High Quality Coil Aluminum Stock - Aluminium Pre-Painted Coil/Sheet Serie 3

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

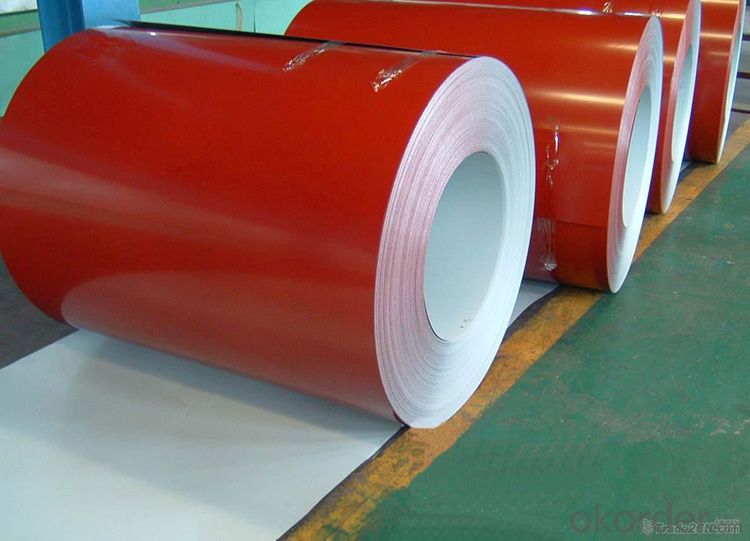

Structure of Aluminium Aluminium Pre-painted Coil/Sheet Serie 3 High Qulity Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Pre-painted Coil/Sheet Serie 3 High Qulity:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of theAluminium Pre-painted Coil/Sheet Serie 3 High Qulity:

Aluminium Pre-painted Coil/Sheet Serie 3 High Qulity Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Pre-painted Coil/Sheet Serie 3 High Qulity:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Are aluminum coils suitable for manufacturing cookware?

- Yes, aluminum coils are suitable for manufacturing cookware. Aluminum is a popular choice for cookware due to its excellent heat conductivity, which allows for even heating and efficient cooking. It also has a lightweight and durable nature, making it easy to handle and long-lasting. Additionally, aluminum is resistant to rust and corrosion, making it an ideal material for cookware that is frequently exposed to water and heat. However, it is important to note that uncoated aluminum cookware may react with certain acidic or alkaline foods, leading to a metallic taste. To overcome this, many aluminum cookware manufacturers use non-stick coatings or anodized finishes to prevent food reactions and improve the durability of the cookware. Overall, aluminum coils are a suitable material for manufacturing cookware, but it is essential to consider the specific requirements and coatings needed for different types of cookware to ensure safety and optimal performance.

- Q: Why does aluminum foil burn in the microwave but not in the oven?

- A microwave is so called because it runs on electromagnetic microwaves. Because it is magnetic, it clashes with the aluminum foil.

- Q: Is there any specific regulation or standard that dictates the weight of an aluminum coil?

- <p>Yes, there are regulations and standards that dictate the weight of aluminum coils. These are often set by industry standards such as ASTM (American Society for Testing and Materials) and EN (European Norm). The weight of an aluminum coil can vary depending on its thickness, width, and length, and manufacturers must adhere to these standards to ensure consistency and quality. For example, ASTM B 209 specifies the standard for aluminum and aluminum alloy sheet and plate, which includes weight limits. Compliance with these standards is crucial for the safety and performance of products that utilize aluminum coils.</p>

- Q: A nitrate is added with sodium hydroxide, then a piece of aluminum foil. After warming the mixture, ammonia gas is released.A source tells me that aluminum reduces nitrate ion into the ammonium ion. How is this done?

- Aluminum is an active metal and wants to be ionized. Al -- Al(3+) + 3e(-) ?n basic media, tetrahydroxoaluminate complex will be formed: Al(3+) + 4OH(-) -- Al(OH)4(-) ======================================... Al + 4OH(-) -- Al(OH)4(-) + 3e(-) Nitrate is reduced to ammonia in basic media, ammonium in acidic media: N(5+) + 8e(-) -- N(3-) NO3(-) + 8e(-) + 10H(+) -- NH4(+) + 3H2O in basic media, we add base (OH-) to both sides: NO3(-) + 8e(-) + 11OH(-) + 10H(+) -- NH4(+) + 3H2O + 11OH(-) NO3(-) + 8e(-) + OH(-) + 10H2O --- NH3 + 4H2O + 10OH(-) ======================================... NO3(-) + 8e(-)+ 6H2O -- NH3 + 9OH(-) Now, to the balancing of these two redox half reactions: Al + 4OH(-) -- Al(OH)4(-) + 3e(-) NO3(-) + 8e(-)+ 6H2O -- NH3 + 9OH(-) ============================= 8Al + 32OH(-) -- 8Al(OH)4(-) + 24e(-) 3NO3(-) + 24e(-) + 18H2O -- 3NH3 + 27OH(-) ================================== 8Al + 3NO3(-) + 32OH(-) + 18H2O -- 8Al(OH)4(-) + 3NH3 + 27OH(-) //////////////////////////////////////... 8Al + 3NO3(-) + 5OH(-) + 18H2O -- 8Al(OH)4(-) + 3NH3 Hope this helps.

- Q: Explain how aluminum coil interacts with magnetic fields and what effects can be observed.

- <p>Aluminum coil itself does not have a direct relationship with magnetic fields in terms of magnetic properties, as aluminum is not a magnetic material and does not get magnetized. However, when an aluminum coil is part of an electrical circuit, it can interact with magnetic fields in the context of electromagnetic induction. If a changing magnetic field passes through an aluminum coil, it can induce an electromotive force (EMF) or voltage in the coil, according to Faraday's law of electromagnetic induction. This induced voltage can cause an electric current to flow through the coil if it is part of a closed circuit. The aluminum coil's primary interaction with magnetic fields is thus through the generation of electrical current when used in conjunction with an electric circuit.</p>

- Q: This question asks for methods to determine whether an aluminum coil is safe for use.

- <p>To determine if your aluminum coil is safe to use, first, check for any visible signs of damage such as cracks, corrosion, or deformation. Ensure that the coil meets the required specifications for your application, including thickness, width, and alloy type. Verify the coil's compliance with safety standards and certifications relevant to your industry, such as ASTM or ISO standards. Test the coil's mechanical properties to ensure it has the necessary strength and ductility. Finally, consider the coil's history and usage; it should not have been exposed to extreme temperatures or corrosive environments that could compromise its integrity. Consulting with a materials expert or conducting a thorough inspection can provide further assurance of the coil's safety.</p>

- Q: Are aluminum coils available in custom sizes?

- Indeed, custom sizes for aluminum coils are readily obtainable. Aluminum coils exhibit great versatility and can be produced to satisfy particular size specifications. This adaptability enables their utilization in a diverse array of industries. Be it for HVAC systems, transportation, construction, or any other purpose, aluminum coils can be specifically tailored to suit the unique requirements of any given project. The provision of custom-sized aluminum coils guarantees an impeccable fit and outstanding performance, thereby promoting enhanced efficiency and cost-effectiveness.

- Q: Can aluminum coils be used in automotive applications?

- Yes, aluminum coils can be used in automotive applications. Aluminum is a lightweight and corrosion-resistant material, making it a suitable choice for various automotive components, including coils. Its high thermal conductivity also allows for efficient heat transfer, making it beneficial for applications such as radiators and air conditioning systems.

- Q: What are the different coil annealing options available for aluminum coils?

- There are several coil annealing options available for aluminum coils, depending on the desired outcome and requirements. 1. Full Annealing: This is a process where the aluminum coil is heated to a specific temperature and then slowly cooled down. Full annealing helps to relieve internal stresses, improve ductility, and enhance the mechanical properties of the coil. It also results in a soft and fully recrystallized structure. 2. Solution Annealing: Solution annealing is primarily used for heat-treatable aluminum alloys. It involves heating the coil to a temperature above the alloy's solvus temperature, followed by rapid cooling. This process helps dissolve and redistribute any alloying elements, resulting in a homogenous microstructure. 3. Stabilization Annealing: Stabilization annealing is performed on certain aluminum alloys to enhance their dimensional stability and reduce the risk of distortion during subsequent processing or usage. It involves heating the coil to a temperature just below the alloy's recrystallization temperature and then slowly cooling it. 4. Stress Relief Annealing: This type of annealing is performed to relieve residual stresses that may have developed during previous manufacturing processes, such as rolling or stretching. The coil is heated to a specific temperature and held there for a certain duration, allowing the stresses to relax. It helps to improve the coil's formability and minimize the risk of deformation during subsequent operations. 5. Intermediate Annealing: Intermediate annealing is performed during the manufacturing process to restore the ductility and formability of the aluminum coil. It involves heating the coil to a temperature below the recrystallization temperature, followed by a controlled cooling process. This helps to eliminate work hardening that may have occurred during previous operations. These are some of the common coil annealing options available for aluminum coils. The specific choice depends on factors such as the alloy composition, intended application, and desired material properties. It is important to consult with experts or heat treatment professionals to determine the most suitable annealing method for a particular aluminum coil.

- Q: What are the factors that determine the price of aluminum coils?

- The factors that determine the price of aluminum coils include the current market demand and supply, the cost of raw materials, production and manufacturing costs, transportation costs, market competition, and any additional factors such as tariffs or taxes.

Send your message to us

High Quality Coil Aluminum Stock - Aluminium Pre-Painted Coil/Sheet Serie 3

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords