Aluminum Foil Facing Laminated Foil Shielding Foil for Coaxial Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Mylar foil Shielding Foil for Coaxial Cable communication cable

1.Structure of Aluminum Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Aluminum Mylar foil Shielding Foil:

Aluminum Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

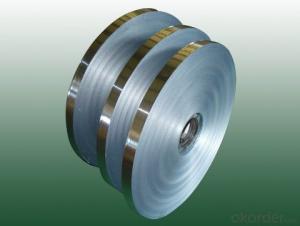

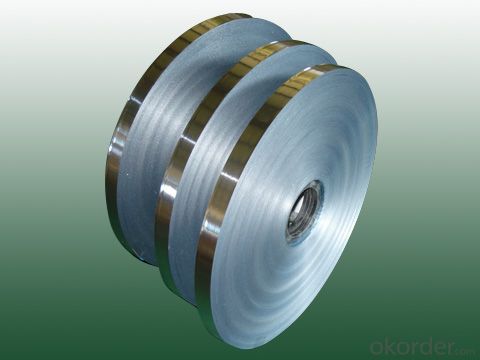

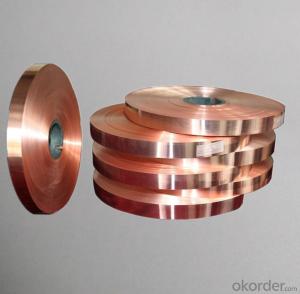

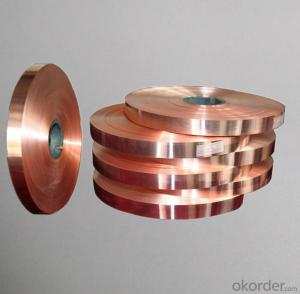

3. Aluminum Mylar foil Shielding Foil Images

4. Aluminum Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: This question asks for methods to clean aluminum foil facing that has old food stains on it after cooking.

- <p>To remove old food stains from aluminum foil facing, start by scraping off any loose debris with a spatula or scraper. Then, soak the stained area in warm soapy water for about 15 minutes. Use a soft cloth or sponge to gently scrub the stains. For stubborn stains, make a paste of baking soda and water, apply it to the stain, and let it sit for a few hours before scrubbing. Rinse thoroughly with water. If stains persist, consider using a non-abrasive cleaner specifically designed for aluminum surfaces. Always test any cleaning solution on a small, inconspicuous area first to ensure it doesn't damage the surface.</p>

- Q: What are the methods to ensure food does not adhere to aluminum foil while baking?

- <p>To prevent food from sticking to aluminum foil when baking, you can use a few methods. First, lightly grease the foil with cooking spray or oil before placing food on it. Second, consider using a non-stick spray or a light brushing of butter or oil directly on the food itself. Another option is to use parchment paper as a barrier between the food and the foil. Additionally, ensure the food is not overcooked, as this can cause it to stick. Lastly, avoid using shiny, new aluminum foil for acidic or sugary foods as it may react with the foil.</p>

- Q: Is it possible for metal shavings to contaminate food when using aluminum foil with a shiny side?

- <p>There is minimal risk of metal shavings getting into food when using aluminum foil facing. Aluminum foil is designed to be safe for food contact and is generally resistant to shedding particles. However, if the foil is damaged or handled roughly, small particles could potentially come off. To mitigate this risk, ensure the foil is in good condition, avoid tearing it, and handle it carefully to prevent any metal contamination.</p>

- Q: This question asks for guidance on preparing a nutritious meal using aluminum foil as a cooking method.

- <p>To make a healthy meal using aluminum foil, consider 'foil packet cooking'. Choose lean protein like chicken or fish, and pair it with a variety of colorful vegetables such as bell peppers, zucchini, and cherry tomatoes. Season with herbs, garlic, and a drizzle of olive oil. Fold the foil to create a sealed packet and bake in the oven at 400掳F (200掳C) for about 20-25 minutes or until the protein is cooked through and the vegetables are tender. This method retains nutrients and flavors while minimizing added fats.</p>

- Q: What are the most effective ways to clean surfaces that have aluminum foil applied to them?

- <p>The best cleaning methods for aluminum foil facing involve gentle cleaning to avoid damaging the foil. Use a soft cloth or sponge with warm water and mild dish soap to wipe the surface. Avoid abrasive cleaners or scrubbing, as this can scratch or tear the foil. For stubborn stains, a mixture of baking soda and water can be applied as a paste and gently rubbed with a soft cloth. Always rinse thoroughly and dry the surface to prevent water spots and maintain the integrity of the aluminum foil.</p>

- Q: Explain the distinctions between aluminum foil facing and plastic wrap, including their composition, uses, and properties.

- <p>Aluminum foil facing is a thin layer of aluminum used for insulation, moisture protection, and as a barrier to light and air. It is commonly used in construction and food packaging for its heat and cold resistance. Plastic wrap, on the other hand, is made from plastic polymers like polyethylene and is primarily used for food storage, keeping food fresh by sealing in moisture and preventing contamination. Unlike aluminum foil, plastic wrap is transparent, clingy, and does not conduct heat, making it unsuitable for cooking or insulation purposes.</p>

- Q: Is it safe to use pre-cut sheets of aluminum foil for cooking or baking purposes?

- <p>Yes, it is generally safe to use pre-cut sheets of aluminum foil for cooking and baking. Aluminum foil is designed to withstand high temperatures and is commonly used to cover food, line baking sheets, or wrap food for cooking. However, it's important to ensure that the foil does not come into direct contact with the heating element of an oven, as this can cause it to melt or create a fire hazard. Additionally, avoid using aluminum foil with non-stick cookware, as it can damage the non-stick surface. Always follow the manufacturer's guidelines for safe use of aluminum foil in your specific cooking appliances.</p>

- Q: What are the unique cleaning techniques for maintaining aluminum foil facing surfaces?

- <p>Aluminum foil facing requires gentle cleaning to avoid scratching the surface. Use a soft cloth or sponge with warm water and mild dish soap to clean the surface. Avoid abrasive materials like steel wool or harsh chemicals, as they can damage the aluminum. After cleaning, dry the surface thoroughly to prevent water spots. For stubborn stains, a mixture of water and white vinegar can be used, but always test on a small, inconspicuous area first. Regular cleaning will help maintain the appearance and functionality of aluminum foil facing.</p>

- Q: This question asks for a list of various types of aluminum foil facing that can be found in the market.

- <p>There are several types of aluminum foil facing available in the market today, including: 1. Standard Aluminum Foil Facing, which is the most common type used for insulation and moisture protection. 2. Reinforced Aluminum Foil Facing, which is stronger and more durable, often used in high-temperature applications. 3. Embossed Aluminum Foil Facing, which has a textured surface for improved aesthetics and grip. 4. Coated Aluminum Foil Facing, which is coated with materials like polyethylene for added protection against chemicals or moisture. 5. Perforated Aluminum Foil Facing, which has small holes for ventilation or drainage. 6. Laminated Aluminum Foil Facing, which combines aluminum with other materials for enhanced properties. These types cater to various applications in construction, food packaging, and other industries.</p>

- Q: Is it safe to use old aluminum foil for food packaging, considering potential health risks and material degradation?

- <p>Using old aluminum foil for food packaging is not recommended. Over time, aluminum foil can become discolored, thin, or develop pinholes, which can compromise its integrity. These changes can lead to food contamination and the foil's ability to protect food from bacteria or other contaminants. Additionally, old aluminum foil may contain residues from previous uses that could mix with new food items, potentially causing off-flavors or health concerns. It's best to use fresh, clean aluminum foil for food packaging to ensure safety and hygiene.</p>

Send your message to us

Aluminum Foil Facing Laminated Foil Shielding Foil for Coaxial Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords