Polyester Coated Roof Aluminum Sheets - Decorative Wall Aluminium Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

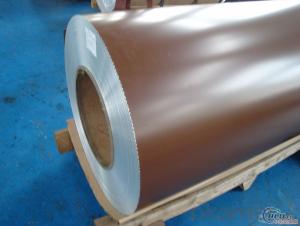

1.Structure of Aluminium Coils for Decoration Wall with Polyester Coating

Aluminium Coils for Decoration Wall with Polyester Coatingis one semi-finished aluminium material. The coils are widly used in the building,decoration and aluminium circle. The alloy AA5052 is the most common alloy in the aluminium industry. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils for Decoration Wall with Polyester Coating

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Aluminium Coils for Decoration Wall with Polyester Coating

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA1100 | HO | 0.2MM-3MM | 1000-1500MM | Max 3 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are the aluminum sheets suitable for manufacturing electronic enclosures?

- Yes, aluminum sheets are suitable for manufacturing electronic enclosures. Aluminum is a popular choice for electronic enclosures due to its excellent combination of strength, durability, and lightweight properties. It offers good electrical conductivity, making it suitable for dissipating heat generated by electronic components. Additionally, aluminum sheets can be easily shaped, formed, and machined to meet the specific requirements of electronic enclosures, allowing for customization and flexibility in design. Its corrosion resistance properties also make it suitable for protecting electronic devices from environmental factors. Overall, aluminum sheets provide an ideal material solution for manufacturing electronic enclosures.

- Q: Is it possible to utilize aluminum sheets for creating signs or banners?

- <p>Yes, you can use aluminum sheets to make signs or banners. Aluminum is a popular choice due to its durability, lightweight, and resistance to weather conditions. It can be easily cut, shaped, and printed on, making it ideal for outdoor signage. Additionally, aluminum sheets can be coated or laminated to enhance their visual appeal and protect against scratches and fading.</p>

- Q: What are the common sizes of aluminum sheet?

- The sizes of aluminum sheets commonly differ based on specific requirements and industry applications. However, the market offers some standard sizes that are readily available. These sizes typically vary in thickness from 0.025 inches to 0.125 inches and are offered in different widths and lengths. Among the common width options are 36 inches, 48 inches, and 60 inches, while the length can range from 96 inches to 144 inches. Furthermore, smaller sizes like 12 inches by 24 inches or 24 inches by 24 inches can also be found, which are frequently utilized for smaller projects or crafts. It should be noted that specialized aluminum sheet suppliers can provide custom sizes as well.

- Q: Can aluminum sheet be used for electrical connectors?

- Indeed, aluminum sheet can be utilized for electrical connectors. Aluminum, being an excellent conductor of electricity, finds widespread usage in diverse electrical applications, connectors included. Lightweight, cost-effective, and possessing commendable thermal and electrical conductivity characteristics, aluminum proves to be an advantageous choice. Nevertheless, it is important to acknowledge that aluminum exhibits lower electrical conductivity in comparison to copper, the predominant material employed for electrical connectors. Consequently, aluminum connectors may encounter greater resistance and lower capacity for carrying current when pitted against their copper counterparts. Nevertheless, through proficient design and engineering, these limitations can be overcome, rendering aluminum sheet a viable alternative for electrical connectors in specific scenarios.

- Q: Can the aluminum sheets be used for manufacturing chemical piping systems?

- Yes, aluminum sheets can be used for manufacturing chemical piping systems.

- Q: How does 1200X1200X15 6061 aluminum, CNC processing, the plane degree can reach the number of my clients to 0.2, but I used to use the MS 1000X1500X70 to the material processing, the flatness is only 1, please experienced friend to help, thank you

- The first rough machining, no precision position of the first place, finishing allowance for heat treatment of unilateral 0.15MM, and then remove the stress of 420 degrees Celsius for 4 hours, with the furnace cooling (very important), doing fine processing, can guarantee within 0.03

- Q: I have a problem when machining aluminium in my machine shop. There are times when the machines aluminium surface turns yellowish (somtimes brown). I do not know what is the main cause of the problem. Is it due to the coolant used?

- Aluminum oxides may appear in different colors depending on hydration states and other variables. Look in a CRC Handbook of Chemistry Physics if available for aluminum compounds and their colors. The colors that you see may also have as much to do with the surface finish as the color of the material on the surface. A microscopically rough surface will appear dark next to a polished surface due to light scattering. I will agree with Ling in principle, but not on details. EDS detection limits on homogeneous samples can be better than 0.1%, although not so good for elements at the light end of the detection range. Current detectors can detect chlorine (a common culprit for aluminum discoloration) at about 0.1%. Your problem with detection and one that Ling has addressed previously may be that a thin film of contamination would not be easily detected by EDS. As Ling suggests, SIMS is a good technique for detecting thin films and low concentrations. The problem with SIMS in this case may be that the detection limits are too good and the technique cannot be quantified. SIMS would detect 2 ppm of chloride and you couldn't tell for sure whether it was 2 ppm, which is probably not an issue here, or 2000 ppm, which would be significant. I would suggest x-ray photoelectron spectroscopy (ESCA or XPS) as an alternative for further study. The technique will analyze thin films (20 A) and detection limits are good enough (about 0.1%). In addition, XPS will give you information about the compounds present, e.g. whether the oxygen is aluminum oxide, aluminum hydroxide, etc. Good Luck.

- Q: What is the thickness range available for aluminum sheets?

- The thickness range available for aluminum sheets typically varies from 0.006 inches (0.15mm) to 0.25 inches (6.35mm), depending on the specific requirements and application.

- Q: What is the yield strength of aluminum sheets?

- The yield strength of aluminum sheets can vary depending on the specific grade and thickness of the sheet. However, on average, aluminum sheets have a yield strength ranging from 14,000 to 24,000 pounds per square inch (psi).

- Q: have been taking an over the counter Antacid consistently for the past 8 years as a daily source of extra calcium per the bottle. Now, I am getting many nerve problems, similar to Lou Gehrig's disease. I am a healthy 38 year old male who excersises, eats right and is generally health conscious. I am concerned that unknowingly I have toxified my body with the aluminum that apparently is in Antacid. I did not know this until now or of course I would not have gone any where near it.Can taking Antacid lead to nerve problems such as Lou Gehrig's disease?

- Aluminum okorder /

Send your message to us

Polyester Coated Roof Aluminum Sheets - Decorative Wall Aluminium Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords