030 White Aluminum Sheets - China High Quality Roofing PE PVD Colour Coated Aluminium Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Packaging & Delivery

Packaging Details: | Standard export packing or following customer's demand |

Delivery Detail: | Within 20-25days or according to the order quantity |

High Quality and Factory Price Aluminum Coil

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

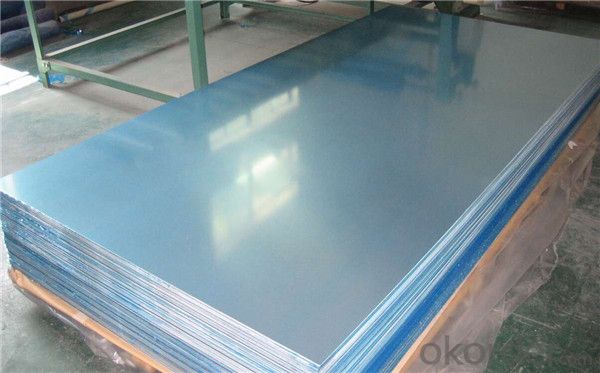

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

Parameter

Product | Alloy | Temper | Thickness | Width | I.D(mm) | Application |

Aluminum Coil/Strip | 1050,1060,1070, 1100,1200,1235, 1145,3003,304, 3105,3A21, 8011 | O H12 H14 H16 H18 H22 H24 H26 | 0.2-8mm | 50-2400mm | 75,150 200,300 400,505 (as customers's request) | construction,decoration, automobile,electronic, machinery,boat construction, aeronatics&astronautics, cookware,packing etc. |

Application:

1) Radiator

2) Condenser

3) Insulation Material

4) Construction

5) Decoration

6) Advertisement and market applications

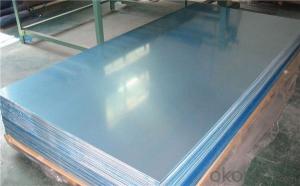

Photos

- Q: Are the aluminum sheets suitable for welding?

- Aluminum sheets can indeed be welded. Welding aluminum is a popular choice because of its lightweight nature, high strength-to-weight ratio, and resistance to corrosion. Nevertheless, it is crucial to acknowledge that welding aluminum necessitates specific techniques and considerations that differ from those used with other metals. Aluminum possesses a lower melting point and higher thermal conductivity, making it more challenging to weld when compared to steel or other metals. For this reason, specialized welding processes like Tungsten Inert Gas (TIG) welding or Metal Inert Gas (MIG) welding with a spool gun are frequently employed for aluminum welding. Moreover, proper cleaning and preparation of the aluminum surface, along with the utilization of appropriate filler materials, are essential for achieving strong and enduring welds. In conclusion, by utilizing the appropriate equipment, techniques, and expertise, it is possible to successfully weld aluminum sheets and create various structures and components.

- Q: we have the mass of an aluminum sample =.47g, and the number of atoms in sample =107

- Alright - first, find the number of moles of aluminium in that sample, by dividing the mass (0.47g) by the molecular weight of aluminium (26.98). Then, having obtained the number of moles, multiply it by the avogadro's constant (6.023x1023) and you will obtain the number of atoms, and by dividing the mass by the number of atoms, you get the mass of an individual atom.

- Q: What are the advantages of using aluminum sheets in the transportation industry?

- There are several advantages of using aluminum sheets in the transportation industry. Firstly, aluminum sheets are lightweight, which helps to reduce the overall weight of vehicles, resulting in improved fuel efficiency and reduced carbon emissions. Secondly, aluminum sheets offer excellent corrosion resistance, ensuring durability and longevity, even in harsh environments. Additionally, aluminum is highly malleable and can be easily formed into various shapes, enabling design flexibility and customization. Moreover, aluminum sheets have high strength-to-weight ratio, providing structural integrity and safety. Finally, aluminum is a recyclable material, making it a sustainable choice for the transportation industry.

- Q: Can aluminum sheets be used for HVAC systems?

- Certainly, HVAC systems can utilize aluminum sheets. Aluminum proves to be a favored material for HVAC applications owing to its numerous beneficial characteristics. Its lightweight nature facilitates effortless handling and installation. Moreover, aluminum exhibits remarkable resistance to corrosion, a vital attribute for HVAC systems subject to moisture and fluctuating temperatures. Additionally, aluminum boasts exceptional thermal conductivity, ensuring efficient heat transfer. Consequently, it becomes ideal for heat exchangers and other HVAC system components. In summary, aluminum sheets emerge as a dependable and long-lasting choice for HVAC systems.

- Q: What are the necessary safety measures to be aware of when handling aluminum sheets?

- <p>When working with aluminum sheets, it's crucial to wear appropriate personal protective equipment (PPE), including gloves to prevent cuts and eye protection to shield against flying debris. Ensure good ventilation to avoid inhaling dust or fumes from cutting or polishing. Use sharp tools to minimize the risk of accidents and always cut away from your body. Keep the work area clean and free of clutter to prevent slips or trips. Be cautious of electrical hazards if using power tools, and ensure all tools are properly grounded. Finally, be aware of the fire hazard potential of aluminum dust and store it safely away from ignition sources.</p>

- Q: Can aluminum sheets be anodized with custom colors?

- Yes, aluminum sheets can be anodized with custom colors. Anodizing is an electrochemical process that adds a protective oxide layer to the surface of aluminum, enhancing its durability and corrosion resistance. During the anodizing process, the aluminum sheet is immersed in an electrolytic solution and an electrical current is passed through it. This causes a controlled oxidation of the aluminum surface, creating a porous layer that can be dyed to achieve custom colors. By carefully selecting the dye, different shades and hues can be achieved, allowing for a wide range of custom color options. Additionally, anodized aluminum sheets can also be further processed with techniques such as laser engraving or printing to create unique designs and patterns, making them a versatile choice for various applications in industries like architecture, automotive, and electronics.

- Q: The user is asking if aluminum sheets can be used as a substitute for metal siding in construction.

- <p>Yes, aluminum sheets can be used to replace metal siding. They are lightweight, durable, and resistant to corrosion, making them a popular choice for siding. Aluminum sheets can be painted or finished to match various architectural styles and are low maintenance. However, it's important to ensure that the aluminum sheets are of the appropriate gauge and quality for the application, and that they are installed correctly to ensure longevity and performance.</p>

- Q: what is better for my 96 mustang gt. porting and polishing my stock heads or getting aluminum heads. also could i do a 3v conversion?

- Aluminum. They reduce weight and reduce heat!

- Q: Are aluminum sheets suitable for chemical filtration applications?

- Aluminum sheets prove to be a fitting option for chemical filtration applications. Renowned for its outstanding corrosion resistance and durability, aluminum emerges as a trustworthy selection for chemical filtration systems. It diligently sieves out impurities and contaminants across diverse chemical procedures, encompassing the separation of solids from liquids and the elimination of hazardous substances. Furthermore, aluminum sheets boast resilience against elevated temperatures and pressures, rendering them well-suited for an extensive array of chemical filtration applications.

- Q: Are aluminum sheets suitable for use in HVAC (heating, ventilation, and air conditioning) systems?

- Yes, aluminum sheets are suitable for use in HVAC systems. They offer several advantages such as high thermal conductivity, corrosion resistance, and lightweight nature, making them ideal for efficient heat transfer and durability in HVAC applications.

Send your message to us

030 White Aluminum Sheets - China High Quality Roofing PE PVD Colour Coated Aluminium Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords