Msc Aluminum Sheets - Aluminium Composite Panel for Insulation Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

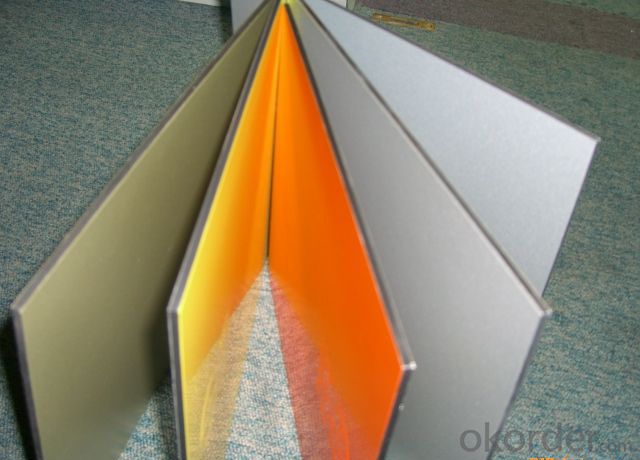

Structure of Aluminium Compoosite Pannel for Insulation Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Compoosite Pannel for Insulation Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Compoosite Pannel for Insulation Application:

Aluminium Compoosite Pannel for Insulation Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: An aluminum engine block has a volume of 4.77 and a mass of 12.88 .

- For the best answers, search on this site okorder (2.7 g / cm?) x (1 kg / 1000 g) x (100 cm / 1 m)? = 2700 kg / m?

- Q: I recently had a new bridge plate and knobs made from aluminum for my guitar. They are bare uncoated aluminum. How would I go about protecting the parts from oxidation and corrosion? I just worry about the bridge plate because of sweat from playing my guitar near the bridge. There are no local places to get the parts chromed or anodized unfortunately.

- in case you have coverage or can cope with to pay for to - flow see an Ear nostril Throat wellbeing care professional (additionally spoke of as otolaryngologist or ENT for short) it incredibly is the main secure and smartest element to do. maximum probable he will prescribe an ear flush for you that works o.k.. additionally, listening to in triplicate may well be a symptom of nerve inflammtion or different ailment which will properly be examined for quite truthfully by potential of a doctor. Odds are this is not something, yet extra effective risk-free than sorry.

- Q: Is it possible to incorporate windows made from recycled materials into a construction project?

- <p>Yes, you can use windows made from recycled materials in your project. There are eco-friendly windows available that are manufactured using recycled glass or other sustainable materials. These windows can offer similar performance to traditional ones while reducing the environmental impact of your construction. It's important to check the quality and certifications of the recycled windows to ensure they meet your project's requirements.</p>

- Q: I broke the swing-arm of a cut-off saw, need to know how to weld it back. I have a stick welder and can weld steel, but have never messed with cast aluminum.

- I also stick weld and have never done aluminum,but several years ago I bought aluminum welding rod from I think it was Northern Tool.It is a zinc based 1/8 bare rod you use with a propane torch.It worked for me and probably will for you.TIG would be overkill for that part.

- Q: Can the aluminum sheets be used for manufacturing musical instruments?

- Yes, aluminum sheets can be used for manufacturing musical instruments. Aluminum is a lightweight and versatile material that offers several advantages for instrument manufacturing. It is known for its excellent sound transmission properties, which makes it suitable for creating resonant and vibrant tones in musical instruments. Additionally, aluminum is highly durable and resistant to corrosion, ensuring that the instruments will withstand the test of time. Many percussion instruments, such as cymbals and bells, are commonly made from aluminum sheets due to their ability to produce clear and rich sounds. Moreover, aluminum can also be shaped and formed into various instrument components, making it a popular choice for constructing brass instruments like trumpets and trombones. Overall, aluminum sheets are a viable option for manufacturing musical instruments and have been successfully utilized in the industry.

- Q: What is the maximum sheet size available for aluminum sheets?

- The maximum sheet size available for aluminum sheets varies depending on the specific supplier and manufacturer. However, commonly available sheet sizes for aluminum range from 4 feet by 8 feet (1219mm x 2438mm) to 5 feet by 10 feet (1524mm x 3048mm).

- Q: This question asks for methods to prevent rusting on aluminum sheets while they are being stored or transported.

- <p>To prevent rusting on aluminum sheets during storage and transportation, follow these steps: Store the sheets in a dry, cool environment away from moisture and humidity. Use protective coverings such as plastic wraps or sheets to shield them from dust and water. Avoid stacking them directly on the ground; use pallets or racks to keep them elevated. Regularly inspect the sheets for any signs of moisture or damage. If possible, apply a protective coating or sealant specifically designed for aluminum to create a barrier against corrosion. Proper handling and packaging can also reduce the risk of scratches or dents that could lead to rust.</p>

- Q: I bought a house with aluminum wiring. Its about 1600 square feet. I have not had any problems with the electric but I read all these story's about how terrible aluminum wiring is.. is it worth the cost to replace? Most houses on my street have it also.. they have had no problems.. house was built in 79.How much would it cost to replace? would walls have to come down to do it?

- It has loosing joints problem between aluminum wire and copper screw joint. Some house caught fire happen on the wall outlet or power panel box. All the joints must use aluminum screw to join aluminum wire. Join copper with aluminum,the joint creates thermo-effect and heat builds up.

- Q: What are the common thicknesses of aluminum sheets used in construction?

- The common thicknesses of aluminum sheets used in construction vary depending on the specific application and requirements. However, some commonly used thicknesses include 0.032 inches (0.81mm), 0.040 inches (1.02mm), 0.050 inches (1.27mm), and 0.063 inches (1.60mm). These thicknesses are often used for architectural applications such as wall panels, roofing, and siding. Thicker aluminum sheets, such as 0.080 inches (2.03mm) and 0.125 inches (3.18mm), are also used in heavier construction applications such as structural components, support beams, and decking. It is important to note that these thicknesses are just examples and can vary depending on the specific project requirements and engineering specifications.

- Q: How does aluminum sheet perform in extreme temperatures?

- Aluminum sheet performs exceptionally well in extreme temperatures due to its unique properties. One of the key advantages of aluminum is its high thermal conductivity, which means it can rapidly transfer heat. This property allows aluminum sheet to quickly adjust to extreme temperatures, preventing warping or cracking that can occur with other materials. Additionally, aluminum has a high melting point of around 660 degrees Celsius, making it ideal for applications in high-temperature environments. It remains structurally stable and does not lose its strength or integrity when exposed to extreme heat. Moreover, aluminum has a low coefficient of thermal expansion, meaning it expands and contracts minimally with temperature changes. This characteristic enables aluminum sheet to maintain its shape and dimensions even when subjected to extreme temperature fluctuations. Furthermore, aluminum has excellent corrosion resistance, which is further enhanced by an oxide layer that forms naturally on its surface. This oxide layer protects the aluminum from chemical reactions and prevents it from deteriorating even in harsh environments or extreme temperatures. In summary, aluminum sheet performs exceptionally well in extreme temperatures due to its high thermal conductivity, high melting point, low coefficient of thermal expansion, and excellent corrosion resistance. These properties make it a reliable choice for various applications, including aerospace, automotive, and industrial sectors, where performance under extreme temperatures is crucial.

Send your message to us

Msc Aluminum Sheets - Aluminium Composite Panel for Insulation Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords