024 96 Wide Aluminum Sheet Coil Houston - Aluminium Prepainted Coil Hot Demanded 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Prepainted Coil Hot Demanded 3003:

Aluminium coil/sheet are of a wide range of specifications, and they are widely used in:Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...Advertisement: display platforms, signboards, fascia, shop fronts...

Main Features of Aluminium Prepainted Coil Demanded 3003 :

1) High gloss

2) High flexibility

3) Impact resistance

4) Excellent weather-proof durability

5) Anti-ultraviolet

6) High erosion resistance

7) Stable color and gloss

8) Good mechanical processing performance

9) Abrasion resistance

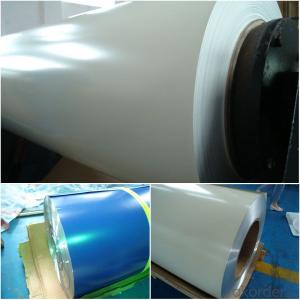

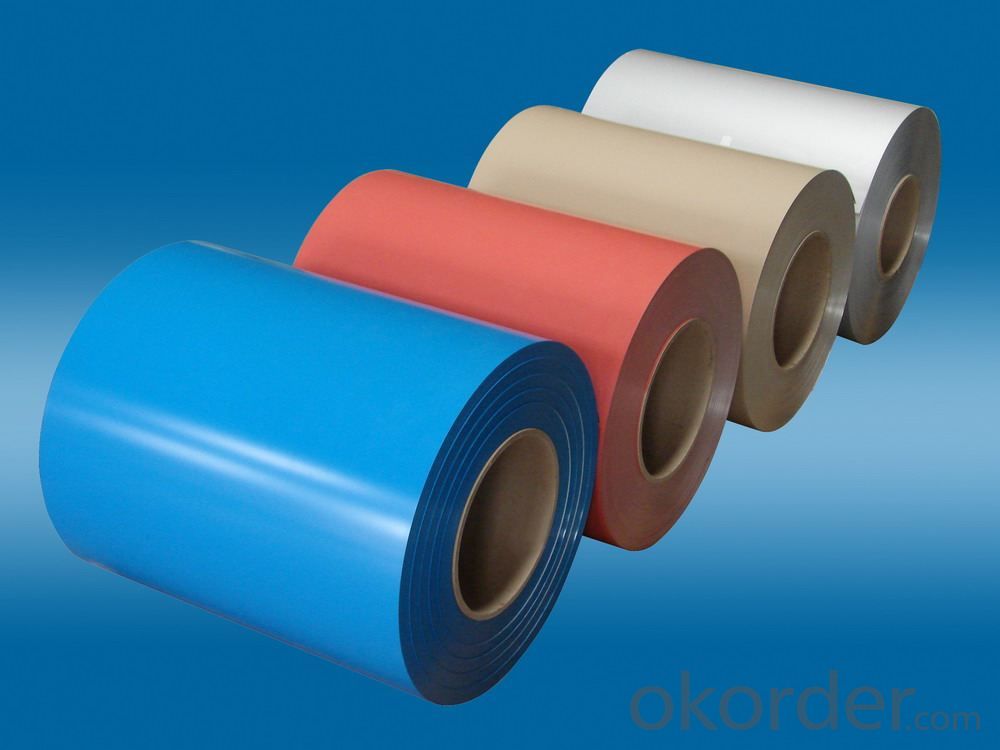

Image of Aluminium Prepainted Coil Demanded 3003:

Specifications of Aluminium Prepainted Coil Demanded 3003:

Alloy | A1100,A3003, A8011 etc |

Temper | H16,H18,H26 |

Thickness | 0.02-3.0mm |

Width | Standard width:1200 1240mm |

30mm-1500mm | |

Diameter | Outside dia:1200mm\1000mm\1240 |

Interior dia: 405mm,505mm | |

Weight | 1.5T/coil,2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, |

Surface | Color coated, Embossed, mill finish, |

Color | As to RAL |

Gloss | 10 - 90%(EN ISO-2813:1994) |

Coating Thickness | P E : more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ of Aluminium Coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum coils be used in electrical applications?

- Yes, aluminum coils can be used in electrical applications. Aluminum is often used as a conductor in electrical wiring due to its high conductivity and low cost compared to copper. Aluminum coils are commonly used in transformers, motors, generators, and other electrical equipment. However, it is important to note that aluminum has a lower electrical conductivity than copper, so larger aluminum coils may be required to achieve the same level of conductivity. Additionally, aluminum coils may require special insulation and connectors to prevent corrosion and ensure proper electrical connections.

- Q: This question asks for a comparison between cold rolling and hot rolling processes, specifically in the context of steel wire production for coilings.

- <p>Cold rolling and hot rolling are two distinct processes used in the manufacturing of steel wires for coilings. Hot rolling is performed at high temperatures, typically above the recrystallization temperature of the steel, which allows the material to be shaped more easily. This process results in a more ductile and less hard steel, which can be beneficial for certain applications. However, hot-rolled steel may have a rougher surface and may require further processing to achieve desired dimensions and surface finish. Cold rolling, on the other hand, is done at room temperature, which imparts a harder and smoother surface to the steel. It is more precise and results in tighter tolerances, making it suitable for applications requiring high strength and precision. Cold-rolled steel also has better surface finish and dimensional accuracy compared to hot-rolled steel. However, cold rolling is more energy-intensive and may not be suitable for very thick materials due to the increased hardness of the steel at room temperature.</p>

- Q: What are the different types of end conditions for aluminum coils?

- The different types of end conditions for aluminum coils include plain end, slit end, trimmed end, and sheared end.

- Q: How are aluminum coils protected against scratching and abrasion?

- Aluminum coils are typically protected against scratching and abrasion through various methods, such as applying a protective coating or film. This coating acts as a barrier, shielding the surface of the coils from potential damage during handling, transportation, and processing. Additionally, some manufacturers may use protective packaging materials, such as plastic or cardboard, to further safeguard the coils against scratching and abrasion.

- Q: This question asks for a comparison of various types of equipment used for welding aluminum coils, highlighting their distinct features and applications.

- <p>Aluminum coil welding equipment varies based on technology, power source, and application. TIG (Tungsten Inert Gas) welders are known for high-quality welds and are ideal for thin aluminum coils. MIG (Metal Inert Gas) welders are versatile and suitable for thicker coils, offering faster welding speeds. Stick welders are more portable and cost-effective but produce lower quality welds. Laser welders provide precise, deep penetration welds suitable for high-precision applications. Friction stir welding is a solid-state process that offers excellent joint properties without melting the metal. Each type has its advantages and is chosen based on the specific requirements of the welding task, such as material thickness, weld quality, and production rate.</p>

- Q: How do aluminum coils compare to other metals in terms of strength?

- Aluminum coils have excellent strength-to-weight ratio compared to many other metals. While aluminum is not as strong as steel, it is lighter and more flexible, making it a popular choice in various applications. Aluminum coils can withstand significant forces without breaking or deforming, making them suitable for a wide range of industries, including automotive, aerospace, and construction. Additionally, aluminum coils have good corrosion resistance, which further enhances their durability and longevity. However, it is important to note that the strength of aluminum can vary depending on the alloy and temper used, so specific comparisons should be made based on the particular application and requirements.

- Q: What are the dimensions of an aluminum coil?

- The dimensions of an aluminum coil can vary depending on its intended use and manufacturing specifications. However, typical dimensions for an aluminum coil range from 0.2mm to 8mm in thickness and 200mm to 2000mm in width. The length of an aluminum coil can vary and is often determined by the customer's specific requirements. Additionally, the weight of an aluminum coil can vary depending on its thickness and dimensions.

- Q: This question asks about the duration an aluminum coil can last before it needs to be replaced or becomes unusable.

- <p>The lifespan of an aluminum coil can vary significantly depending on its application, quality of the material, and environmental conditions. Generally, if properly stored and used, aluminum coils can last for several years without significant degradation. However, in industrial settings where coils are subjected to continuous use and harsh conditions, their lifespan might be reduced to a few years or even less. Regular maintenance and inspection can help extend the lifespan of aluminum coils.</p>

- Q: The user is asking if it's possible to use an electric welder for joining aluminum coils.

- <p>Yes, you can use an electric welder to weld aluminum coils together. However, it's important to use the correct type of welder and settings. Gas tungsten arc welding (GTAW), also known as TIG welding, is commonly used for aluminum due to its precision and ability to control heat input. MIG (Metal Inert Gas) welding can also be used for thicker aluminum materials. Ensure you use the right filler material, a suitable welding current, and proper shielding gas to prevent oxidation. Always follow safety precautions and consult with a professional if you're unsure about the welding process.</p>

- Q: I want to know when it comes to racing which is better? I have a 24 inch aluminium bmx frame and want to know if chromoly frames are faster? Also before buying parts for my bike should I go all aluminum like the bars and forks? Also which is faster the aluminum or the chromoly frame?

- problematic problem. research in yahoo. this will help!

Send your message to us

024 96 Wide Aluminum Sheet Coil Houston - Aluminium Prepainted Coil Hot Demanded 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords