Diamond Plate Aluminum Sheets - Aluminium Profiles Thermal Barrier SAD601

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Profiles Thermal Barrier SAD601 Description:

Aluminium Profiles Thermal Barrier SAD601(also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profiles Thermal Barrier SAD601:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

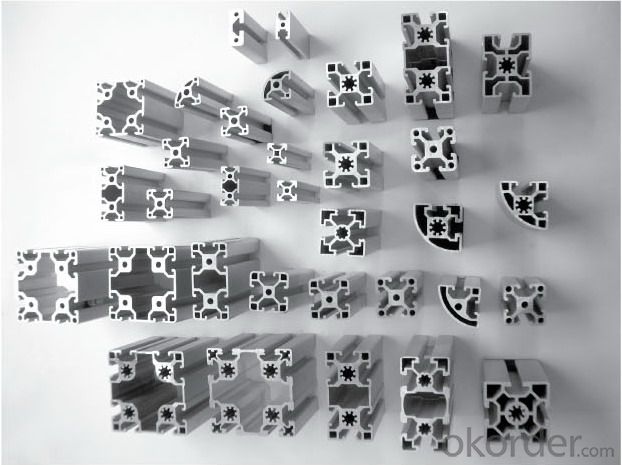

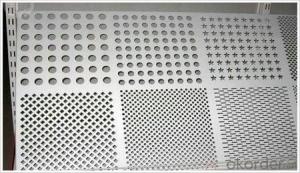

3.Aluminium Profiles Thermal Barrier SAD601 Images:

4.Aluminium Profiles Thermal Barrier SAD601 Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can aluminum sheets be used for furniture manufacturing?

- Certainly! Furniture manufacturing can make use of aluminum sheets. Aluminum is a highly versatile material that possesses several advantageous properties, making it suitable for the production of furniture. Lightweight, durable, and corrosion-resistant, aluminum can be easily shaped into various sizes and forms. Additionally, aluminum has a sleek and modern appearance, making it a popular choice for contemporary furniture designs. Frames, legs, and other structural components for chairs, tables, shelves, and cabinets can be fashioned from aluminum sheets. The versatility and durability of aluminum make it a viable option for furniture manufacturing, particularly for outdoor or industrial furniture that requires resistance to harsh weather conditions or heavy use.

- Q: Are the aluminum sheets suitable for aerospace applications?

- Yes, aluminum sheets are suitable for aerospace applications due to their lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance, making them ideal for aircraft structures and components. Moreover, aluminum's ability to be easily machined, formed, and welded further enhances its suitability for aerospace use.

- Q: The which temperature the aluminum evaporates in vacuum?

- Aluminum boils at 2519 °C (4566 °F) at normal pressure. In a vacuum, it might boil (a little) at 808 °C, but actually this is better known as subliming.

- Q: For a high school Chemistry course I made soap for a project. Before doing this, thank god, i learned that one should never use an aluminum container to mix the lye (NaOH) and water. Now, I need to know why. I know it eats away at the container but i can't figure out why. It goes against everything I've learned so far. At first i thought it was because Aluminum was, for some strange reason :o, more reactive than Sodium therefore replacing it in the reaction but that turned out not to be true. Does anyone have an idea of why? Thanks

- Under normal circumstances, aluminum does not react with water, as an impermeable protective layer composed of aluminum hydroxide either forms within seconds or is already in place. With the addition of sodium hydroxide, the formation of a protective layer is prevented. With the production of aluminates [ Al(OH)4 ]-, the amphoteric (capable of acting as either an acid or a base) aluminum hydroxide Al(OH)3 goes in solution: 2 Al + 6 H2O -- 2 Al(OH)3 + 3 H2 Al(OH)3 + NaOH -- Na+ + [ Al(OH)4 ]- A layer of aluminum oxide previously formed by passive corrosion is dissolved by the addition of sodium hydroxide. For this reason, the reaction takes place at the beginning relatively slowly: Al2O3 + 2 NaOH + 3 H2O -- 2 Na+ + 2 [ Al(OH)4 ]- The aluminum completely dissolves and the water acts here too as an acid (for an analog, see Experiment 4.4.1). This reaction is used in drain cleaners. They are mostly made out of strong alkalis, to which alumunim or zinc has been added. The alkalis break down organic residues chemically. In addition, the formation of hydrogen leads to a bubbling effect which adds an additional mechanical cleaning mechanism. The big problem here is the formation of hydrogen gas (as well as some heat). The hydrogen gas is flammable, and if it's in a closed container, will explode

- Q: Are aluminum sheets resistant to rust?

- Indeed, the resistance of aluminum sheets to rust is remarkably high. This is due to the natural formation of a protective oxide layer on the surface of aluminum when it comes into contact with air, thereby hindering further corrosion. In contrast to iron or steel that can rust in the presence of moisture and oxygen, aluminum does not necessitate any supplementary coatings or treatments to safeguard against rust formation. Consequently, aluminum sheets are widely favored across various sectors such as construction, automotive, and marine industries, where the prevention of rust is imperative.

- Q: which has more volume? a kg of gold or a kg of aluminum? please explain in physics terms

- Gold is a heavy metal and aluminum is very light. So aluminum would take up lots more space than an equal weight of gold, even if the aluminum was forged into a smaller size.

- Q: a 1 kg block of aluminum and a 1 kg block of lead are immersed in water, Both sink, but which experienced the greater buoyant force? Why?

- Buoyant force = weight of water displaced The thing that affects the weight displaced is the volume of the metal blocks. Both Aluminum and Lead have the same mass (1kg) but Lead is more dense than Aluminum (11.34g/cm^3 vs 2.70g/cm^3). As such, the 1kg of Aluminum has a greater volume than Lead and hence experienced the greater buoyant force.

- Q: Can aluminum sheets be embossed?

- Indeed, it is possible to emboss aluminum sheets. The act of embossing entails producing a design that is elevated or inset on the surface of a material. Aluminum is a versatile substance that can be easily manipulated, including being subjected to embossing. One can employ different techniques in order to emboss aluminum sheets, such as heat embossing or using tools and machines specifically designed for embossing. By undergoing the embossing process, the aluminum sheets gain texture and depth, resulting in an enhanced appearance suitable for a wide range of applications. These applications may include decorative purposes, signage, nameplates, and even the addition of texture to automotive or architectural accents.

- Q: Can aluminum sheets be used for missile components?

- Indeed, missile components can indeed be made from aluminum sheets. Aluminum, an adaptable and light substance, boasts remarkable strength-to-weight ratio properties. These attributes render it a fitting option for a range of aerospace uses, including missile components. Aluminum sheets present benefits like resistance to corrosion, excellent thermal conductivity, and simplicity in fabrication. Moreover, aluminum exhibits the ability to endure extreme temperatures, making it a suitable choice for missile components that might encounter intense heat during flight. Nevertheless, it is crucial to take into account the specific requirements of the missile system and seek guidance from authorities in the field to ensure that aluminum sheets are suitable for the intended purpose.

- Q: Can aluminum sheet be bent or formed into different shapes?

- Yes, aluminum sheet can be easily bent or formed into different shapes. Aluminum is a highly malleable metal, which means it can be easily bent, shaped, or formed without cracking or breaking. This property makes it an ideal choice for various applications where flexibility and customization are required. Aluminum sheets can be bent using various methods, such as using a brake press, roll forming, or by hand using specialized bending tools. The level of bendability may vary depending on the thickness and grade of the aluminum sheet, but in general, aluminum is known for its excellent formability and ability to be shaped into different configurations.

Send your message to us

Diamond Plate Aluminum Sheets - Aluminium Profiles Thermal Barrier SAD601

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords