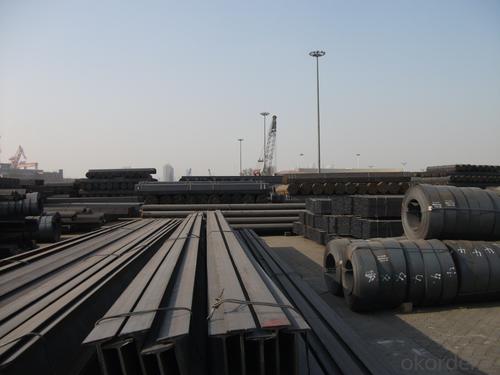

Alloyed Hot rolled I beams/Ibeams GB standard/JIS standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail:packed in bundle, suitable for sea transport (by container) or According to the clients`requirements

Delivery Detail:According to the actual weight

Specifications

joist steel

high quality and factory price

large inventories

short delievery time

good after-sales service

Country of Origin: China

Mill name: Ningbo Preah Vihear Steel Industry Co., Ltd.

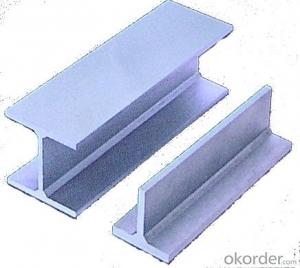

Commodity: H beam

Tolerance: Strictly according to the G/B and JIS standard

Delivery time: within 30days

Price term: CIF/ CFR according to clients requirements

Payment terms: 100%Irrevercable L/C At Sight or TT

Product Description

ACCORDING TO STANDARD: JIS G3192 OR GB/T11263-2005

H beam Section sizenma(mm)Weight (kg/m)

Height×BreadthWeb thichnessFlange thichness

100×1006816.9

125×1256.5923.6

150×15071031.1

175×1757.51140.4

200×20081249.9

250×25091471.8

300×300101593.0

300×3001515105.0

350×3501219134.9

400×4001321171.7

148×1006920.7

194×1506929.9

244×17571143.6

294×20081255.8

340×25091478.1

390×3001016104.6

440×3001118120.8

482×3001115110.8

488×3001118124.9

582×3001217132.8

588×3001220147.0

100×50579.3

125×606813.1

150×755714.0

175×905818.0

198×994.5717.8

200×1005.5820.9

248×1245825.1

250×1256929.0

298×1495.5832.0

300×1506.5936.7

346×1746941.2

350×17571149.4

396×19971156.1

400×20081365.4

446×19981265.1

450×20091474.9

496×19991477.9

500×200101688.1

596×199101592.4

600×2001117103.4

700×3001324181.8

800×3001426206.8

900×3001628240.1

- Q: Can steel H-beams be used for schools or educational buildings?

- Yes, steel H-beams can be used for schools or educational buildings. Steel H-beams provide excellent structural support and are commonly used in construction projects due to their strength, durability, and ability to withstand heavy loads. They can be used to create large open spaces and can easily accommodate different architectural designs. Additionally, steel is a sustainable and environmentally friendly material choice for educational buildings.

- Q: How do steel H-beams perform in terms of durability?

- Steel H-beams are renowned for their exceptional durability. Their composition and design grant them high resistance to bending, warping, and twisting, thus rendering them highly durable even in the most challenging scenarios. Steel H-beams are manufactured using robust and sturdy materials, like carbon steel or alloy steel, renowned for their exceptional strength and longevity. Furthermore, they are commonly hot-dip galvanized or coated with protective finishes, further augmenting their durability by preventing corrosion and rust formation. These characteristics endow steel H-beams with the ability to withstand heavy loads, extreme weather conditions, and other environmental factors, ensuring their long-lasting durability. All in all, steel H-beams are an optimal choice for structural applications that prioritize durability.

- Q: Can Steel H-Beams be recycled or reused?

- Yes, Steel H-Beams can be recycled and reused. Steel is one of the most recycled materials in the world, and H-Beams are no exception. When H-Beams are no longer needed, they can be collected and taken to recycling centers or scrap yards. The beams are then melted down and transformed into new steel products. Recycling H-Beams reduces the demand for raw materials and helps to conserve energy and resources. Additionally, if the H-Beams are still in good condition, they can be reused in construction projects, providing cost-effective and sustainable solutions. Overall, the ability to recycle and reuse Steel H-Beams contributes to a more environmentally friendly and sustainable construction industry.

- Q: Can steel H-beams be used in the construction of schools or educational buildings?

- Certainly, schools or educational buildings can indeed make use of steel H-beams in their construction. The utilization of steel H-beams in construction is quite prevalent due to their commendable attributes of strength, durability, and versatility. These beams offer substantial structural support and possess the ability to withstand heavy loads, rendering them suitable for large-scale establishments like schools. Furthermore, the fabrication and installation of steel H-beams are relatively simple, thereby reducing both construction time and expenses. Furthermore, steel qualifies as a sustainable material since it is recyclable, thus making it an environmentally conscious choice for educational structures. In summary, incorporating steel H-beams into the construction of schools and educational buildings guarantees the creation of a secure and long-lasting edifice that complies with all necessary standards and requirements for such establishments.

- Q: How do steel H-beams contribute to architectural design?

- Steel H-beams contribute to architectural design by providing structural support and stability to buildings. These beams are known for their high strength and durability, allowing architects to design structures with larger open spaces and flexible layouts. The use of H-beams also enables the creation of tall and slender structures, as they can bear heavy loads and resist bending or buckling. Additionally, their uniform shape and clean lines offer a sleek and modern aesthetic, enhancing the overall architectural appeal.

- Q: Can steel H-beams be used for theater or stage construction?

- Yes, steel H-beams can be used for theater or stage construction. Steel H-beams are commonly used in construction due to their high strength and load-bearing capacity. They provide structural support and stability, making them suitable for building stages and theater structures that require a strong foundation. Additionally, steel H-beams can be easily customized and fabricated to meet specific design requirements, making them versatile for various theater and stage configurations. They can be used for constructing stage platforms, trusses, rigging systems, and other structural components necessary for theater productions. The use of steel H-beams in theater and stage construction ensures a durable and safe environment for performances and allows for the implementation of complex stage designs.

- Q: Are steel H-beams resistant to pests and termites?

- Indeed, steel H-beams possess remarkable resistance against pests and termites. Unlike wood, which is vulnerable to termite infestation and harm, steel beams present a robust and enduring substitute. Termites are incapable of consuming or impairing steel, rendering it an optimal preference for construction endeavors in regions prone to termite infestation. Moreover, steel fails to provide a suitable habitat for other pests, including rodents, to inhabit or inflict harm. Consequently, steel H-beams furnish prolonged safeguarding against pest infestation, thereby establishing them as a dependable selection for structural support in buildings and various construction applications.

- Q: What are the different types of steel H-beam connections used in industrial buildings?

- There are several different types of steel H-beam connections commonly used in industrial buildings. These connections are designed to provide stability and support to the overall structure. Here are some of the most commonly used types: 1. Welded connection: This is the most common type of connection used in industrial buildings. It involves welding the H-beam to other structural members or plates. Welded connections provide excellent strength and rigidity, making them suitable for heavy-duty applications. 2. Bolted connection: In bolted connections, the H-beam is fastened to other structural members using bolts and nuts. This type of connection allows for easier disassembly and reassembly, making it convenient for buildings that may need to be modified or relocated in the future. 3. Pinned connection: Pinned connections allow for rotation at the joint, providing flexibility to the structure. This type of connection is commonly used in situations where movement or vibration needs to be accommodated, such as bridges or buildings located in earthquake-prone areas. 4. Moment connection: Moment connections are designed to transfer both vertical and horizontal forces between the H-beams and other structural members. These connections provide enhanced stability and resistance against bending moments, making them suitable for structures with high loads or complex geometries. 5. Shear connection: Shear connections are used to transfer shear forces between the H-beams and other structural members. These connections are typically designed to resist lateral loads and provide stability to the structure. The choice of H-beam connection type depends on various factors, including the load requirements, structural design, and construction method. Engineers and designers evaluate these factors to determine the most appropriate connection type for each specific application.

- Q: Can steel H-beams be used in residential balcony or terrace structures?

- Yes, steel H-beams can be used in residential balcony or terrace structures. Steel H-beams are often used in construction projects due to their strength and durability. They provide excellent structural support and can withstand heavy loads, making them suitable for supporting balconies and terraces. Additionally, steel H-beams can be customized and designed to meet specific architectural and engineering requirements, ensuring a safe and secure structure. However, it is crucial to consult with a qualified structural engineer or architect to determine the appropriate size and design of the steel H-beams for the specific residential balcony or terrace structure, taking into consideration factors such as the load-bearing capacity, local building codes, and environmental conditions.

- Q: How are steel H-beams connected to other structural elements?

- Steel H-beams, also known as I-beams, are commonly used in construction to provide structural support for various applications. These beams are connected to other structural elements in different ways depending on the specific design and requirements of the project. One common method of connecting steel H-beams to other structural elements is through welding. Welding is a process that involves melting the edges of the beams and fusing them together using a high-intensity heat source. This creates a strong and durable connection between the H-beam and the other elements. Welding is particularly useful when the connection needs to withstand high loads or forces. Another method of connecting steel H-beams is through bolting. Bolts are inserted through pre-drilled holes in the flanges or webs of the beam, and nuts are tightened to secure the connection. This method allows for easy disassembly and reassembly if required. Bolting is commonly used when the connection needs to be adjustable or when welding is not feasible due to specific project constraints. In addition to welding and bolting, steel H-beams can also be connected to other structural elements using various mechanical connectors. These connectors, such as brackets, plates, or cleats, are designed to provide a secure and rigid connection between the beam and the other elements. Mechanical connectors are often used in combination with welding or bolting to enhance the overall strength and stability of the connection. It is important to note that the specific method of connecting H-beams to other structural elements may vary depending on factors such as the load requirements, design considerations, and building codes. Professional engineers and construction experts carefully evaluate these factors to determine the most appropriate and efficient method of connection for each specific project.

Send your message to us

Alloyed Hot rolled I beams/Ibeams GB standard/JIS standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords