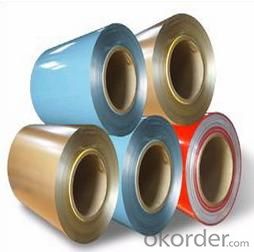

5083 Aluminum Coil for Sale - Pre-Painted Alu Foil in Different Colors

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 μm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

- Q: How do aluminum coils perform in extreme temperature conditions?

- Aluminum coils exhibit satisfactory performance in extreme temperature conditions. With a high melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit), aluminum is well-suited for handling high temperatures. Additionally, its exceptional thermal conductivity allows for efficient heat transfer and rapid cooling in extreme heat situations. This characteristic proves particularly advantageous in applications like air conditioning systems and refrigeration units, where aluminum coils are commonly utilized. Furthermore, aluminum is renowned for its corrosion resistance, a quality that is vital in extreme temperature settings. It resists oxidation and does not easily succumb to rust, ensuring the durability and longevity of the coils. This resistance to corrosion is especially significant in environments characterized by high humidity or exposure to salt, where alternative metals may rapidly corrode. Nevertheless, it is important to note that the performance of aluminum coils may be affected by extremely cold temperatures. In such conditions, aluminum contracts and becomes more brittle, potentially leading to reduced flexibility and even cracking. Consequently, it becomes crucial to provide proper insulation and protection to prevent any damage to the coils in extremely cold surroundings. Overall, aluminum coils can be relied upon and demonstrate commendable performance in extreme temperature conditions, particularly in applications involving high temperatures. Their high melting point, excellent thermal conductivity, and resistance to corrosion render them suitable for a wide range of industries and environments.

- Q: Can aluminum coils be used for electrical conductivity purposes?

- Using aluminum coils for electrical conductivity purposes is not possible. Although aluminum is a decent conductor of electricity, it is not appropriate for coils that are specifically intended for electrical conductivity. Aluminum has a higher resistance in comparison to materials like copper or silver, which are frequently used for electrical conductivity purposes. Furthermore, aluminum has a lower melting point than copper, therefore utilizing it in coils for high electrical currents can result in overheating problems. Consequently, it is more typical to use materials such as copper or silver for electrical conductivity purposes, particularly in situations where high conductivity and low resistance are necessary.

- Q: Can aluminum coils be used in aerospace heat exchangers?

- Aerospace heat exchangers can indeed utilize aluminum coils. In the aerospace industry, aluminum is widely employed due to its lightweight nature and exceptional thermal conductivity. Heat exchangers play a critical role in aerospace systems by transferring heat between different mediums. Aluminum coils effectively conduct heat, making them suitable for aerospace heat exchangers. Moreover, aluminum's resistance to corrosion is essential in the challenging environments encountered in aerospace applications. Additionally, its low density contributes to fuel efficiency by reducing the overall weight of aircraft. Hence, aerospace heat exchangers prefer aluminum coils owing to their outstanding thermal conductivity, lightweight properties, and corrosion resistance.

- Q: What are the common testing methods for aluminum coils?

- There are several common testing methods for aluminum coils that are used to ensure their quality and performance. These methods include: 1. Visual inspection: This involves a thorough examination of the coils for any visible defects such as dents, scratches, or surface irregularities. Visual inspection is a basic and initial step in the testing process. 2. Dimensional measurement: This method involves measuring the dimensions of the aluminum coils to ensure they meet the specified requirements. This includes measuring the length, width, and thickness of the coils. 3. Tensile testing: Tensile testing is performed to assess the mechanical properties of the aluminum coils, such as their strength and elasticity. This test involves applying a tensile force to a sample of the coil until it breaks or deforms, allowing for the determination of its tensile strength. 4. Hardness testing: The hardness of aluminum coils is an important factor in determining their suitability for specific applications. Various hardness testing methods, such as Rockwell or Brinell hardness tests, can be used to measure the resistance of the coil's surface to indentation or scratching. 5. Chemical composition analysis: This method involves analyzing the chemical composition of the aluminum coil to ensure it meets the required specifications. Common techniques used for this analysis include spectroscopy or X-ray fluorescence (XRF) analysis. 6. Corrosion resistance testing: Aluminum coils are often exposed to harsh environmental conditions, so assessing their resistance to corrosion is crucial. This can be done through various tests like salt spray testing or electrochemical impedance spectroscopy (EIS) to determine the coil's ability to withstand corrosion. 7. Coating quality assessment: If the aluminum coil is coated with a protective layer, testing methods such as adhesion testing, coating thickness measurement, or impact resistance testing can be used to ensure the quality and durability of the coating. These are some of the most common testing methods employed for aluminum coils. By conducting these tests, manufacturers can ensure that the coils meet the required standards and perform optimally in their intended applications.

- Q: How are aluminum coils measured and specified?

- Aluminum coils are typically measured and specified using two key parameters: thickness and width. The thickness of an aluminum coil refers to the thickness of the aluminum sheet used to make the coil, and it is commonly measured in millimeters (mm) or gauge. The width of a coil, on the other hand, refers to the width of the aluminum sheet that is wound into a coil shape and is usually measured in inches or millimeters. These measurements and specifications are crucial in determining the suitability of the coil for various applications and manufacturing processes.

- Q: Some makes like KIA make a point of having aluminum engines. I thought this was for weight, but was more prone to failure, especially in a high mileage car.

- aluminum is a very flexible and heat intolerant metal. It is used to save weight....period. Normal use is fine but more frequent cooling system maintenance is required. Never overheat an aluminum engine as you'll let the magic smoke out when it warps every piece in it

- Q: I want to know when it comes to racing which is better? I have a 24 inch aluminium bmx frame and want to know if chromoly frames are faster? Also before buying parts for my bike should I go all aluminum like the bars and forks? Also which is faster the aluminum or the chromoly frame?

- I'm not a racer, so don't quote me on anything. The metal doesn't make you faster. The difference between aluminum and chromoly is strength and weight. Aluminum is much weaker than chromoly, but also much lighter. I believe aluminum parts are generally used for racers under 110 lbs, but, again, I'm not a racer so I'm not exactly sure.

- Q: I was wandering, if your spear's shaft is made of aluminum, does that have any strength to it, i mean, say you had to block with the shaft, would a weapon break through like your basic sword or basic axe, i don't mean big heavy swords and axes, but like average ones, could it break through an aluminum shaft of a spear?

- From my understanding aluminum weapons are only for exhibitions and never for anything close to real, let alone impact. Aluminum can be a strong/durable metal, but in the end it can hardly hold up against wood like pine, let alone oak. There's also here-say about aluminum shattering. I don't really know what that's about, but I have heard a rumor that about some doing so, whatever the extend of shattering really means. I wouldn't bother with aluminum when there's very fine woods that can be used instead. Aluminum is also cheap and it's said you get what you pay for. Personally, I'd forget aluminum and go with a hard wood.

- Q: What is the typical conductivity of aluminum coils?

- Aluminum coils exhibit a relatively high typical conductivity, with a range of values between 34 and 38 million Siemens per meter (MS/m) at room temperature. Renowned for its exceptional electrical conductivity, aluminum finds extensive application in diverse electrical uses such as power transmission lines, electrical conductors, and coils. This notable conductivity enables the smooth and efficient flow of electric current through aluminum coils, rendering them apt for dependable and efficient electricity conduction.

- Q: This question asks about the impact of aluminum coils on food quality, considering possible effects on taste, safety, and preservation.

- <p>Aluminum coils, when used in cooking or food packaging, can potentially affect the quality of food. If aluminum leaches into the food, it may alter the taste and could pose health risks due to aluminum's neurotoxic properties. However, modern food-grade aluminum coils are coated or anodized to prevent such leaching, ensuring food safety. They are also used in heat transfer for cooking, which can improve the efficiency and evenness of cooking, thus enhancing food quality. It's crucial to use high-quality, food-safe aluminum coils to avoid any negative impact on food quality and safety.</p>

Send your message to us

5083 Aluminum Coil for Sale - Pre-Painted Alu Foil in Different Colors

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords