Aluminium Checker Plate for Boat Deck Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium Checker Plate for Boat Deck Use

l Product Information

1. Alloy number: 1100, 3003,1050,1060, 5052.

2. Temper: H14, H18, H12, H16, H22, H26, H24.

3. Thickness: 0.8-10.0mm. width: 20-1600mm.

4. Tolerance: thick+/-0.02mm, width +/-0.5mm.

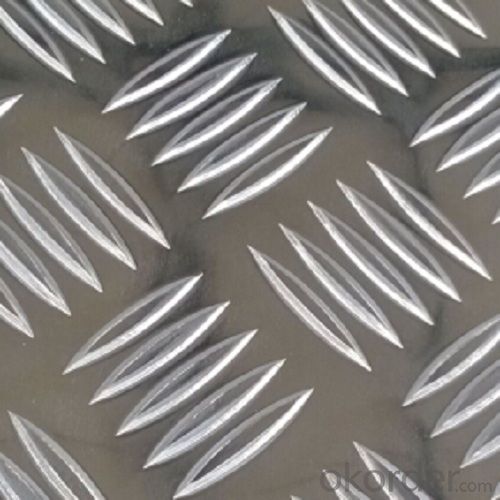

5. Pattern: Two bars, Three bars, Five bars and Diamond.

6. Surface brightness: bright surface or normall surface.

7. Application: trailer, truck, decking, flooring, stairs, steps, building industry.

8. Loading port: Shanghai or main port.

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received original L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: We want to buy an AirBake insulated aluminum pizza pan. What is insulated aluminum? We want to make sure that it is not something toxic like the non-stick material on pans.

- AirBake is available either natural (just plain aluminum) or nonstick, which is coated with a similar material to other nonstick cookware. What's insulated about it is this: The pan is actually two layers separated by an air pocket. If you put it directly over a heating element, the lower layer heats the air inside, which heats the upper layer. A single-ply aluminum sheet will get very hot and tend to burn the pizza, because it absorbs radiant energy from the element more quickly than the pizza can conduct it away. The insulating air layer slows down the heat transfer and helps to keep your pizza from burning. So if you prefer non-non-stick cookware, get the AirBake Natural line.

- Q: I know aluminum has 3 valence electrons and oxygen has 7, but if anyone could explain the chemical formula to me it would be great.

- The chemical formula of aluminium oxide is Al2O3 An aluminium ion has a 3+ charge, because it loses 3 electrons when it reacts. An oxygen ion has a 2- charge, because it gains 2 electrons when it reacts. In aluminium oxide, the charges of the ions need to cancel out. So... 2 aluminium ions -- 6+ total charge , 3 oxygen ions -- 6- total charge The charges cancel out.

- Q: Are there any limitations on the bending or shaping of aluminum coils?

- Aluminum coils do have limitations when it comes to bending or shaping. Despite being a soft and malleable metal, there are factors that can affect its bendability. The thickness of the aluminum coil plays a role in its bendability. Thicker coils are generally more difficult to bend compared to thinner ones because they have increased resistance to deformation. The temper or hardness of the aluminum coil also affects its bendability. Different tempers, such as soft, half-hard, or hard, have varying degrees of malleability. Soft tempers are easier to bend, while harder ones require more force and may be prone to cracking or breaking during bending. The desired bend or shape's design and complexity can impose limitations as well. Sharp bends or intricate shapes may cause the aluminum coil to crack or deform, especially if it lacks proper support or if the bending radius is too small. Impurities, defects, or alloying elements present in the aluminum coil can also impact its bendability. These factors can lead to inconsistencies in the material's mechanical properties, making it more susceptible to cracking or breaking during bending or shaping. Therefore, it is crucial to consider the thickness, temper, design, and quality of the aluminum coil to ensure successful and safe bending and shaping.

- Q: How do aluminum coils contribute to energy efficiency?

- There are several ways in which aluminum coils contribute to energy efficiency. To begin with, aluminum is a highly conductive metal, enabling it to transfer heat efficiently. When utilized in HVAC systems, aluminum coils aid in the efficient transfer of heat between the air and the refrigerant, resulting in faster cooling or heating of the space. Secondly, aluminum coils possess a lightweight nature and boast a high strength-to-weight ratio. This particular characteristic makes them easier to handle and install, ultimately reducing the overall weight of the HVAC system. The reduced weight not only enhances transportation and installation efficiency but also lessens the burden on the building structure. Moreover, aluminum coils exhibit durability and resistance to corrosion. This longevity ensures the smooth operation of the HVAC system for an extended period, thereby minimizing the need for frequent repairs or replacements. Consequently, less energy is wasted on maintenance or component replacements, resulting in improved energy efficiency. Additionally, aluminum is a recyclable material, and the utilization of aluminum coils in HVAC systems promotes sustainability. The recycling process for aluminum requires significantly less energy compared to the production of new aluminum, thereby reducing the overall carbon footprint and energy consumption. Lastly, aluminum coils are frequently manufactured with enhanced fin designs and advanced technology, such as microchannel coils. These advancements increase the surface area of the coil, thereby enhancing heat transfer efficiency and reducing the energy required for cooling or heating. In conclusion, aluminum coils contribute to energy efficiency by facilitating efficient heat transfer, reducing system weight, promoting durability, supporting sustainability through recycling, and incorporating advanced technology to enhance heat exchange.

- Q: Explain how aluminum coils are connected to electronics.

- <p>Aluminum coils play a significant role in the electronics industry due to their high electrical conductivity and low density. They are used in various components such as transformers, inductors, and chokes, where they help in the conversion and regulation of electrical energy. Aluminum's non-magnetic properties make it ideal for parts that need to be shielded from magnetic fields. Additionally, aluminum coils are used in heat sinks to dissipate heat generated by electronic devices, ensuring their efficient operation and longevity.</p>

- Q: Why do the layers loose when taking out coil after roll of aluminum 0.14?

- After rolling, the most possible reason may be poor deoiling effect. I think, for 0.14mm aluminum coil, the lining sleeve will not be forgotten. After rolling , oil ooze from aluminum layers, and the support of aluminum coil is not enough, leading to coil collapsing. The specific manifestations are that the edges of even round aluminum layers become like water ripple, and that the aluminum coils suddenly become uneven when taking out coil.

- Q: Is it safe to use steel wires for making jewelry or decorative items, and are there any potential health hazards associated with it?

- <p>Using steel wires for jewelry or decorations generally poses minimal health risks when used properly. However, there are a few considerations: allergic reactions can occur in individuals sensitive to nickel, which is often found in stainless steel. Additionally, improper use or sharp edges can lead to cuts or injuries. It's important to ensure that the steel is of high quality and that any jewelry made is smooth and free of sharp points to minimize the risk of injury. Regular cleaning and maintenance are also recommended to prevent any potential health risks associated with bacteria buildup or skin irritation.</p>

- Q: How are aluminum coils used in signage and advertising?

- Aluminum coils are commonly used in signage and advertising as a durable and lightweight material for creating various types of signs. These coils can be easily shaped, cut, and bent to form letters, logos, and other designs. Their corrosion-resistant properties make them suitable for outdoor use, ensuring longevity and durability. Additionally, aluminum coils are often coated or painted to enhance their aesthetic appeal and provide a smooth and polished finish. This versatility and flexibility make aluminum coils a popular choice for creating eye-catching and long-lasting signs and advertisements.

- Q: A bit of a question for the 1911 experts roaming around here. Per-say someone, who knew their way around a 1911 built one on an aluminum frame. To top it all off, if the finished gun were to be chambered in .38 super... how long would this combination last? I've heard horror stories about aluminum frames, and then I've heard some wonderful things... this question was to see if anyone had ever thought about/done this sort of thing before. Something tells me that Aluminum + .38 super wouldn't last too long... Most informative answer gets the ten point prize as usual.

- Aluminum might be corrosive resistant but it is softer than a stainless steel frame. It might be possible to shoot .38 super regular loads through it but any .38 super + P might cause a catastrophic failure of the weapon. Just my opinion.

- Q: What is the role of aluminum coils in the construction of railways?

- The construction of railways heavily relies on aluminum coils, which possess unique properties and advantages. These coils are widely utilized in the manufacturing of railway tracks and train cars. One of the primary functions of aluminum coils in railway construction is their contribution to lightweighting. Aluminum, being a lightweight material, is ideal for reducing the overall weight of railway components. This is significant because lighter trains and tracks require less energy for operation, leading to improved fuel efficiency and reduced operating costs. Additionally, the decreased weight of aluminum components allows for increased payload capacity, enabling trains to carry more passengers or freight. Another crucial role of aluminum coils lies in their corrosion resistance. Railways are exposed to various environmental conditions, such as moisture, salt, and extreme temperatures. Aluminum possesses excellent corrosion resistance properties, making it highly durable and long-lasting even in harsh environments. This diminishes maintenance and replacement costs associated with rust and corrosion, ensuring the longevity and reliability of the railway infrastructure. Furthermore, aluminum coils offer excellent conductivity, which is essential for electrical and signaling systems in railways. Aluminum's high electrical conductivity facilitates efficient power transmission and distribution, enabling seamless communication between trains, signaling devices, and control systems. This contributes to the safety and efficiency of railway operations. Moreover, aluminum coils can be easily formed and fabricated into various shapes, providing flexibility in railway design and construction. This versatility allows for the production of customized railway components, such as curved tracks or aerodynamic train carriages, to meet specific project requirements. In conclusion, the indispensable role of aluminum coils in railway construction is attributed to their lightweight, corrosion-resistant, conductive, and versatile nature. Their incorporation into railway infrastructure results in various benefits, including enhanced fuel efficiency, reduced maintenance costs, improved safety, and the ability to design and construct innovative railway systems.

Send your message to us

Aluminium Checker Plate for Boat Deck Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords