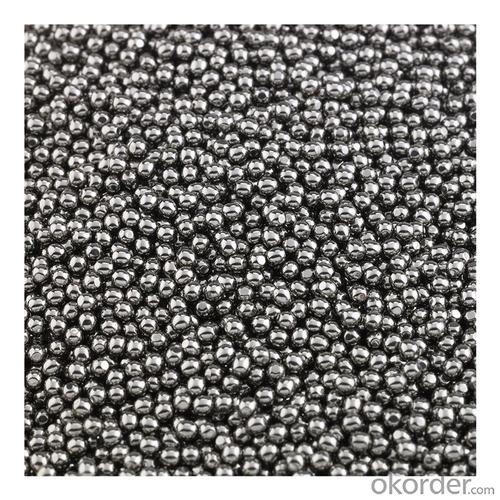

AISI420 Steel Shot All Sizes G100 Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

THE DETAIL OF STAINLESS STEEL BALL

| Product | Stainless steel ball |

| Material | stainless steel |

| Brand | SAIGE |

| Percision | G100 |

| Hardness | HRC>52 |

| Surface | zero defect, bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Package | four small boxes within a carton of 20kg |

| Certification | ISO9100;2008SGS |

Stainless steel (AISI 420)

AISI 420 have good hardness and fair-to-good corrosion resistance and strength, it is generally used for all applications requiring resistance to corrosion such as bearings, valves, writting instruments, food environment, fresh water, many petroleum products and mild acid environments. AISI 420 is also magnetic.

AISI 420 stainless steel balls in our factory:

Minimum diameter :1.2mm

Best precision :G10

Hardness :HRc>52

THE ADVENTAGE OF STAINLESS STEEL BALL

A, The strict process of stainless steel ball

Raw material--Wire drawing--Cold heading--Flashing--Heat treament--Grinding--Lapping 1--Lapping2--Lapping3--Washing--Checking. All balls must be passed the procedure of passivation. Each procedure have professional inspector. They will check steel balls each two hours to be sure correct diameter and good surface.

B, Sample Free

If you are interested in our product ,we can send you our free sample for you . Please contact us as soon as possible.

SAFE PACKAGE

Step 1: Weighing stainless steel balls. Usually the weight is about 10kg.

Step 2: Sealed plastic bags

Step 3: Put sealed plastic bags into small boxes.

Step 4: Each box has the label, including material, Lot No. Size, quantity, grade, date and so on

Step 5: Each box directly put into mooden case.

High precision stainless steel balls usually is oil package. Normal precision stainless steel balls usually is dry package.

We also can pack them according to customers' request.

- Q: What are the different types of steel products used in the manufacturing of electronics?

- Some of the different types of steel products used in the manufacturing of electronics include stainless steel, carbon steel, and electrical steel. Stainless steel is commonly used for components that require corrosion resistance, such as enclosures and connectors. Carbon steel is used for structural components and fasteners due to its strength and affordability. Electrical steel, also known as silicon steel, is used for laminations in transformers and motors due to its magnetic properties.

- Q: What are the different types of steel sheets and their uses in the packaging industry?

- There are several types of steel sheets used in the packaging industry, including tinplate, galvanized steel, and stainless steel. Tinplate is a thin steel sheet coated with a layer of tin, making it highly resistant to corrosion. It is commonly used for making food cans and beverage containers due to its ability to preserve the contents' freshness. Galvanized steel sheets are coated with a layer of zinc, which provides excellent rust resistance. They are often utilized for packaging materials that require durability and strength, such as metal drums and pails. Stainless steel sheets, known for their corrosion resistance and hygienic properties, are used in the packaging industry for applications like pharmaceutical packaging, cosmetic containers, and high-end food packaging.

- Q: How is steel plate formed into seamless pipes?

- Steel plate is formed into seamless pipes through a process called piercing and rolling. In this process, the steel plate is first heated and then pierced to create a hollow tube. The pierced tube is then elongated and shaped using a series of rollers to achieve the desired dimensions and thickness. This seamless pipe manufacturing method ensures a uniform and continuous structure without any welded seams.

- Q: What are the advantages of using steel products in the automotive industry?

- There are several advantages of using steel products in the automotive industry. Firstly, steel is a highly durable and strong material, providing robustness and ensuring safety in the event of accidents or collisions. Secondly, steel is readily available and cost-effective, making it a cost-efficient choice for automakers. Additionally, steel is easily recyclable, contributing to sustainability efforts and reducing the environmental impact of the automotive industry. Lastly, steel's versatility allows for various shapes and sizes, accommodating the diverse design requirements of different vehicle components. Overall, the use of steel products in the automotive industry offers durability, cost-effectiveness, sustainability, and design flexibility.

- Q: How is steel used in the production of agricultural machinery?

- Steel is used in the production of agricultural machinery for its durability and strength. It is commonly used to construct the main frames, parts, and components of these machines, providing the necessary support and resistance to the heavy loads and harsh operating conditions commonly encountered in farming.

- Q: What are the different types of steel bolts and their uses in the automotive aftermarket?

- There are several different types of steel bolts commonly used in the automotive aftermarket. Some of the most common types include hex bolts, flange bolts, carriage bolts, and socket head cap bolts. Hex bolts are the most widely used type of bolt and are typically used for general-purpose applications. They have a hexagonal head and require a wrench or socket for tightening. Flange bolts have a built-in washer under the head, which helps distribute the load and provide a more secure connection. These bolts are often used in applications where vibration or movement is a concern. Carriage bolts have a round, domed head and a square or ribbed neck under the head. They are commonly used in applications where a smooth finish is desired, such as attaching decorative accessories or trim. Socket head cap bolts have a cylindrical head with a socket drive and are commonly used in applications where a low-profile, flush finish is desired. These bolts are often used in engine components, suspension systems, and other areas where space is limited. Each type of steel bolt has its own specific uses in the automotive aftermarket, depending on factors such as load requirements, vibration resistance, and desired finish. It is important to choose the appropriate type of bolt for each application to ensure proper functionality and safety.

- Q: How do steel products contribute to the construction of zoos and wildlife sanctuaries?

- Steel products contribute to the construction of zoos and wildlife sanctuaries in various ways. Firstly, steel is a durable and strong material that is used to create the framework and support structures of zoo exhibits and enclosures, ensuring the safety and security of the animals. Additionally, steel is used in the construction of visitor facilities like walkways, observation decks, and viewing platforms, allowing visitors to safely observe and interact with the animals. Steel products also play a crucial role in the creation of gates, fences, and barriers, helping to keep the animals secure and prevent any unwanted interactions. Overall, steel products provide the necessary strength, stability, and versatility required for the construction of zoos and wildlife sanctuaries.

- Q: How does steel tube bending work?

- Steel tube bending works by applying force to a straight steel tube to deform it into a desired curved shape. This force is typically exerted through a combination of heat and mechanical pressure, which softens the steel and allows it to be bent without breaking. Different methods, such as mandrel bending or induction bending, are used depending on the size and thickness of the tube.

- Q: What are the challenges faced in the welding of steel products?

- There are several challenges faced in the welding of steel products. One of the main challenges is the potential for distortion or warping of the steel during the welding process. Steel has a high thermal conductivity, which means it can quickly absorb and distribute heat. This can lead to uneven heating and cooling, causing the metal to deform. Another challenge is the presence of impurities and contaminants on the surface of the steel, such as rust, oil, or paint. These impurities can negatively affect the quality of the weld and make it more difficult to achieve proper fusion. Additionally, the high carbon content in some types of steel can make it more prone to cracking and brittleness during the welding process. Proper pre-cleaning, selection of appropriate welding techniques, and careful control of heat input are crucial in overcoming these challenges and producing high-quality welded steel products.

- Q: What are the advantages of using steel in the construction of sports stadiums?

- There are several advantages of using steel in the construction of sports stadiums. Firstly, steel is a durable and strong material, which provides the necessary structural integrity and stability required for large-scale constructions like stadiums. Secondly, steel is highly versatile and allows for creative and innovative architectural designs. It can be easily shaped and manipulated to create unique and visually appealing structures. Additionally, steel is a cost-effective option as it is readily available and can be prefabricated off-site, reducing construction time and labor costs. Lastly, steel is also a sustainable choice as it is recyclable, minimizing waste and environmental impact.

Send your message to us

AISI420 Steel Shot All Sizes G100 Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords