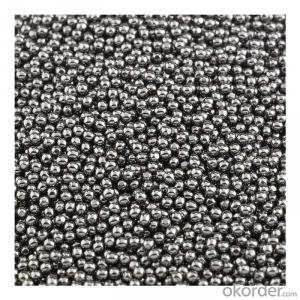

SUS420 G100 8mm Metal Balls RoHS Stainless Steel Shot Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

| Product | AISI420 G100 All Sizes Steel Shot Stainless Steel Ball |

| Material | stainless steel |

| Pericision | G100 |

| Hardness | HRC25-39 |

| Surface | zero defect , bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Safe | ROHS |

| Package | four small boxes within a carton of 20kg |

Products Picture

Strict process

our company have the strict process :Raw material--Wire drawing--Cold heading--Flashing--Heat treatment--Grinding--Lapping1--Lapping2--Lapping3--Washing--Checking--Packing

High efficiency / High efficiency inspection

Our production capacity is 160 tons per month. we have the high quality testing instruments

for example : roundness measuring equipment , photometric sorter, metallographic structure detector, vibroscope,salt spray tester.

Green product

Our company product are all passed the ISO and SGS certification .

Competitive price: We are a direct steel ball manufacture, lower price is possible

Advanced production flow: With our more than 20 years experience, we have explored compelete production flow, high quality has become an advantage.

Discount: Since we are steel ball foctory, we would like larger quantity, so we will provide suitable discount according to your quantity.

- Q: What are the different types of steel sections used in industrial structures?

- There are several types of steel sections commonly used in industrial structures, including I-beams, H-beams, channels, angles, and T-sections. These sections are chosen based on their structural properties, such as load-bearing capacity and resistance to bending. Each section has its own unique shape and dimensions, allowing for efficient distribution of weight and optimal structural integrity in various applications.

- Q: How are steel products used in the construction of residential buildings and housing complexes?

- Steel products are extensively used in the construction of residential buildings and housing complexes due to their strength, durability, and versatility. They are commonly employed in the structural framework, such as beams, columns, and trusses, providing a sturdy and stable support system. Steel is also used for reinforcing concrete, increasing the strength and resistance of the building against various forces. Additionally, steel is utilized in the construction of roofing systems, wall panels, stairs, and balconies, offering aesthetic appeal and long-lasting performance. Overall, steel products play a crucial role in ensuring the safety, stability, and longevity of residential buildings and housing complexes.

- Q: What are the applications of steel in the wastewater treatment industry?

- Steel is widely used in the wastewater treatment industry for various applications. It is used to construct tanks and vessels that hold wastewater, as steel is highly durable, corrosion-resistant, and can withstand harsh environmental conditions. Steel is also used in the construction of piping systems, pumps, and valves, ensuring efficient transportation and control of wastewater. Additionally, steel is employed in the manufacturing of screening and filtration equipment, which helps remove solid waste from wastewater. Overall, the applications of steel in the wastewater treatment industry contribute to the effectiveness and longevity of the treatment processes.

- Q: How are steel pipes used in the transportation of chemicals?

- Steel pipes are commonly used in the transportation of chemicals due to their high strength and durability. They are designed to withstand the corrosive nature of many chemicals and can safely transport them over long distances. The smooth interior surface of steel pipes also helps to minimize friction and maintain the purity of the chemicals being transported. Additionally, steel pipes can be easily connected and installed, making them a reliable choice for the transportation of chemicals in various industries.

- Q: What are the different types of steel valves?

- There are several types of steel valves, including gate valves, globe valves, ball valves, check valves, butterfly valves, and needle valves. Each type has its own unique design and functionality, catering to specific applications and industries.

- Q: What are the different types of steel hinges and hardware available?

- There are several different types of steel hinges and hardware available, including butt hinges, continuous hinges, piano hinges, strap hinges, pivot hinges, gate hinges, and cabinet hinges. Each type of hinge has its own unique design and functionality, making it suitable for specific applications and requirements. Additionally, there are various hardware options such as screws, bolts, latches, handles, and brackets that complement the hinges and provide additional support and functionality.

- Q: What are the advantages of using steel in automotive manufacturing?

- There are several advantages to using steel in automotive manufacturing. Firstly, steel is a strong and durable material, providing excellent structural integrity and enhancing the overall safety of vehicles. Additionally, steel is readily available and cost-effective, making it a cost-efficient choice for mass production. Moreover, steel can be easily shaped and molded, allowing for complex designs and customization options. Lastly, steel has a high melting point and is resistant to extreme temperatures, ensuring the longevity and reliability of automotive components.

- Q: What are the different types of steel channels and their uses?

- There are several types of steel channels, including C channels, U channels, and J channels. C channels are commonly used in construction for structural support, while U channels are often used for framing and reinforcement in manufacturing and automotive industries. J channels are typically used for trim or edging purposes, such as finishing off the edges of siding or paneling. Overall, steel channels are versatile and widely used in various applications due to their strength and durability.

- Q: How are steel products used in the agricultural sector?

- Steel products are widely used in the agricultural sector for various applications. They are used to manufacture equipment such as tractors, plows, and harvesters, which are essential for farming operations. Steel is also used in constructing storage facilities like barns and silos, providing durability and strength to protect crops and livestock. Additionally, steel is used in fencing and irrigation systems, providing a strong and reliable infrastructure for agricultural operations. Overall, steel products play a crucial role in enhancing efficiency and productivity in the agricultural sector.

- Q: What are the applications of steel forgings in the defense industry?

- Steel forgings have various applications in the defense industry due to their exceptional strength, durability, and performance under extreme conditions. They are commonly used in the manufacturing of critical components such as artillery shells, tank tracks, missile bodies, aircraft landing gear, and structural parts for military vehicles and ships. Steel forgings offer superior mechanical properties, resistance to wear and corrosion, and can withstand high temperatures and pressures, making them ideal for enhancing the reliability and effectiveness of defense equipment in combat scenarios.

Send your message to us

SUS420 G100 8mm Metal Balls RoHS Stainless Steel Shot Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords