p>

- Q: Can the aluminum sheets be used for manufacturing chemical storage tanks?

- Yes, aluminum sheets can be used for manufacturing chemical storage tanks. Aluminum is a versatile material that offers several advantages for this purpose. It is lightweight, corrosion-resistant, and has high strength-to-weight ratio. These properties make it suitable for storing various chemicals safely. Additionally, aluminum can be easily formed into different shapes and sizes, allowing for customization of storage tanks to meet specific requirements. However, it is important to consider the type and concentration of chemicals being stored, as some chemicals may react with aluminum. In such cases, appropriate coatings or linings may be necessary to prevent any chemical reactions.

- Q: What are the weight considerations when using aluminum sheets?

- When using aluminum sheets, weight considerations are important due to the lightness of aluminum. It is crucial to determine the thickness and size of the sheet based on the intended application to ensure structural integrity and proper load-bearing capacity. Additionally, the weight of aluminum sheets may affect transportation, installation, and overall handling requirements.

- Q: is aluminum foil spacer poisonous after heating?

- It’s a kind of thermoprint material made by pressing the aluminum into sheet, and owing to its similar thermoprint effect to silver foil, so it’s called fake silver foil. Aluminum has soft texture, good ductility, and is silver white, if we use sodium silicate to paste the sheet after pressing on the offset paper, making aluminum foil, the foil can be printed. But aluminum foil is easy to be oxidized and darkens, rubbing and touching will make it darken, so it doesn’t suit for the thermoprint of books’ cover that needs to be preserved for a long time.

- Q: How do you join two aluminum sheets together?

- There are several methods to join two aluminum sheets together. One common technique is using mechanical fasteners such as screws, rivets, or bolts. These fasteners can be drilled or punched through the sheets, creating a secure connection. Another method is using adhesives specifically designed for aluminum bonding. These adhesives provide a strong and durable bond between the two sheets. Welding is another popular option, where the aluminum sheets are melted and fused together using heat. This method requires specialized equipment and expertise. Lastly, a technique called clinching can be used, which involves applying pressure to deform the aluminum sheets and interlock them together. Each method has its own advantages and considerations, depending on the specific application and desired outcome.

- Q: Can aluminum sheets be used for honeycomb panels?

- Indeed, honeycomb panels can indeed utilize aluminum sheets. To create honeycomb panels, it is customary to bond two slender sheets of material, like aluminum, to a core material in a honeycomb formation. Aluminum sheets are frequently employed in this process due to their advantageous traits of being lightweight and possessing high strength, rendering them an optimal selection for constructing honeycomb panels. The honeycomb structure itself results in a superior strength-to-weight ratio, rendering the panels suitable for an array of applications, encompassing aerospace, automotive, construction, and furniture industries. In addition to this, the aluminum sheets offer desirable attributes such as durability, resistance to corrosion, and ease of fabrication, thereby making them a widely favored option for honeycomb panels.

- Q: What is the corrosion resistance of aluminum sheets?

- Aluminum sheets possess remarkable resistance to corrosion. When exposed to oxygen, aluminum automatically develops a protective oxide layer on its surface, functioning as a barrier against corrosion. This layer is extremely stable and effectively halts any further oxidation of the metal, resulting in aluminum's exceptional resistance to corrosion in nearly all surroundings. Furthermore, aluminum sheets can be improved even further through surface treatments or coatings to augment their corrosion resistance. As a result, aluminum sheets are widely favored for a multitude of applications in which corrosion resistance is of utmost importance, including the construction industry, automotive manufacturing, and marine applications.

Send your message to us

Aluminum 711 Sheets Food Grade Aluminum Slab with Lower Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords