Adhesive Back Aluminum Oxide Sheets - AA3105 Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheets AA3105 Used for Constrcution Description

Aluminum Sheets AA3105 Used for Constrcutionare widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

Direct Continuous Aluminium Foil Stock in Coil is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of Aluminum Sheets AA3105 Used for Constrcution

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

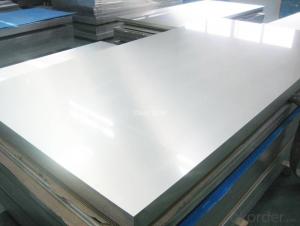

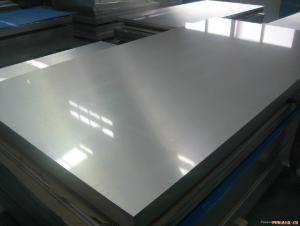

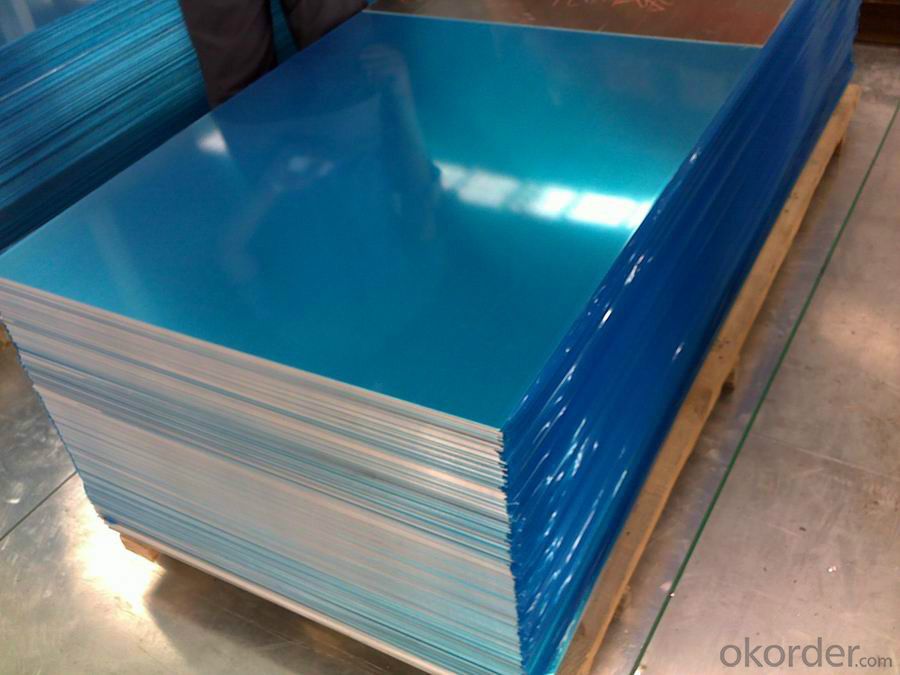

3.Aluminum Sheets AA3105 Used for Constrcution Images

4.Aluminum Sheets AA3105 Used for Constrcution Specification

Alloy | AA3105 |

Temper | H14, H16, H18, H22 |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN |

5. FAQ of Aluminum Sheets AA3105 Used for Constrcution

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA3105 Used for Constrcution.

B.

What is the quality standard?

---Usually our standard is GB3880-2006

C. What is the largest width?

---It is 2300mm

- Q: Are aluminum sheets suitable for electrical busbars?

- Yes, aluminum sheets can be suitable for electrical busbars. Aluminum is a widely used material in the electrical industry due to its excellent electrical conductivity, lightweight nature, and affordability compared to other metals like copper. Aluminum sheets can be easily fabricated into the desired shape and size required for busbars, making them a versatile choice for electrical applications. Additionally, aluminum has good thermal conductivity, which helps in dissipating heat generated during electrical operations. However, it is important to note that aluminum has a lower electrical conductivity compared to copper, so it may require larger cross-sectional areas to achieve the same electrical performance. It is essential to consider the specific requirements of the electrical system and consult with experts to determine if aluminum sheets are suitable for a particular busbar application.

- Q: What is the typical machinability of aluminum sheets?

- Aluminum sheets are widely acknowledged for their excellent machinability. This is due to their relatively low density and softness, which make them easier to machine compared to other metals. Furthermore, aluminum exhibits good thermal conductivity, enabling efficient heat removal during machining. Its low melting point also reduces the likelihood of overheating. Moreover, aluminum demonstrates favorable chip formation characteristics, resulting in effortless chip removal and decreased tool wear. However, the machinability of aluminum may differ depending on factors like alloy composition, tempering, and surface finish. Nevertheless, aluminum sheets are generally considered to be highly machinable.

- Q: Can aluminum sheets be used for insulation cladding?

- Yes, aluminum sheets can be used for insulation cladding. Aluminum is a popular choice for cladding material due to its durability, lightweight nature, and resistance to corrosion. It acts as a protective layer for insulation materials, providing thermal insulation, weather resistance, and aesthetic appeal to buildings.

- Q: Is it possible to use aluminum sheets for constructing a sustainable building?

- <p>Yes, aluminum sheets can be used to create a sustainable building due to their recyclability, low thermal conductivity, and durability. Aluminum is a lightweight material that can reduce the energy consumption in transportation and construction. It also has a high recycled content ratio and can be easily recycled, which reduces waste. Additionally, aluminum's low thermal conductivity can contribute to energy efficiency in buildings by reducing heat transfer, thus lowering energy costs for heating and cooling. However, it's important to consider the entire life cycle of the material and ensure that the manufacturing and disposal processes align with sustainable practices.</p>

- Q: Do 101 aluminum sheets have any specific certifications or standards?

- Yes, 101 aluminum sheets typically have certifications and standards that ensure their quality and performance. These may include certifications like ASTM (American Society for Testing and Materials) and standards such as AA (Aluminum Association) standards, which verify the material's composition, mechanical properties, and manufacturing processes. Additionally, specific industry certifications like ISO 9001 (International Organization for Standardization) may be applicable to ensure consistent quality control during production.

- Q: How do you prevent warping of aluminum sheets during machining?

- One way to prevent warping of aluminum sheets during machining is by using proper coolant or lubricants during the machining process. This helps in reducing the friction and heat generated, which can cause warping. Additionally, maintaining correct cutting speeds and feeds, as well as ensuring proper tool selection and machining techniques, can also help minimize the chances of warping.

- Q: Wonderland is the hard aluminum with what tools do? Thank you

- Wrought iron platform made 3 aluminum alloy with a hard aluminumAluminum + granite can also be synthesized

- Q: If something is wrong, what kind of glue can be used for bonding the stainless steel sheet and aluminum sheet? The area may be very big. What are some common or good glue to buy?

- Stainless steel plate and aluminum plate usually use acrylic structure glue.Acrylic structural adhesive two-component acrylate modified by synthesis and curing agent structural adhesive composition, A, B two agents are 100% solid components; fast curing, high strength, about 5 minutes to 30 minutes after the initial fixation strength up to 80%, 24 hours after the maximum strength; excellent resistance to acid and alkali, water, oil medium, high temperature resistance, better aging properties of metal items between strong adhesion, resistance strength is better than that of epoxy resin, excellent resistance to thermal shock, working at -30~150 DEG C; compliance with international environmental standards, has passed the European ROSH standard.

- Q: Is it possible to apply paint to an aluminum sheet roof after it has been installed?

- <p>Yes, you can paint your aluminum sheet roof after installation. However, it's crucial to ensure the surface is clean and free of any contaminants. Use a primer specifically designed for aluminum to enhance adhesion and durability. Apply a high-quality paint suitable for metal surfaces, following the manufacturer's instructions carefully. This process can help protect the roof from weathering and enhance its appearance, but it's recommended to consult with a professional to ensure the best results and longevity of the paint job.</p>

- Q: Can aluminum sheets be used for electrical enclosures?

- Yes, aluminum sheets can be used for electrical enclosures. Aluminum is a popular choice for electrical enclosures due to its excellent conductivity, corrosion resistance, and lightweight properties. It is a good conductor of electricity, allowing for efficient distribution of electrical current within the enclosure. Additionally, aluminum has a high resistance to corrosion, making it suitable for outdoor and harsh environment applications. Its lightweight nature also makes it easier to handle and install. Overall, aluminum sheets are a reliable and commonly used material for electrical enclosures.

Send your message to us

Adhesive Back Aluminum Oxide Sheets - AA3105 Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords