Al-Zinc Coated Steel Coil for construction roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

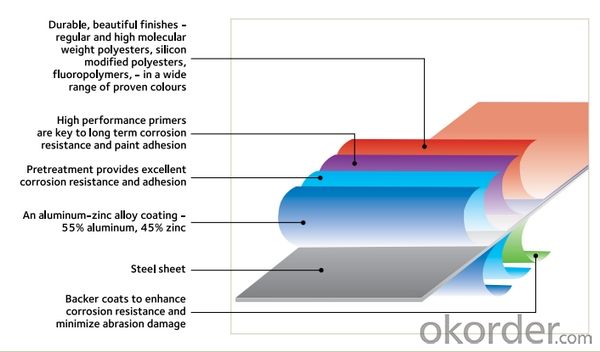

Structure of Al-Zinc coated steel coil

Description of Aluminum Zinc Rolled Coil

The detailed information for the Al-Zinc coated steel coil is as following and it is mainly using for roofing producing, making ceiling grid and all kinds of roll forming structure.

Thickness: 0.20mm to 1.20mm

Width: 914mm, 1000mm, 1200mm, 1219mm and 1250mm, or slit narrow strip according to customer request, can be slit from 20mm to 610mm.

Coil ID: 508mm

Coil weight: 3 tons to 6 tons

Thickness tolerance: +/- 0.02mm or according to customer request.

Main Feature of Al-Zinc coated steel coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Al-Zinc coated steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Al-Zinc coated steel coil

Prepainted galvanized steel coil ( PPGI ) | Prepainted galvalume steel coil ( PPGL ) | |

Standard | JIS G3312 CGCC | J IS G3322 CGLCC |

Valid thickness | 0. 16 ~1. 2 0mm | 0. 16 ~1. 2 0mm |

Coil width | 600~1250mm | 600~1250mm |

Coil ID | 508mm & 610mm | 508mm & 610mm |

Coil weight | 3~5 tons | 3~5 tons |

Coating | 4 0~275 g/m2 | AZ30 to AZ150 |

Paint t hickness , top side | 15~25 microns | 15~25 microns |

P aint t hickness , reverse | 5~7 microns or 15~25 microns | 5~7 microns or 15~25 microns |

Color | any RAL code | any RAL code |

Package | vertical, eye to sky & horizontal | vertical, eye to sky & horizontal |

MOQ | 25 tons | 25 tons |

FAQ of Al-Zinc coated steel coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How are steel coils used in the manufacturing of pipes?

- Steel coils are used in the manufacturing of pipes by being uncoiled, flattened, and then formed into a cylindrical shape through a process called pipe welding. The steel coils provide the necessary raw material for the production of pipes, ensuring strength, durability, and structural integrity.

- Q: 7850kg/cu.m density is typical for all type of steel? like reibar, I- beam and so on

- 90% of the steels used today are plain mild carbon steels consisting of iron with less than 1% carbon content and as such have a density of about 7750 kg/cubic meter. Some special steels which have a significant percentage of alloying elements such as chrome or manganese or other elements will have greater density bringing the steel up to about 8000 kg / cubic meter. There are a greater many factors influencing the exact density of a steel. Even for steels of exactly the same content of iron , carbon and other alloying elements, there may be a difference ( very small mind you ) in density due to work hardening. The difference in this case is due to movement of dislocations which become locked in the grain boundaries and this forms a more dense crystal structure. For this same reason, the theoretical density of steel (which does not take into account dislocations) is greater than the measured density of steel.

- Q: I have a new stainless steel trash compactor under a butcher block counter. We refinished the countertop, but unfortunately the person who did it wasn't careful with the orbital sander and sanded the top edge of the stainless steel compactor door, ruining the finish. The sander marks are not deep - just surface scratches - but they are unsightly. Is there any way to restore the finish to the stainless steel without having to buy a new door?

- Go over the entire surface with wet/dry sandpaper with the grain. Use wet with a little dish detergent. Remove the handles and name plates first. Start with 400, then 600, and then 800. Auto supply should sell the sandpaper. After final sanding, wax with carnuba wax and polish. Works on aluminum and real stainless not painted surfaces.

- Q: is cold roll or hot roll mill roller is cast steel? or cast iron?

- Casting is a process of forming a part just like forging or rolling are also processes of forming steel. Cast steel can be any grade of steel poured into a sand mold to form a part like a water pump housing in your car. To be classified as steel, the mixture usually contains less than 2% carbon. Cast iron is a mixture that generally contains more than 2% carbon. It also can be poured into a sand mold. There are many grades of iron. Many metals can be cast into shapes like the air intake plenum on your car is probably cast aluminum. Bronze statues are made by pouring molten bronze into a mold. The process used to create a part has an effect of that part's mechanical properties. A casting is weaker than a forging but certain parts cannot be formed by forging. The large diameter rolls used in steel mills to roll steel into thinner plates or sheets is a hot rolled steel that has probably been forged into shape then machined into the final diameter. Some rolls are fabricated from hot rolled steel plates into shape. This allows the ability to add internal cooling paths to keep the roll from overheating.

- Q: What is the role of steel coils in the manufacturing of bridges?

- Steel coils play a crucial role in the manufacturing of bridges as they are used to produce the beams and girders that provide the structural support and strength needed for the bridge. These coils are formed into various shapes and sizes, allowing for the customization required in bridge construction. Additionally, the high strength and durability of steel make it an ideal material for withstanding the heavy loads and harsh environmental conditions bridges are subjected to.

- Q: What are the different methods of forming steel coils?

- There are several methods used for forming steel coils, depending on the specific requirements and applications. These methods include hot rolling, cold rolling, and continuous casting. Hot rolling is the most common method used for forming steel coils. It involves heating the steel billet or ingot to high temperatures and then passing it between a series of rollers to reduce its thickness and shape it into a coil. This process is typically performed above the recrystallization temperature of the steel, which allows for better shaping and improved mechanical properties. Cold rolling, on the other hand, is a process that is performed at or near room temperature. It involves passing the steel through a series of rollers to reduce its thickness and shape it into a coil. Cold rolling is often employed to produce steel coils with precise dimensions and excellent surface finish. It can also increase the strength and hardness of the steel. Continuous casting is another method used for forming steel coils. It involves pouring molten steel into a continuous casting machine, where it is solidified into a strand. The strand is then continuously fed into a series of rollers, which shape it into a coil. Continuous casting offers several advantages, such as improved efficiency, reduced energy consumption, and better control over the steel's composition and quality. In addition to these primary methods, there are various secondary processes involved in forming steel coils. These include pickling, annealing, and coating. Pickling removes any rust or scale from the surface of the steel, ensuring a clean and smooth finish. Annealing involves heating the steel to a specific temperature and then slowly cooling it, which helps to improve its ductility and reduce internal stresses. Coating is often applied to steel coils to provide corrosion resistance or enhance its aesthetic appeal. In summary, the different methods of forming steel coils include hot rolling, cold rolling, and continuous casting. Each method offers unique advantages and is chosen based on the specific requirements of the steel product. Additionally, secondary processes such as pickling, annealing, and coating are often employed to further enhance the quality and performance of the steel coils.

- Q: What are the applications of steel coils in the aerospace industry?

- The aerospace industry relies heavily on steel coils for various purposes. One important application is in the manufacturing of aircraft structures. Steel coils are commonly used to fabricate wing spars, fuselage frames, and landing gear, as they possess high strength and durability necessary to withstand heavy loads and extreme conditions. Another significant use of steel coils in the aerospace industry is in the production of engine components, specifically turbine blades. These blades experience high temperatures and rotational forces, making it crucial to utilize steel coils due to their excellent heat resistance and mechanical properties. This ensures the reliability and performance of aircraft engines. Steel coils also find utilization in the production of fasteners and connectors necessary for securely joining different parts of an aircraft. Bolts, nuts, and rivets made from steel coils are essential for maintaining the structural integrity and safety of the aircraft. These fasteners need to possess high tensile strength and corrosion resistance. Furthermore, steel coils are employed in the production of fuel tanks and hydraulic systems. The weldability and formability of steel allow for the efficient fabrication of these complex structures. Steel coils can be shaped into various sizes and configurations, providing flexibility in designing fuel tanks and hydraulic components that meet specific requirements. In conclusion, steel coils are indispensable in the aerospace industry. Their use in aircraft structures, engine components, fasteners, and fuel tanks highlights their versatility and reliability. The exceptional strength, durability, heat resistance, and formability of steel make it the preferred material for various aerospace applications, ultimately ensuring the safety and performance of aircraft.

- Q: What are the different coil cutting machine options available for steel coils?

- There are several coil cutting machine options available for steel coils, including slitting machines, cut-to-length machines, and blanking machines. Slitting machines are used to cut the steel coils into narrower strips, while cut-to-length machines are designed to cut the coils into specific lengths. Blanking machines, on the other hand, are used to cut the steel coils into various shapes and sizes. These coil cutting machines offer different capabilities and can be chosen based on the specific requirements of the steel coil cutting process.

- Q: I've heard different things bout them, though I do not know this. Oh, and if you know where you can buy some raw or get custom made stuff out of black steel please let me know it would be greatly appreciated. Oh and my friend told me there is a black steel that can be sharpened and silver will be underneath, is this also true? Thank you very much for answering ^^

- My son is a bit and spur maker,I asked him about that and he told me that it is a tag they put on bits so a novice person will pay more for a bit that is not any better. Steel is Steel You should have a lot of bite with that bit because it is a pretty fine diameter. The black patina will wear off with use. BTW he just sent two silver bits to a big show in Reno Nev. I have not seen them or pictures of them but he has a $2,000 price tag on each of them. They must be real elaborate probably very fancy spade bits with highly engraved multicolored different metal butterflies on the ports.

- Q: What are the challenges in coil leveling for high-strength steel?

- Achieving optimal results in coil leveling for high-strength steel involves addressing several challenges. The steel's inherent hardness and strength present one of the main obstacles. High-strength steel is designed with enhanced mechanical properties, including tensile strength and hardness, making it difficult to deform and shape. To overcome the steel's high-strength nature, specialized leveling equipment is needed. This equipment must exert sufficient force to counter the steel's resistance to deformation. This may involve using stronger and more durable leveling rollers or increasing the pressure applied during the leveling process. Failing to apply the appropriate force can result in incomplete leveling, leading to residual stress and dimensional inaccuracies in the final product. Another challenge in coil leveling for high-strength steel is the potential for springback. Springback refers to the material's tendency to return to its original shape after being deformed. High-strength steel is especially prone to springback due to its higher elastic modulus. This can result in uneven leveling and dimensional variations in the coil. To mitigate springback, advanced leveling techniques can be utilized. These techniques include overbending and pre-bending the steel. Overbending involves bending the steel beyond the desired level, allowing it to spring back to the desired shape. Pre-bending, on the other hand, involves intentionally bending the steel in the opposite direction before leveling it, counteracting the effects of springback. These techniques require precise control and expertise to ensure accurate leveling. Additionally, high-strength steel often has a more pronounced yield point. The yield point is the stress level at which permanent deformation occurs. This can make it challenging to achieve consistent and uniform leveling throughout the coil. Proper adjustment of the leveling equipment and careful monitoring of the leveling process are necessary to effectively address this challenge. Furthermore, high-strength steel coils are often thinner and more sensitive to surface imperfections. Careful regulation of the leveling process is crucial to avoid causing damage to the steel surface, such as scratches or indentations. This may involve using softer leveling rollers or implementing protective measures, such as cushioning materials or coatings, to prevent surface defects. In summary, the challenges in coil leveling for high-strength steel revolve around its inherent hardness, springback tendencies, yield point behavior, and sensitivity to surface imperfections. Overcoming these challenges requires specialized equipment, advanced leveling techniques, precise control, and expertise to ensure accurate and high-quality leveling results.

Send your message to us

Al-Zinc Coated Steel Coil for construction roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords