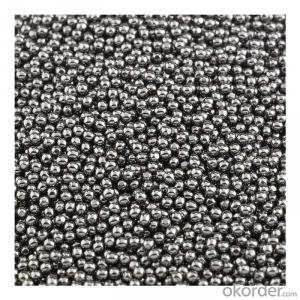

Chrome Steel Ball (G10) /52100 Balls/Bearing Ball/Steel Shot/Stainless Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Hot Rolled,Cold Rolled

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

g10

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

20kg/bag

Packaging:

Standard Export Packing

Our company is a professional AISI 52100 15.875mm-150mm G10-GG1000 chrome steel ball manufacturer for more than two decades. Before reformation, it is the joint venture with LYC.

Production procession

According to the ISO9001, we have established the strict & perfect quality assurance system, making sure that the whole production process is controlled and steady quality is offered to satisfy customers.

Composition of Different Materials

| Material | Chemical of Different Materals | ||||||||

| C | SI | Mn | P | S | Ni | Gr | Mo | Cu | |

| AISI440C | 0.95-1.20 | 1.00max | 1.00max | 0.040max | 0.030max | 0.60max | 16.00-18.00 | 0.75max | _ |

| AISI420C | 0.42-0.50 | 1.00max | 1.00max | 0.040ax | 0.030max | 1.00max | 12.5-14.5 | _ | 0.30max |

| AISI304 | 0.08max | 1.00max | 2.00max | 0.045max | 0.030max | 8.00-10.5 | 18.00-20.00 | _ | _ |

| AISI316 | 0.08max | 1.00max | 2.00max | 0.045max | 0.030max | 10.00-14.00 | 16.00-18.00 | 2.00-3.00 | _ |

| AISI E52100&GC r15 | 0.95-1.10 | 0.95-1.10 | 0.50max | 0.025max | 0.025max | _ | 1.30-1.60 | _ | _ |

Applications:

Chrome steel balls are applied in bearings such as slew bearing, deep groove ball bearing, thrust ball bearing, self aligning ball bearing, double-row bearing and etc.

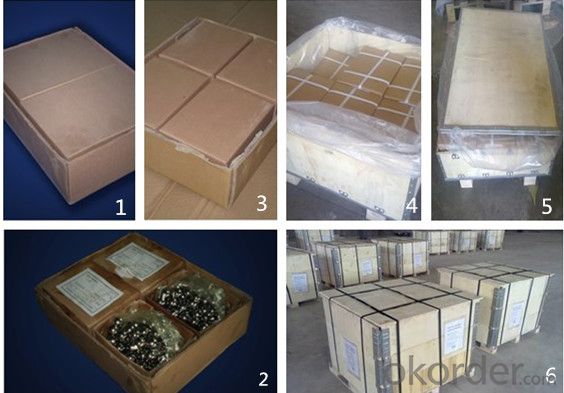

Packing:

Carton box by wonden plates

our products are very well known in more than European and other foreign countries. your cooperation and order are warmly welcome!

- Q: What are the properties of heat-treated steel?

- Heat-treated steel has several properties that make it desirable for various applications. These properties include increased hardness, improved strength and toughness, enhanced wear resistance, and better dimensional stability. Heat treatment alters the microstructure of the steel by heating it to a specific temperature and then cooling it rapidly or slowly, depending on the desired outcome. This process can result in the formation of important phases like martensite, which contributes to the steel's hardness and strength. Overall, heat-treated steel exhibits excellent mechanical properties, making it suitable for applications where durability and strength are crucial, such as in the automotive, aerospace, and construction industries.

- Q: How is carbon steel different from stainless steel?

- Carbon steel and stainless steel are both alloys of iron, but they differ in their composition and properties. Carbon steel contains a higher amount of carbon, making it more susceptible to corrosion and rust. On the other hand, stainless steel contains a higher amount of chromium, which forms a passive oxide layer that protects it from corrosion. This makes stainless steel more resistant to rust and staining than carbon steel. Additionally, stainless steel has a higher tensile strength and is more durable, while carbon steel is typically less expensive and more malleable.

- Q: How are steel profiles used in the fabrication of storage racks?

- Steel profiles are commonly used in the fabrication of storage racks due to their strength and durability. These profiles serve as the main structural components, forming the framework for the racks. They are cut, shaped, and welded together to create sturdy shelves and supports, ensuring the racks can withstand the weight of various items being stored. Additionally, steel profiles can be easily customized to accommodate different storage needs, such as adjustable shelving or specialized racks for specific products.

- Q: How are steel products used in the construction of public transportation systems?

- Steel products are used extensively in the construction of public transportation systems due to their strength, durability, and versatility. Steel is commonly utilized for the structural framework of bridges, tunnels, railway tracks, and elevated platforms, ensuring the infrastructure can withstand heavy loads and constant use. Additionally, steel is used in the manufacturing of train and subway cars, providing a safe and reliable means of transportation for the public.

- Q: How is steel rebar used in concrete construction?

- Steel rebar is used in concrete construction to provide reinforcement and strength to the concrete structures. It is typically placed within the concrete forms before pouring, forming a framework that helps to distribute the load and prevent cracking or failure. The rebar enhances the tensile strength of the concrete, allowing it to withstand greater forces and improve the overall durability and longevity of the structure.

- Q: What are the applications of steel forgings?

- Steel forgings have a wide range of applications in various industries, including automotive, aerospace, construction, and oil and gas. They are commonly used for manufacturing components that require high strength, durability, and resistance to wear and tear. Some specific applications include crankshafts, gears, axles, connecting rods, turbine blades, and structural components in buildings and bridges.

- Q: What are the environmental impacts of producing steel products?

- The environmental impacts of producing steel products include emissions of greenhouse gases during the production process, such as carbon dioxide and methane. Steel production also contributes to air pollution through the release of particulate matter, sulfur dioxide, and nitrogen oxides. The extraction of raw materials for steel production, such as iron ore and coal, can result in habitat destruction and deforestation. Additionally, the energy-intensive nature of steel manufacturing leads to significant consumption of natural resources, including water and energy. Proper management and implementation of sustainable practices are crucial to minimize these environmental impacts.

- Q: How do steel products contribute to the construction of research laboratories and scientific facilities?

- Steel products play a crucial role in the construction of research laboratories and scientific facilities. They provide structural support and durability, ensuring the safety and integrity of the buildings. Steel beams, columns, and frames are commonly used to create large open spaces, allowing for flexible layouts and accommodating various equipment and machinery. Additionally, steel is resistant to fire, corrosion, and pests, making it an ideal choice for laboratories where hazardous materials and sensitive experiments are conducted. Overall, steel products are essential components in creating efficient, functional, and secure research facilities.

- Q: What are the advantages of using steel in the manufacturing of tanks and vessels?

- There are several advantages of using steel in the manufacturing of tanks and vessels. Firstly, steel is known for its exceptional strength and durability, making it highly resistant to corrosion and damage from external factors. This ensures the longevity of tanks and vessels, reducing the need for frequent repairs or replacements. Additionally, steel's high tensile strength allows for the construction of tanks and vessels with thinner walls, maximizing storage capacity while maintaining structural integrity. Moreover, steel is a versatile material that can be easily formed into various shapes and sizes, allowing for customization and efficient use of space. Lastly, steel is a cost-effective option due to its availability, recyclability, and low maintenance requirements, making it a preferred choice for the manufacturing of tanks and vessels.

- Q: What are the different types of steel sheets and their uses in the construction of prefabricated buildings?

- There are several types of steel sheets used in the construction of prefabricated buildings. One common type is hot-rolled steel sheets, which are known for their strength and durability. These sheets are often used in the construction of structural components such as beams, columns, and trusses. Another type is cold-rolled steel sheets, which are typically thinner and more precise in dimension. They are commonly used for cladding and roofing purposes. Galvanized steel sheets are coated with a layer of zinc to enhance their resistance to corrosion, making them suitable for outdoor applications. Lastly, stainless steel sheets are highly resistant to rust and corrosion, making them ideal for areas with high moisture or chemical exposure. These sheets are often used in kitchens, bathrooms, and other areas that require a hygienic and durable surface. Overall, the different types of steel sheets serve various purposes in the construction of prefabricated buildings, ensuring structural integrity, durability, and aesthetics.

Send your message to us

Chrome Steel Ball (G10) /52100 Balls/Bearing Ball/Steel Shot/Stainless Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords