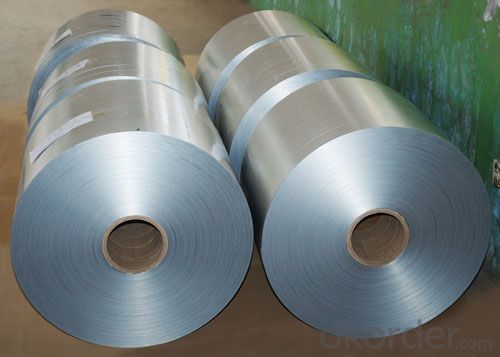

Acrylic Brand Aluminum Coil - 2a12 5052 5083 6061 6083 7075 Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

2a12 5052 5083 6061 6083 7075 Aluminum Sheet

Packaging & Delivery

| Packaging Details: | Standard seaworthy packages in bundles or as per requirement. Container size: The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 4 0ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM(stainless steel seamless pipe) |

| Delivery Detail: | Within 5-15 days after deposit(price of aluminum coil) |

Our Services

1. Provide products with high quality and reasonable price

2. The first time back to you

3. Perfect after-sale service

4. Small order is acceptable

5. OEM is acceptable

6. 12Months quality guarantee

7. Any third party testing is acceptable

Product Description

| Product Name | Prices of aluminum coil |

| Standard | JIS, AISI, ASTM, GB, DIN |

| Alloy | Yes |

| Width | 720-1250mm or as the customers' requirements |

| Length | 10000-12000mm mm or as the customers' requirements |

| Thickness | 0.12-1.5mm |

| Surface | Black painted,PE coated,GL,color coated,etc |

| Item | steel plate,steel sheet,alloy plate,alloy sheet |

| Application | construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields ,etc. |

| Packing | Export standard or as customers' requirement |

| Delivery time | Within 7 working days, according to customers' quantities |

| Payment | L/C or T/T or as customers' requirement |

| MOQ | 1 Ton |

| Quality | High Quality. We can Provide SGS inspection if you need . |

| Productivity | 60000 Tons/Month |

| Attention | We will supply you good quality and bottom price and first-class service in china and hope to be your golden supplier |

- Q: Can aluminum coils be used in the production of aluminum composite ceilings?

- Yes, aluminum coils can be used in the production of aluminum composite ceilings. Aluminum coils are commonly used as the base material for manufacturing aluminum composite panels, which are then used in various applications including ceilings. The coils are processed and coated to meet the desired specifications and aesthetics of the composite ceiling panels.

- Q: Can aluminum coils be used in the production of aluminum composite walls?

- Aluminum composite walls can utilize aluminum coils for production purposes. To construct these walls, a layer of polyethylene is typically sandwiched between two aluminum sheets. Initially, the aluminum coils undergo processing to transform into flat aluminum sheets, which then function as the outer layers of the composite wall. During the manufacturing process, the coils are unravelled and flattened to achieve the desired width and thickness of the aluminum sheets. These sheets possess superior strength, durability, and resistance to weather conditions, making them an ideal choice for aluminum composite walls. Moreover, the utilization of aluminum coils enables efficient and cost-effective production since they can be easily processed and moulded into the required dimensions.

- Q: Are aluminum coils suitable for solar panel frames?

- Yes, aluminum coils are suitable for solar panel frames. Aluminum is a lightweight and corrosion-resistant material, making it ideal for use in solar panel frames. It is also highly durable and can withstand various weather conditions, ensuring the longevity of the solar panel structure. Additionally, aluminum is easy to work with and offers excellent heat dissipation properties, which is crucial for solar panels as they generate heat during operation. The use of aluminum coils in solar panel frames helps to enhance the overall efficiency and performance of the solar panel system.

- Q: What are aluminum coils used for?

- Aluminum coils are commonly used in various industries, such as construction, automotive, and HVAC, for their excellent thermal conductivity and corrosion resistance properties. They are primarily used for manufacturing heat exchangers, air conditioning systems, refrigeration units, and other heat transfer applications.

- Q: This question asks for the cost of an aluminum coil, which can vary based on factors such as weight, quality, and market conditions.

- <p>The cost of an aluminum coil can vary significantly based on its weight, grade, and current market prices. As of my last update, the price per pound can range from about $0.30 to $1.50, but this is subject to change with market fluctuations. For precise pricing, it's best to check with a supplier or on a commodity exchange, as aluminum prices are dynamic and influenced by global supply and demand.</p>

- Q: How do aluminum coils contribute to lightweight vehicle design?

- Aluminum coils play a crucial role in achieving lightweight vehicle designs due to their unique properties and manufacturing processes. Aluminum is a lightweight material itself, weighing about one-third of the weight of steel, making it an ideal choice for lightweight vehicle design. When aluminum is formed into coils, it provides several benefits that contribute to the overall weight reduction of the vehicle. Firstly, aluminum coils are highly formable, allowing complex shapes to be achieved using less material. This property enables automakers to design intricate body panels and structural components that are not only lightweight but also offer improved aerodynamics and fuel efficiency. The ability to form aluminum coils into intricate shapes also allows for increased design flexibility, leading to more innovative and visually appealing vehicle designs. Secondly, aluminum coils offer exceptional strength-to-weight ratio, making them an excellent choice for structural components. Despite being lightweight, aluminum coils provide excellent structural integrity, ensuring the vehicle's safety and durability. By incorporating aluminum coils into the vehicle's chassis, suspension systems, and other critical components, automakers can reduce weight while maintaining the necessary strength and rigidity required for safe operation. Furthermore, aluminum coils have excellent corrosion resistance, which is essential for the longevity of the vehicle. Corrosion can significantly impact a vehicle's structural integrity and overall performance. By using aluminum coils, automakers can reduce the risk of corrosion-related issues, leading to longer lifespan and reduced maintenance costs. Lastly, the use of aluminum coils helps in reducing the overall weight of the vehicle, resulting in improved fuel efficiency and reduced greenhouse gas emissions. Lighter vehicles require less energy to accelerate and maintain speed, leading to better fuel economy. This benefit is increasingly important as the automotive industry focuses on developing more sustainable and eco-friendly vehicles. In conclusion, aluminum coils contribute significantly to lightweight vehicle design by offering high formability, exceptional strength-to-weight ratio, corrosion resistance, and overall weight reduction. These properties enable automakers to design vehicles that are not only lighter but also safer, more fuel-efficient, and visually appealing. As the demand for lightweight vehicles increases, aluminum coils play a vital role in achieving these design goals.

- Q: I've heard many times that it's unhealthy to store or cook food in aluminum, due to leaching, but will this apply to handling aluminum. Also, I heard that most aluminum is coated with a layer of something, to prevent oxidation; is this true?

- Pure soft shiny aluminum develops a thin tenacious layer of aluminum oxide that retards further oxidation (unless worn off). The outer layer of skin is dead horny matter that resists penetration by metal atoms. However, some people do develop allergies to metals and perhaps metals dissolved in sweat (acids?) may get through to live tissue. Handling aluminum may not have been proved harmful but skeptics likely will take less chances.

- Q: How are aluminum coils shipped and transported?

- Aluminum coils are typically shipped and transported in a variety of ways, depending on their size, weight, and destination. Here are a few common methods: 1. Flatbed Trucks: For shorter distances or when shipping smaller aluminum coils, flatbed trucks are commonly used. The coils are securely loaded onto the flatbed and secured with straps or chains to prevent movement during transportation. 2. Intermodal Containers: When shipping aluminum coils over longer distances, intermodal containers are often used. These containers can be loaded onto trucks, trains, or ships, making them a versatile option. The coils are typically stacked and secured inside the container using bracing or blocking materials to prevent shifting. 3. Rail Transport: Aluminum coils can also be transported by rail, especially for longer distances. Coils are loaded onto flatcars or specialized coil cars that have built-in cradles or bolsters to securely hold the coils in place during transit. 4. Vessels: When shipping aluminum coils internationally or to distant locations, they are often transported by sea using cargo vessels. Coils are carefully loaded into the vessel's cargo hold and secured with lashings or other securing methods to prevent movement and damage during the voyage. Regardless of the transportation method chosen, it is crucial to ensure that the aluminum coils are adequately protected from moisture, dust, and other potential sources of damage during transit. Packaging materials such as moisture-resistant wrapping, protective covers, or crates are used to safeguard the coils and maintain their quality until they reach their destination.

- Q: need to know the procedure for removal of aluminum windows with brick trim

- 1st off let`s determine what kind of windows you have. Examine the inside of the jambs. Are there any screws going through the jamb into the rough opening? If so you have a masonary style window. Chances are they can be removed relatively easily. Most the time removal of fastners,scoring of drywall and caulk and they practically fall out (sometimes). You may find removal of the sash and remaining glass, then collasping the frame will work best. This technique is a must if you have the other breed of window, the flanged. You can ID this window by measuring the inside and out . If they`re the same, it`s flanged. I`ve found 99 time out of 100 these windows can be collasped. Once again remove sash and all glass. Here`s where the sawsall comes in. Remove the center bar. Drive a flat bar under the sill from the exterior. Pry it up as high as you can. Cut the sill. Now drive the flat bar between the side jambs and the brick and start prying. Most of the time these windows are only nailed on the corners, sometimes the fin will rip from the jamb. But in the end the removal will be accomplished. If you find you need to pry from the interior, don`t pry against drywall. Put a piece of wood under your bar to protect the drywall. NEVER! pry on tile or marble. I`ve removed literally thousands of these little buggers. Can`t only remember maybe a handful of times I had to cut a flange. GOOD LUCK!!!!!

- Q: Can aluminum coils be used in automotive heat shields?

- Indeed, automotive heat shields can utilize aluminum coils. Thanks to its exceptional resistance to heat and lightweight characteristics, aluminum is extensively employed in heat shield production. By shaping and forming aluminum coils according to the desired design, automotive applications can benefit from straightforward installation and customization. Moreover, the high thermal conductivity of aluminum aids in efficiently dissipating heat, rendering it an optimal option for vehicle heat shields.

Send your message to us

Acrylic Brand Aluminum Coil - 2a12 5052 5083 6061 6083 7075 Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords