Heavy Aluminum Baking Sheets - Aluminum Coils for Cold Rolling Without Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

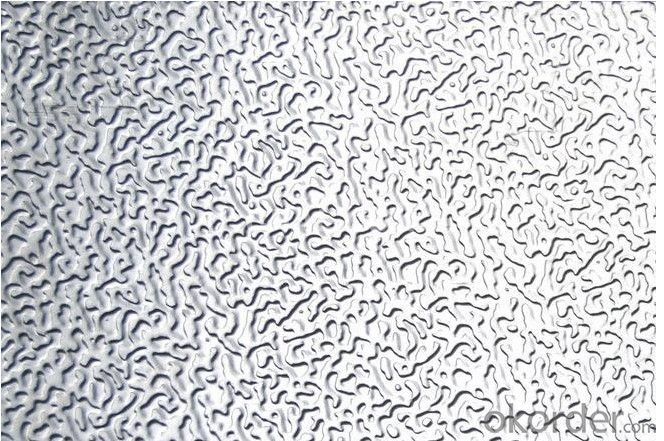

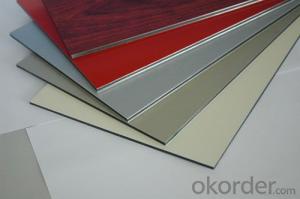

1.Structure of Aluminium Coils for Cold Rolling without Color

Aluminium Coils for Cold Rolling without Color are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils for Cold Rolling without Color

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Aluminium Coils for Cold Rolling without Color

4. Product Specification of Aluminium Coils for Cold Rolling without Color

| Alloy | Temper | Thickness | Width | Coating Thickness |

| AA1050 | H14 | 0.2-3MM | 1000-1800MM | 20-25 MICRONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: what are the differences between aluminium , iron , steel.... properties like strength , durability , corrosion resistance properties...finally which is cost efficient and best for all purpose..??

- steel okorder /

- Q: Are aluminum sheets suitable for outdoor uses like fences or signs?

- <p>Yes, aluminum sheets are commonly used for outdoor applications such as fences and signage. Aluminum is lightweight, durable, and resistant to corrosion, making it ideal for outdoor conditions. It can withstand various weather elements without rusting. Additionally, aluminum can be easily formed into different shapes and sizes, and it's available in a wide range of colors and finishes, which makes it versatile for both functional and aesthetic purposes in outdoor settings.</p>

- Q: How would you write the formula for aluminum sulfate and calcium chloride?

- AlSO4 CaCl

- Q: I got nauseous the other day and that day one thing I ate was hamburger baked for 1 hour on aluminum foil with tomatoes mixed in. Is it possible the upset stomach was caused by the tomatoes reacting with the foil?

- no that wouldn't make you sick. i line all my pans with foil before baking because it makes it much easier to clean the pans.

- Q: A dry aluminium foil paper can be bring out from oven with no burn on finger but if foil has some moisture it will result in burn why?

- It isn't the foil that is burning you--it's the water. Aluminum foil is a good heat conductor. This means that when you expose the foil to the air, it will cool off very rapidly (rapidly reaching room temperature). Water is NOT a good heat conductor, in fact, it likes to hold onto it's heat. So while the dry foil may come to room temperature (or just warm to the touch) in a few seconds, the water will stay hot for much longer (depending on how much water there is obviously). It's really the same as trying to grab a baked potato wrapped in foil off of the grill. If you grab the potato you will burn your hand (because the potato is holding A LOT of heat), but if you carefully peel away the foil, you can touch and take the foil off with your bare hand. I should say that the mass of the foil also plays a role here. The foil is not very massive and thus does not hold a lot of raw energy to begin with (also because it's a good heat conductor it dissipates quickly). Bu if you put an aluminum can (or a brick of aluminum) in the oven, I guarantee that it would stay hotter for much longer than just a piece of aluminum foil.

- Q: I was watching an old Star Trek movie. The last one with the full original cast; where they bring two whales into the future. There is a scene in which Scotty and Bones are trying to get material to build a giant tank to hold the whales inside the Klingon space ship. They go to a manufacturer and offer him the formula for Clear Aluminum in exchange for the materials. Scotty and Bones don't know who invented Clear Aluminum and the manufacturer who will eventually place the patent in the 20th century didn't really invent it, so who did? If you think of this as a thought experiment would this prove that other universes exist? Did Scotty and Bones create a new universe?

- In the novel, developed from the original screenplay (which featured information that did not end up being mentioned in the film), Scotty was already aware that the chap he gave the transaprent aluminium formula to was recorded as its inventor. Therefore, the plot as intended suggested looped or self-generating causality. This is the outcome referred to in other predestination paradoxes, like the one about going back in time 100 years and becoming your own great-grandfather. The character in the film who Scotty gives the formula to is called Marcus Nichols. he was played by an American actor called Alex Henteloff. For reasons of brevity or simplicity of plot, the film leaves the viewer thinking that Scotty et al didn't know who the inventor was, but Scotty does have the line How d'you know he wasn't the man who invented it?, delivered to Dr McCoy, which could be taken as an indication that Scotty DID know and was just being a smart-**** to McCoy. As a thought experiment, this wouldn't prove the existence of multiple universes, just that the outcome was possible without changing their own future. Proof would require more information that is also missing from the screenplay and film. In reality, there is no such thing as transparent aluminium, but there are aluminium-based ceramics which are transparent.

- Q: How do aluminum sheets perform in terms of electrical conductivity?

- Aluminum sheets are known for their excellent electrical conductivity. They are highly conductive, ranking second only to copper in terms of electrical conductivity among common metals. This high conductivity makes aluminum sheets an ideal choice for various electrical applications, including wiring, power transmission, and electrical components. The low resistivity of aluminum allows for efficient transfer of electricity, ensuring minimal energy loss during transmission. Additionally, aluminum sheets are lightweight, making them a preferred material for electrical systems where weight reduction is desired. Overall, aluminum sheets offer exceptional electrical conductivity, making them a reliable and efficient choice for electrical applications.

- Q: Can 101 aluminum sheets be customized in terms of size and thickness?

- Yes, 101 aluminum sheets can be customized in terms of size and thickness. Aluminum sheets can be cut to the desired size and thickness using various cutting techniques such as shearing, sawing, or laser cutting. Additionally, aluminum sheets can also be rolled or stretched to achieve the desired thickness. Customizing the size and thickness of aluminum sheets allows them to be tailored to specific applications or requirements.

- Q: i want to build a smelter to recycle aluminum auto parts

- Aluminium is usually recycled in the following basic way[2]: In the case of products like aluminium drink cans, the cans are shredded and ground into small pieces. The small pieces are then melted in a furnace to produce molten aluminium (by the end of this stage the recycled aluminium is indistinguishable from virgin aluminium and so further processing is identical for both). Some minor adjustments to the actual composition of the final product is required to eliminate impurities and to conform the recycled aluminium to the proper amalgam from which different materials are manufactured, including slightly different compositions for can bodies and lids. The molten aluminium is then poured in to moulds to create large ingots. The ingots are then forced through rollers to create sheets of aluminium of whatever thickness is required for the product the metal will be used in. The scrap aluminium is separated into a range of categories i.e. irony aluminium (engine blocks etc), alloy wheels, clean aluminium Depending on the specification of the required ingot casting will depend on the type of scrap used in the start melt. Generally the scrap is charged to a reverbatory furnace (other methods appear to be either less economical and/ or dangerous)and melted down to form a bath. the molten metal is tested using spectroscopy on a sample taken from the melt to determine what refinements are needed to produce the final casts. After the refinements have been added the melt may be tested several times to be able to fine tune the batch to the specific standard Once the correct recipe of metal is available the furnace is tapped and poured into ingot moulds, usually via a casting machine. The melt is then left to cool, stacked and sold on as cast silicon aluminium ingot to various industries for re-use.

- Q: Is aluminum sheet magnetic?

- No, aluminum sheet is not magnetic.

Send your message to us

Heavy Aluminum Baking Sheets - Aluminum Coils for Cold Rolling Without Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords