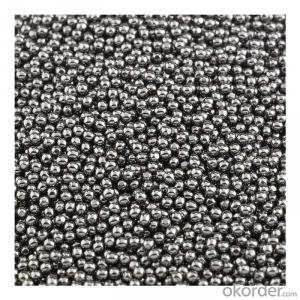

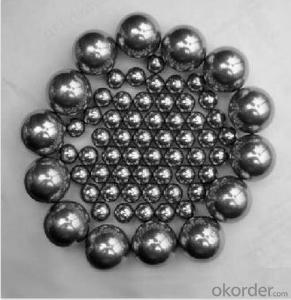

G100 6mm Steel Shot Used Chemcial Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

G100

Certification:

ISO

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

20kg/bag

Packaging:

Standard Export Packing

Hereare many kinds of stainless steel balls, AISI 304, AISI 316, AISI 316L, AISI 420, AISI 420C,

AISI 440, AISI 440C.AISI 304 steel ballshave no good hardness but offer good corrosion resistance,

they offer good resistance to atomospheric corrosion, dyes, food processing, valves, sex products and so on.

AISI 304 stainless steel ball in our factory :

Minimum diameter: 2mm

Best precision :G100

Hardness :HRc25-39

| Product | G100 6mm Steel Shot Used Chemcial Stainless Steel Ball |

| Material | stainless steel |

| Test | SGS |

| Percision | G100 |

| Hardness | HRC25-39 |

| Surface | zerodefect, bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Package | four small boxes within a carton of 20kg |

| Materials Standard | Chemical Composition (%) | Hardness | ||||||

| JIS SUS304 (AISI304) (Din X5CrNi18-10) | C | Cr | Ni | Si | Mn | P | S | HRC25-39 |

| <0.08 | 18.00-20.00 | 8.00-10.50 | <1.0 | <2.0 | <0.045 | <0.030 | ||

The adventage of AISI304 stianless steel ball

A, Safe Package

Step 1: Weighing stainless steel balls. Usually the weight is about 10kg.

Step 2: Sealed plastic bags

Step 3: Put sealed plastic bags into small boxes.

Step 4: Each box has the label, including material, Lot No. Size, quantity, grade, date and so on

Step 5: Each box directly put into mooden case.

High precision stainless steel balls usually is oil package. Normal precision stainless steel balls usually is dry package.

We also can pack them according to customers' request.

B,Sample free

If you are interested in our product , we can send you our free sample for you . Please contact us as soon as possible.

- Q: What are the different types of steel storage racks?

- There are several different types of steel storage racks, including pallet racks, cantilever racks, drive-in racks, push-back racks, and flow racks. Each type is designed for specific storage needs and offers unique benefits and features.

- Q: How is steel pipe threaded for plumbing applications?

- Steel pipe is threaded for plumbing applications using a process called threading, which involves cutting helical grooves or ridges on the external surface of the pipe. This is typically achieved using a threading machine or a die set. The threaded ends of the pipe can then be connected to fittings, allowing for a secure and leak-resistant plumbing system.

- Q: How are steel gratings used in the construction of walkways and platforms?

- Steel gratings are used in the construction of walkways and platforms to provide a strong and durable surface for people to walk on. They are designed with an open grid pattern, allowing for easy passage of air, light, and water, while providing sufficient grip and stability. These gratings are installed on the framework of the walkway or platform, creating a safe and secure footing for pedestrians, even in wet or slippery conditions. Additionally, steel gratings are resistant to corrosion and can withstand heavy loads, making them ideal for high-traffic areas in construction projects.

- Q: How is steel used in the construction of bridges?

- Steel is commonly used in the construction of bridges due to its high strength and durability. It is used in the fabrication of beams, girders, and trusses, providing crucial support and load-bearing capacity. Steel's flexibility allows for the creation of various bridge designs, including arches, suspension, and cable-stayed bridges. Additionally, steel's corrosion resistance and ability to withstand extreme weather conditions make it an ideal material for bridge construction, ensuring the longevity and safety of these vital structures.

- Q: What are the applications of steel forgings in aerospace?

- Steel forgings have a wide range of applications in aerospace due to their high strength, durability, and reliability. They are commonly used in critical components such as landing gear, engine parts, turbine discs, and structural elements. Steel forgings provide the necessary strength-to-weight ratio and resistance to fatigue and impact that are essential for ensuring the safety and performance of aircraft in demanding operational conditions.

- Q: What are the different types of steel forgings and their applications in the construction of power transmission lines?

- There are several different types of steel forgings commonly used in the construction of power transmission lines. These include: 1. Anchor shackles: These forgings are used to secure the guy wires, which provide stability to the transmission towers. 2. Clevises: Clevis forgings are used in the construction of suspension insulator assemblies, which connect the transmission wires to the towers. 3. Eye bolts: Eye bolts are used to attach various hardware components to the transmission towers, such as grounding equipment or insulator strings. 4. Yoke plates: Yoke plates are used in the construction of tension insulator assemblies, which help distribute the weight and tension of the transmission wires. 5. Pole line hardware: This category includes various steel forgings such as pole bands, brackets, and clamps, which are used to secure the transmission towers to the poles. Overall, steel forgings play a crucial role in the construction of power transmission lines by providing strength, durability, and reliable connections between various components.

- Q: What is the process of galvanizing steel?

- The process of galvanizing steel involves coating it with a layer of zinc to protect it from corrosion. This is done by first cleaning the steel surface to remove any impurities. Then, the steel is dipped into a bath of molten zinc or electroplated with zinc. The zinc bonds with the surface of the steel, creating a protective layer that prevents rust and extends the lifespan of the steel.

- Q: What are the different types of steel bridges and structures available?

- There are several types of steel bridges and structures available, including truss bridges, arch bridges, suspension bridges, cable-stayed bridges, and girder bridges. Each type has its own unique design and construction method, suited for specific span lengths and load requirements.

- Q: What are the applications of steel mesh in security fencing?

- Steel mesh is commonly used in security fencing applications due to its high strength and durability. It provides a secure barrier that prevents unauthorized entry and acts as a deterrent to potential intruders. Steel mesh also allows for visibility, making it suitable for areas that require constant monitoring. Additionally, its versatility and customizable design make it ideal for various security applications such as protecting commercial properties, residential areas, prisons, airports, and construction sites.

- Q: What role do steel products play in the energy and power generation sector?

- Steel products play a crucial role in the energy and power generation sector as they are extensively used in various applications. Steel is used to construct power plants, including thermal, nuclear, and hydroelectric facilities, providing the structural support needed for large-scale infrastructure. Additionally, steel is used in the manufacturing of turbines, generators, transmission towers, and pipelines, ensuring efficient energy generation, transmission, and distribution. Its durability, strength, and resistance to extreme conditions make steel products indispensable in the energy and power generation sector.

Send your message to us

G100 6mm Steel Shot Used Chemcial Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords