Aluminum Foil Facing AL-PET Laminated Foil Composite for Shielding Coaxial Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Mylar foil Shielding Foil for Coaxial Cable communication cable

1.Structure of Aluminum Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Aluminum Mylar foil Shielding Foil:

Aluminum Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

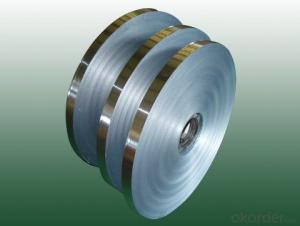

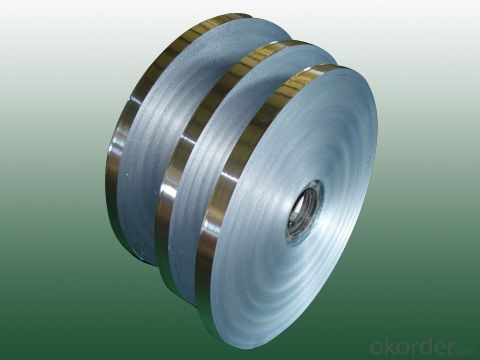

3. Aluminum Mylar foil Shielding Foil Images

4. Aluminum Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

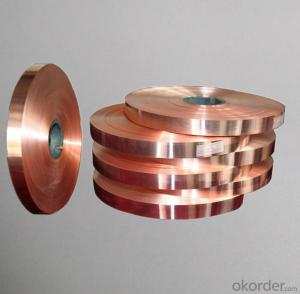

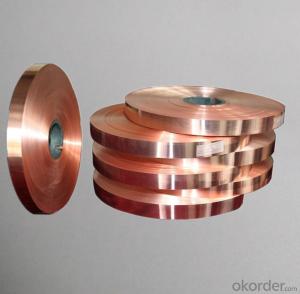

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Is it possible to use aluminum foil facing as a substitute for a pizza crust?

- <p>While it's not conventional, you can technically use aluminum foil facing as a makeshift pizza crust in a pinch. However, it won't provide the same texture or taste as a traditional crust. Aluminum foil is not designed for consumption and lacks the nutritional value of a real pizza crust. It's advisable to use a proper pizza dough or a store-bought crust for the best results. If you're in a bind, consider alternatives like using a tortilla or flatbread for a makeshift crust.</p>

- Q: What are the recommended cleaning products for aluminum foil facing after use?

- <p>For cleaning aluminum foil facing after use, it's best to use gentle, non-abrasive cleaning products. Mild dish soap and warm water are usually sufficient for most cleaning needs. Avoid using harsh chemicals or abrasive scrubbers, as they can damage the aluminum surface. If there are stubborn stains, a mixture of baking soda and water can be used as a gentle abrasive. Always rinse thoroughly and dry the surface to prevent any residue or potential damage.</p>

- Q: This question asks for a comparison of the pros and cons associated with the use of aluminum foil facing in construction or other applications.

- <p>Aluminum foil facing has several advantages, including excellent heat and cold insulation properties, which can significantly improve energy efficiency. It is also lightweight, making it easy to handle and install. The material is resistant to corrosion and has a long lifespan, reducing maintenance and replacement costs. Additionally, it provides a smooth, clean surface that is easy to clean and maintain. However, there are disadvantages such as its high cost compared to some alternatives, which can be a barrier for some projects. It can also be damaged by sharp objects, which may compromise its integrity. Lastly, while it reflects heat, it can also reflect sound, potentially leading to acoustic issues in some environments.</p>

- Q: This question asks for methods to prevent aluminum from aluminum foil leaching into food.

- <p>To avoid aluminum from aluminum foil leaching into your food, use the foil sparingly and avoid wrapping food directly in it. Opt for heavy-duty aluminum foil, which is less likely to tear and expose food to aluminum. When cooking acidic or salty foods, consider using parchment paper or silicone baking mats as alternatives. Additionally, avoid using aluminum foil at high temperatures, as this can increase the risk of aluminum transfer. Finally, store food in glass or stainless steel containers instead of aluminum foil to minimize exposure.</p>

- Q: What are the eco-friendly options available to replace plastic containers?

- <p>Yes, there are several alternatives to plastic containers that are more environmentally friendly. Glass containers are a popular choice due to their durability and ability to be reused multiple times. Stainless steel containers are also a great option as they are long-lasting and do not leach chemicals. Biodegradable materials like bamboo, silicone, and certain types of plant-based plastics are other alternatives. Additionally, using cloth bags or reusable food wraps can help reduce the need for single-use plastic containers.</p>

- Q: This question asks for the most effective methods to utilize aluminum foil when preparing food for freezing or frying, specifically focusing on the aluminum foil facing.

- <p>Aluminum foil facing is best used for preparing food for freezing or frying by ensuring even heat distribution and maintaining food's moisture. For freezing, line your baking sheet with aluminum foil facing down to prevent sticking and make removal easier. When freezing individual portions, wrap them tightly in foil to protect their shape. For frying, use foil to create a barrier between the food and direct heat, which can help in even cooking. Always make sure the foil is shiny side out for better heat reflection and椋熷搧瀹夊叏. Remember to avoid overheating as aluminum foil can melt at high temperatures.</p>

- Q: What are the primary applications or purposes of aluminum foil facing in various industries or everyday life?

- <p>Aluminum foil facing is primarily used for its heat reflective properties, making it ideal for insulation in construction and roofing. It also serves as a moisture barrier and vapor barrier in walls and ceilings, helping to prevent mold and mildew. In the HVAC industry, it's used for duct insulation, enhancing energy efficiency. Additionally, it's utilized in packaging for food and pharmaceuticals to protect contents from light, air, and moisture, thus preserving freshness and quality.</p>

- Q: This question asks for advice on how to use aluminum foil effectively in the kitchen.

- <p>Using aluminum foil efficiently in the kitchen can save time and resources. Here are some tips: 1. Pre-cut and store: Keep a roll of aluminum foil in the kitchen and pre-cut pieces for quick use. 2. Double layer for insulation: Use a double layer for wrapping food to retain heat and keep food warm for longer. 3. Line baking sheets: Line baking sheets with foil to prevent sticking and make cleanup easier. 4. Cover dishes: Use foil to cover dishes in the oven to prevent over-browning. 5. Use for grilling: Wrap vegetables or fish in foil for easy, mess-free grilling. 6. Reuse: Reuse aluminum foil for multiple tasks to minimize waste. 7. Avoid overuse: Use only as much foil as needed to prevent unnecessary waste. 8. Recycle: Always recycle aluminum foil after use to contribute to sustainability.</p>

- Q: Is it safe and effective to use aluminum foil with a reflective side to wrap vegetables when grilling?

- <p>Yes, you can use aluminum foil facing to wrap vegetables for grilling. Aluminum foil helps to retain moisture and heat, ensuring that the vegetables cook evenly and remain tender. The reflective side of the foil can also help to distribute heat more evenly. However, be cautious not to let the foil touch the flame directly, as it can cause flare-ups. Make sure to poke some holes in the foil to allow steam to escape and prevent the vegetables from becoming too soggy.</p>

- Q: Is it possible to use aluminum foil with a shiny side facing up as a liner for a baking pan?

- <p>Yes, you can use aluminum foil facing as a baking pan liner. The shiny side of the aluminum foil is non-stick and can be used to line baking pans, making it easier to remove baked goods without sticking. Ensure the foil is heavy-duty to withstand high temperatures and prevent tearing. However, avoid using it for direct contact with acidic or alkaline foods, as the foil may react with them. Always follow the manufacturer's guidelines for safe use.</p>

Send your message to us

Aluminum Foil Facing AL-PET Laminated Foil Composite for Shielding Coaxial Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords