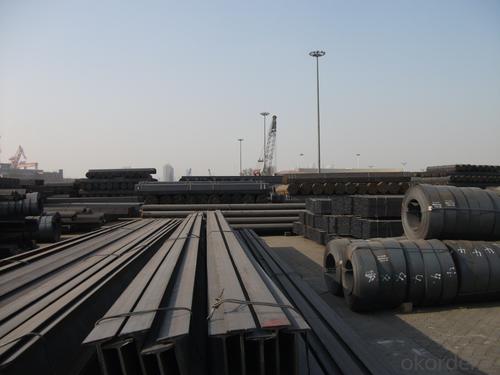

Hot rolled I beams/Ibeams GB standard/JIS standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail:packed in bundle, suitable for sea transport (by container) or According to the clients`requirements

Delivery Detail:According to the actual weight

Specifications

joist steel

high quality and factory price

large inventories

short delievery time

good after-sales service

Country of Origin: China

Mill name: Ningbo Preah Vihear Steel Industry Co., Ltd.

Commodity: H beam

Tolerance: Strictly according to the G/B and JIS standard

Delivery time: within 30days

Price term: CIF/ CFR according to clients requirements

Payment terms: 100%Irrevercable L/C At Sight or TT

Product Description

ACCORDING TO STANDARD: JIS G3192 OR GB/T11263-2005

H beam Section sizenma(mm)Weight (kg/m)

Height×BreadthWeb thichnessFlange thichness

100×1006816.9

125×1256.5923.6

150×15071031.1

175×1757.51140.4

200×20081249.9

250×25091471.8

300×300101593.0

300×3001515105.0

350×3501219134.9

400×4001321171.7

148×1006920.7

194×1506929.9

244×17571143.6

294×20081255.8

340×25091478.1

390×3001016104.6

440×3001118120.8

482×3001115110.8

488×3001118124.9

582×3001217132.8

588×3001220147.0

100×50579.3

125×606813.1

150×755714.0

175×905818.0

198×994.5717.8

200×1005.5820.9

248×1245825.1

250×1256929.0

298×1495.5832.0

300×1506.5936.7

346×1746941.2

350×17571149.4

396×19971156.1

400×20081365.4

446×19981265.1

450×20091474.9

496×19991477.9

500×200101688.1

596×199101592.4

600×2001117103.4

700×3001324181.8

800×3001426206.8

900×3001628240.1

- Q: How do you calculate the load-bearing capacity of steel H-beams?

- To calculate the load-bearing capacity of steel H-beams, several factors need to be considered. Firstly, you need to determine the cross-sectional area of the H-beam, which can be done by measuring the dimensions of the flanges and web. The flanges are the horizontal parts of the H-beam, while the web is the vertical part that connects the flanges. Next, you should identify the material properties of the steel being used, such as the yield strength and the modulus of elasticity. The yield strength is the maximum stress that the steel can withstand without permanent deformation, while the modulus of elasticity measures the stiffness of the material. Once these parameters are known, you can calculate the moment of inertia of the H-beam. The moment of inertia is a measure of how resistant the beam is to bending. It depends on the dimensions and shape of the cross-section of the beam. With the moment of inertia, you can then calculate the section modulus, which is the ratio of the moment of inertia to the distance from the neutral axis of the beam to the extreme fiber. The section modulus indicates the resistance of the beam to bending and is used to determine its load-bearing capacity. Finally, the load-bearing capacity of the steel H-beam can be calculated by dividing the section modulus by a safety factor. The safety factor accounts for uncertainties in the design and manufacturing processes and ensures that the beam can handle loads without excessive deflection or failure. The specific safety factor to be used depends on the intended application and the level of risk involved.

- Q: Can steel H-beams be used in theater stage construction?

- Certainly! Steel H-beams are indeed suitable for theater stage construction. Their strength, durability, and load-bearing capabilities make them a popular choice in the construction industry. They are widely used for constructing buildings, bridges, and various structures due to their ability to provide excellent support for heavy loads. When it comes to theater stage construction, steel H-beams can serve as essential structural elements. They play a crucial role in supporting the stage platform, lighting rigs, and other equipment. By offering stability and withstanding the weight of different stage elements, they ensure the safety of performers and crew members. Moreover, steel H-beams are highly versatile and can be easily customized and adjusted to meet the specific requirements of any theater stage design.

- Q: What are the different factors that affect the cost of steel H-beams?

- There are several factors that can affect the cost of steel H-beams. 1. Raw material costs: The price of steel is influenced by various factors such as supply and demand, global economic conditions, and the cost of raw materials. Fluctuations in these factors can impact the overall cost of steel H-beams. 2. Manufacturing process: The production process for steel H-beams involves various steps such as melting, casting, rolling, and finishing. The complexity and efficiency of these processes can affect the cost of production, which in turn affects the final price of H-beams. 3. Size and weight: The dimensions and weight of steel H-beams play a significant role in determining their cost. Larger and heavier H-beams require more raw materials and additional manufacturing processes, resulting in higher costs. 4. Quality and grade: The quality and grade of steel used in H-beams can also influence their cost. Higher-grade steels with superior strength and durability tend to be more expensive compared to lower-grade options. 5. Market demand: The demand for steel H-beams can also impact their cost. When demand is high and supply is limited, prices tend to rise. Conversely, when demand is low and supply exceeds it, prices may decrease. 6. Transportation and logistics: The cost of transporting steel H-beams from the manufacturing site to the buyer's location can add to the overall cost. Factors such as distance, mode of transportation, and fuel prices can affect transportation costs. 7. Market competition: The level of competition among steel manufacturers and suppliers can influence the pricing of H-beams. In a highly competitive market, companies may offer competitive pricing to attract customers, while in less competitive markets, prices may be higher. 8. Currency exchange rates: Steel is a globally traded commodity, and fluctuations in currency exchange rates can impact the cost of imported steel H-beams. Changes in exchange rates between the country of origin and the destination country can affect the final price. It is important to consider these factors when estimating the cost of steel H-beams, as they can vary over time and have a significant impact on the overall budget for construction or manufacturing projects.

- Q: What are the environmental impacts of using steel H-beams?

- The use of steel H-beams in construction and infrastructure projects has both positive and negative environmental impacts. On the positive side, steel H-beams are highly durable and have a long lifespan, which means they can be reused or recycled when no longer needed. This reduces the demand for new steel production and minimizes the extraction of raw materials, saving energy and reducing greenhouse gas emissions associated with steel manufacturing. However, the production of steel H-beams does have some negative environmental impacts. The manufacturing process involves the extraction of iron ore, which requires significant energy inputs and contributes to air and water pollution. Additionally, the production of steel from iron ore releases large amounts of carbon dioxide, a major greenhouse gas that contributes to climate change. The transportation of steel H-beams from the manufacturing facilities to construction sites also has environmental implications. Shipping and trucking of these heavy materials consume energy and contribute to air pollution, especially if long distances are involved. Furthermore, the construction process itself can have localized environmental impacts. Excavation and site preparation for installing steel H-beams can disrupt natural habitats, leading to habitat loss and fragmentation. Construction activities may also generate noise, dust, and other pollutants that can impact air and water quality and affect nearby ecosystems and communities. Overall, while the use of steel H-beams offers various benefits in terms of durability and recyclability, it is important to consider the environmental impacts associated with their production, transportation, and construction. To mitigate these impacts, sustainable practices such as using recycled steel, optimizing transportation routes, and implementing proper construction site management should be adopted.

- Q: Do steel H-beams require special maintenance?

- Special maintenance is not usually necessary for steel H-beams. Nevertheless, it is recommended to conduct regular inspections and maintenance to guarantee their structural soundness and long lifespan. This entails promptly addressing any signs of corrosion or damage, such as cracks or bends. Furthermore, it is important to keep the H-beams clean and clear of debris or excessive moisture in order to prevent corrosion and maintain their overall state. Ultimately, despite the renowned durability and strength of steel H-beams, regular maintenance is crucial to ensure their ongoing performance and safety.

- Q: How do steel H-beams perform in terms of torsion resistance?

- Steel H-beams possess excellent properties for resisting torsion. These beams have an H-shape design which aids in distributing the load evenly, resulting in a high level of resistance against torsion forces. The combination of horizontal flanges and vertical web in the beam effectively counteracts twisting and bending moments, ensuring structural stability and preventing deformation. Furthermore, the utilization of high-quality steel in H-beams further enhances their ability to withstand torsion, as steel is a robust and enduring material capable of enduring substantial forces without yielding or breaking. In general, steel H-beams are widely regarded as one of the top choices for applications that necessitate exceptional torsion resistance, such as constructing frames, bridges, and industrial structures.

- Q: Can steel H-beams be fire-resistant?

- Yes, steel H-beams can be made fire-resistant through various methods such as applying fire-resistant coatings, enclosing them in fire-rated materials, or using fire-resistant construction techniques. These measures help to prevent or slow down the spread of fire and maintain the structural integrity of the H-beams during a fire event.

- Q: How are steel H-beams used in the construction of sports stadiums?

- Steel H-beams are a critical component in the construction of sports stadiums due to their strength and versatility. These beams, shaped like the letter "H," are designed to support heavy loads and provide structural stability. In sports stadium construction, H-beams are primarily used to form the skeleton framework of the building. They are typically used to create the structural supports for the roof, seating areas, and other critical areas of the stadium. One of the main advantages of H-beams is their ability to span long distances while carrying heavy loads. This makes them the ideal choice for creating large, open spaces within the stadium, such as the playing field, concourses, and seating areas. Additionally, H-beams are often used in conjunction with other steel components, such as columns and trusses, to create a robust and durable structure. This combination allows for efficient load distribution and ensures the stadium can withstand the forces it may experience, including wind, seismic activity, and the weight of the spectators. Another benefit of using steel H-beams in sports stadium construction is their adaptability. These beams can be easily fabricated to specific lengths and sizes, allowing for customized designs and efficient construction processes. They can also be easily joined together using welding or bolting techniques, enabling rapid assembly on-site. Furthermore, steel H-beams are highly resistant to corrosion, which is essential in sporting stadium environments where moisture and harsh weather conditions can be present. This resistance helps to ensure the longevity and safety of the structure over time. Overall, steel H-beams play a crucial role in the construction of sports stadiums by providing the necessary strength, stability, and versatility required for these large-scale structures. Their ability to support heavy loads, span long distances, and withstand various forces makes them an ideal choice for creating safe, functional, and visually stunning sporting venues.

- Q: How do steel H-beams perform in extreme temperatures?

- Steel H-beams perform well in extreme temperatures due to their high thermal conductivity and low thermal expansion coefficient. This means that they can effectively dissipate heat and resist deformation caused by thermal expansion and contraction. Additionally, steel has a high melting point, making it suitable for use in extreme temperature conditions. However, it is important to note that prolonged exposure to extremely high temperatures can eventually weaken the steel, causing it to lose some of its structural integrity. Therefore, it is crucial to consider the specific temperature range and duration when evaluating the performance of steel H-beams in extreme temperatures.

- Q: How do steel H-beams perform in terms of vibration resistance?

- Steel H-beams are known for their excellent vibration resistance properties. The structural design, with a wide flange and a deep section, allows for increased stiffness and strength, resulting in minimal deflection and vibration under dynamic loads. This makes steel H-beams highly effective in withstanding vibrations caused by external forces, ensuring structural stability and minimizing potential damage or fatigue.

Send your message to us

Hot rolled I beams/Ibeams GB standard/JIS standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords