Aluminum Flat Sheets for Sale - Aluminium Sheet 1050 H32 Mill Finish with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.specification

material: | Alloy or not | ||

thickness: | 1,3 series | 0.3-9.5mm | |

5series | 0.5-150mm | ||

6 series | 5-150mm | ||

7series | More than 6mm | ||

width: | 1,3 series | 900-1500mm | |

5 series | 900-1500mm | ||

6 ,7series | As your request | ||

Circulation size: (width*length)

| 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm | ||

Usage : | Boat, plane, building, packaging, machine…. | ||

MOQ | 3 tons | ||

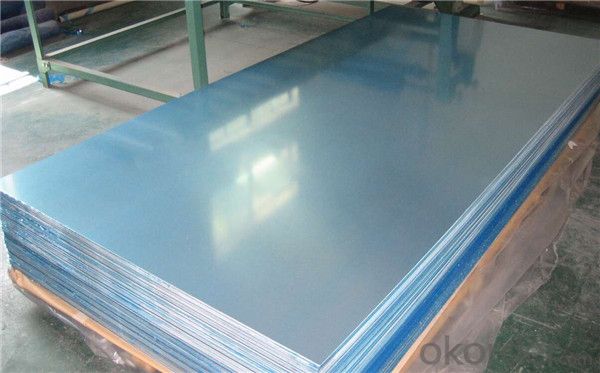

2.product show

Dear Customer, why do I have the confidence to let you buy our product ?

♥strict chemical composition , good hardness high safety performance

♥Oxide film thickness, corrosion resistance

♥Standard aluminum closed time, no rust

♥smooth surface, no burrs

Our VS others

3.shipping:

20~25 working days & send samples:2--3 days after received your advance payment

Mode of transport | advantage | disadvantage | advice |

Express delivery | Fast(3—6days ),door to door wide area coverage | Volume & weight restricted | Good for small cargo |

Sea transpoet | Cheapest volume unlimited | Long sailing time influenced by climate and port conditions | Bulk cargo loose time |

Air transport | Fast(4—5days) simple packaging | The most expensive volume restrict | For valuable cargo urgent need |

Railway | Big volume more expensive | Tracking difficult transit organization may cause delay | Preferred in central Asia |

4.Product photos

- Q: Can aluminum sheets be used for packaging purposes?

- Yes, aluminum sheets can be used for packaging purposes. Aluminum is a versatile and popular material for packaging due to its excellent barrier properties, durability, and light weight. It is commonly used in various forms such as aluminum foil, cans, and containers for packaging a wide range of products including food, beverages, pharmaceuticals, and cosmetics. Aluminum sheets offer several advantages for packaging purposes, including resistance to moisture, oxygen, light, and bacteria, which helps to protect the contents and maintain their freshness. Additionally, aluminum sheets can be easily shaped, molded, or folded to create different packaging designs, making it a preferred choice for many packaging applications.

- Q: Are aluminum sheets affected by UV radiation or sunlight exposure?

- Yes, aluminum sheets are generally not affected by UV radiation or sunlight exposure. Aluminum is known for its excellent resistance to corrosion and weathering, including the harmful effects of UV radiation. Therefore, aluminum sheets remain durable and retain their physical properties even when exposed to sunlight for extended periods.

- Q: This question asks if there are any potential risks or hazards associated with using windows that are manufactured from recycled materials.

- <p>There are generally no significant safety concerns with using windows made from recycled materials. These windows are often made from recycled plastics or glass, which are processed to ensure they meet safety and quality standards. However, it's important to ensure that the recycled materials used are free from contaminants and are processed correctly to maintain structural integrity. Additionally, the manufacturing process should adhere to environmental and safety regulations to prevent any health or environmental risks. Always check for certifications and standards that the windows meet to ensure their safety and reliability.</p>

- Q: Can the aluminum sheets be used for manufacturing furniture?

- Yes, aluminum sheets can certainly be used for manufacturing furniture. Aluminum is a lightweight and strong material, making it ideal for creating furniture that is both durable and easy to move around. Additionally, aluminum is resistant to corrosion, so it can withstand exposure to various environmental conditions. Moreover, aluminum sheets can be easily shaped and formed into different designs, allowing for versatility in furniture manufacturing. Overall, using aluminum sheets for furniture manufacturing can result in high-quality, stylish, and long-lasting pieces.

- Q: I know that aluminum doesn't belong in the human body. As a canister to hold liquids which will be consumed later, is aluminum good or bad to use?

- I okorder /

- Q: Would you please tell me what putty to use on the aluminium board, what kind of putty, and the painting process?

- You can also consider adding primer or putty, and then spray paint.In summary, adhesion of the topcoat is reinforced with an agent.

- Q: Can aluminum sheets be easily bent or shaped?

- Yes, aluminum sheets can be easily bent or shaped due to their malleability, making them ideal for various applications in industries such as construction, automotive, and aerospace.

- Q: Trying to find the best aluminum powder I can buy for rocket engines and pyrotechnic (fireworks) uses?

- It really depends on your formula and how the aluminum is being used in the formula. Is it a part of the fuel or is an additive to the fuel for sparks?

- Q: Can the aluminum sheets be used for manufacturing heat exchanger fins?

- Yes, aluminum sheets can be used for manufacturing heat exchanger fins.

- Q: What is the electrical resistivity of 101 aluminum sheets?

- The electrical resistivity of 101 aluminum sheets would depend on multiple factors, such as the thickness, purity, and temperature of the sheets. Without specific information about these factors, it is not possible to provide a precise answer.

Send your message to us

Aluminum Flat Sheets for Sale - Aluminium Sheet 1050 H32 Mill Finish with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords