AISI420 All Sizes Steel Shot Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

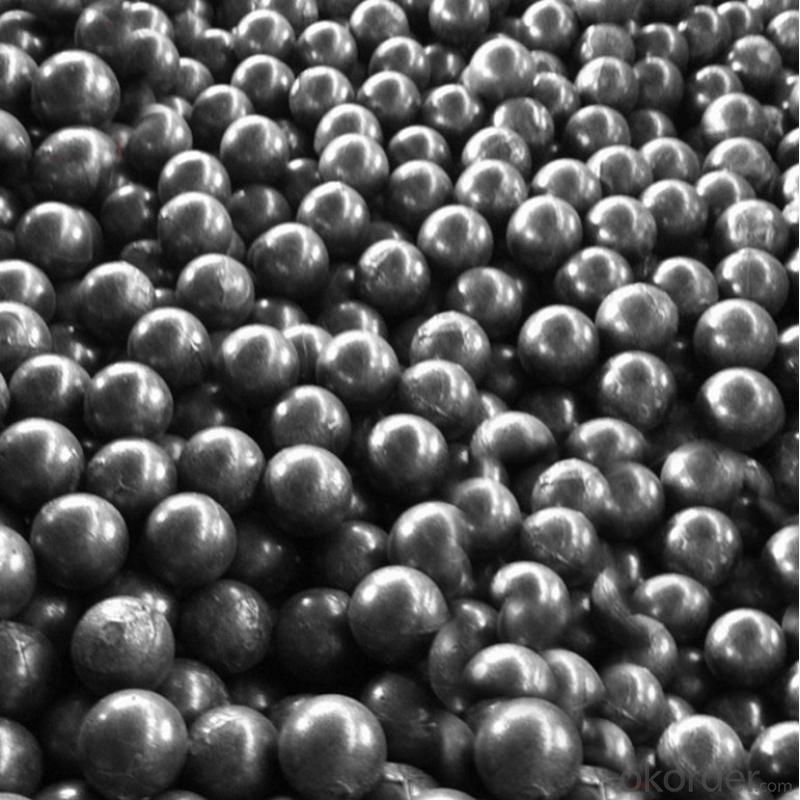

Products Picture

| Product | AISI420 G100 All Sizes Steel Shot Stainless Steel Ball |

| Material | stainless steel |

| Pericision | G100 |

| Hardness | HRC25-39 |

| Surface | zero defect , bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Safe | ROHS |

| Package | four small boxes within a carton of20kg |

Expect the stainless steel ball , we have other steel balls . carbon steel ball , chorme steel ball .

Strict peocess

our company have the strict process :Raw material--Wire drawing--Cold heading--Flashing--Heat treatment--Grinding--Lapping1--Lapping2--Lapping3--Washing--Checking--Packing

High efficiency / High efficiency inspection

Our production capacity is 160 tons per month. we have the high quality testing instruments

for example : roundness measuring equipment , photometric sorter, metallographic structure detector, vibroscope,salt spray tester.

Green product

Our company product are all passed the ISO and SGS certification .

Competitive price: We are a direct steel ball manufacture, lower price is possible

Advanced production flow: With our more than 20 years experience, we have explored compelete production flow, high quality has become an advantage.

- Q: How is steel used in the energy sector, such as in power plants?

- Steel is widely used in the energy sector, particularly in power plants, due to its strength, durability, and heat resistance properties. It is used for constructing power plant infrastructure, such as the supporting framework, turbine components, boilers, and pipelines. Steel is also used in the manufacturing of power transmission towers and electrical transformers. Its versatility and ability to withstand high temperatures make it a crucial material in the energy sector.

- Q: How are steel products used in the railway industry?

- Steel products are extensively used in the railway industry for various applications. Steel is commonly used for manufacturing railway tracks, train wheels, and various structural components of the railway infrastructure. Additionally, steel is used in the construction of railway cars, locomotives, and various equipment such as bridges, tunnels, and signaling systems. Its high strength, durability, and ability to withstand heavy loads make steel an ideal material for ensuring the safety and efficiency of the railway system.

- Q: How is steel used in the construction of bridges?

- Steel is commonly used in the construction of bridges due to its strength and durability. It is used to create the framework and support structures of the bridge, providing stability and the ability to withstand heavy loads. Steel is also used for the fabrication of girders, beams, and columns, which form the main components of the bridge's superstructure. Additionally, steel is often utilized for the construction of cables and suspension systems in suspension bridges, ensuring their strength and flexibility. Overall, steel plays a crucial role in bridge construction, offering the necessary strength and resilience to ensure the safety and longevity of these vital infrastructures.

- Q: How is steel tubing used in manufacturing?

- Steel tubing is used in manufacturing for various applications such as structural support, conveyance of fluids and gases, and as a component in machinery and equipment. It provides strength, durability, and flexibility, making it ideal for constructing frameworks, pipelines, and automotive parts. Its versatility and wide range of sizes and shapes make it an essential material in the manufacturing industry.

- Q: How are steel products used in the manufacturing of consumer goods?

- Steel products are used in the manufacturing of consumer goods in various ways, such as in the production of appliances like refrigerators, washing machines, and ovens, as well as in the construction of automobiles, bicycles, and furniture. Steel's durability, strength, and versatility make it an ideal material for these applications, providing stability, safety, and longevity to the final products.

- Q: How is steel used in the construction of theme parks and recreational facilities?

- Steel is a crucial material in the construction of theme parks and recreational facilities due to its strength, durability, and versatility. It is used for various structural elements such as roller coaster tracks, support beams, and framework for large-scale attractions. Steel's ability to withstand heavy loads and extreme weather conditions ensures the safety and stability of these structures, making it an essential component in creating thrilling and engaging experiences for visitors.

- Q: How is steel used in the construction of sports stadiums and arenas?

- Steel is used extensively in the construction of sports stadiums and arenas due to its strength, durability, and versatility. It is used to create the framework and support structure of the building, including the roof, columns, beams, and trusses. Steel allows for large, open spaces without the need for excessive support columns, providing unobstructed views for spectators. Additionally, steel is used in the construction of seating areas, staircases, and walkways, ensuring safety and stability. Overall, steel plays a crucial role in creating the impressive and functional structures necessary for modern sports venues.

- Q: What are the different types of steel products used in the manufacturing of educational toys?

- There are several different types of steel products that are commonly used in the manufacturing of educational toys. Some of these include stainless steel, which is often used for the construction of durable and long-lasting toy parts. Carbon steel is another commonly used steel product, known for its strength and versatility, which makes it suitable for various toy components. Additionally, galvanized steel may be used to provide corrosion resistance, ensuring the toys remain in good condition for a longer duration.

- Q: What are the different types of steel bridges and structures available?

- There are several types of steel bridges and structures available, including truss bridges, arch bridges, suspension bridges, cable-stayed bridges, and girder bridges. Each type has its own unique design and construction method, suited for specific span lengths and load requirements.

- Q: What are the different types of steel tanks and their applications in the chemical industry?

- There are several different types of steel tanks commonly used in the chemical industry, each with its own specific applications. Some of the most common types include carbon steel tanks, stainless steel tanks, and alloy steel tanks. Carbon steel tanks are widely used due to their affordability and strength. They are suitable for storing non-corrosive chemicals and are often used for petroleum products, water, and certain acids. Stainless steel tanks are known for their superior corrosion resistance and durability. They are commonly used for storing corrosive chemicals, such as acids, alkalis, and solvents. These tanks are also suitable for hygienic applications in the food and pharmaceutical industries. Alloy steel tanks are designed to withstand high pressures and temperatures. They are often used for storing reactive chemicals, such as hydrogen, ammonia, and chlorine. These tanks are also used in processes that require high strength and resistance to corrosion. Overall, the choice of steel tank in the chemical industry depends on the specific application, the properties of the chemicals being stored, and the required levels of corrosion resistance, strength, and durability.

Send your message to us

AISI420 All Sizes Steel Shot Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords