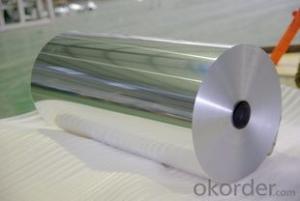

4x8 White Aluminum Sheets for Medicine Bottle Caps Colorful Aluminium Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Alloy: 8011

Temper: H14

Thickness: 0.17 to 0.21mm

Width: 30 to 800mm

Type: In coil

ID of the coil: 76mm, 152mm, etc.

Tensile strength: 125 to 155Mpa

Elongation: 2.0 to 3.0

Earring rate: < 2%

Coating type:

A. One side color coating and the other side transparent protective lacquer

B. Both sides transparent protective lacquer

Main applications: Aluminum closures, pharmaceutical vial seals, flip off / tear off vial seals

Packing: 80~100kgs per coil or as your requirement and use strong wooden box or pallet

Delivery Time: 25~35days after order and deposit

Payment: 30% T/T in advance, 70% balance payment against copy of B/L

Our Services

we have more than 15 year experience of coating

we gurantee quality and very good service!

the third company test shanghai ccic

we used chalco dc material only !

any more info, please contact me freely

- Q: What can I do to remove the paint from the painted aluminum sheet?

- The aluminum need scraping, the car is not easy to enamel paint.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more). Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.

- Q: What are the advantages of using aluminum sheet in construction?

- There are several advantages to using aluminum sheet in construction. Firstly, aluminum is lightweight, making it easier to handle and transport compared to other materials. Secondly, it is highly resistant to corrosion, which ensures durability and longevity of structures. Additionally, aluminum is a good conductor of heat and electricity, making it suitable for various applications such as electrical wiring. Lastly, aluminum is recyclable, making it an environmentally friendly choice for construction projects.

- Q: When Aluminium nitrate is heated , i got yellow amorphous solid which did not not melt on further heating. What compound is that?

- l would say you have mostly aluminum oxide as a product which probably contains some Nitrogen dioxide gas, a second product of the decomposition of aluminum nitrate. If I were you I would not heat nitrate salts as they can explode upon heating. they also need to be kept away from any kind of reducing agent such as powdered metals, or any fuels, reactions can be violent.

- Q: Can aluminum sheet be used for signage?

- Certainly! Aluminum sheet is a viable option for signage purposes. Its durability, versatility, and cost-effectiveness make it a popular choice among sign makers. Being a lightweight material, it is resistant to corrosion, making it suitable for both indoor and outdoor signage. With aluminum sheet, one can easily cut, shape, and form it into various sizes and designs, allowing for customizable signage options. Moreover, it is effortless to print or engrave upon, making it perfect for displaying text, graphics, and logos. Its sleek and professional appearance enhances its appeal for signage purposes. In conclusion, aluminum sheet is an excellent choice for signage due to its durability, versatility, and aesthetic qualities.

- Q: Does aluminum sheet require special handling during transportation?

- Yes, aluminum sheets typically require special handling during transportation. This is because aluminum is a lightweight yet fragile material that can easily dent, scratch, or bend. To prevent such damages, it is important to handle aluminum sheets with care, avoiding rough handling, excessive bending, or stacking heavy objects on top. Additionally, protective measures like using padding or wrapping the sheets in protective material can help ensure their safe transportation.

- Q: Are 101 aluminum sheets suitable for food packaging?

- Indeed, 101 aluminum sheets prove to be apt for food packaging purposes. The food packaging industry widely embraces aluminum owing to its remarkable attributes. Notably, it boasts a lightweight nature, durability, and resilience against corrosion, rendering it an ideal substance for maintaining the freshness and caliber of food products. Moreover, aluminum serves as a commendable shield against light, moisture, and oxygen, thereby prolonging the shelf life of packaged edibles. Thus, it is evident that opting for 101 aluminum sheets is a fitting decision for food packaging endeavors.

- Q: What is the corrosion resistance of 101 aluminum sheets in saltwater environments?

- The corrosion resistance of 101 aluminum sheets in saltwater environments is generally considered to be good. However, prolonged exposure to saltwater can still cause some level of corrosion over time.

- Q: Can aluminum sheets be polished?

- Yes, aluminum sheets can be polished. Aluminum is a relatively soft metal, which makes it easier to polish compared to harder metals like stainless steel. Polishing aluminum sheets involves using abrasive materials such as sandpaper or polishing compounds to remove any imperfections, scratches, or oxidation on the surface. The process typically involves several stages of polishing with different grits of sandpaper or polishing compounds, gradually achieving a smoother and more reflective surface. Polished aluminum sheets are commonly used in various applications, including automotive parts, architectural elements, and decorative items, as the polishing process enhances the metal's appearance and provides a lustrous and reflective finish.

- Q: What are the safety standards for aluminum sheets utilized in construction?

- <p>Yes, there are safety standards for aluminum sheets used in construction. These standards ensure the material's quality, strength, and suitability for various applications. They include specifications for thickness, alloy type, and surface treatment. International standards such as ASTM B209 (for aluminum sheet and plate) and EN 485 (for aluminum and aluminum alloy sheets) govern the production and use of aluminum sheets in construction. Compliance with these standards is crucial for safety, durability, and to meet regulatory requirements in different regions.</p>

- Q: How are the aluminum plates cut?

- A little thick with shears or plasma cutting machine, cutting machine words cut out if more smooth, no burr, but the pattern is simple, can be arbitrary cutting plasma cutting machine, but cutting burrs, rough.

Send your message to us

4x8 White Aluminum Sheets for Medicine Bottle Caps Colorful Aluminium Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords