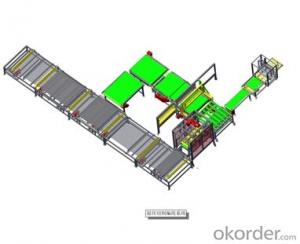

ACC Panel production line with Capacity of 100,000m3

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Our AAC plant adopts Germany technology.

Capacity: 100,000m3-300,000m3

Full automation or Semi automation

high quality

We produce 4.0m, 4.2m, 4.8m, and 6m series of high capacity AAC production line for Middle East, Africa and South-east of Asia, etc. The Whole set of Aerated-Concrete equipment we produced have become universal products for domestic new or existing aerated factories. AAC blocks will become dominate wall materials in future.

Application Scope: AAC block producing

Feature

The operation of our plant is simple and pratical.

Waste materials and water can be recycled during operation process, it is environment-friendly.

The whole equipment has higher degree of automation.

The final products are high in precision, qualified product rate ≥ 98%.

Our AAC plant has good cost performance.

Production Process:

1.Stocking and supplying raw materials

2.Processing raw materials

3.Batching and pouring

4.Cutting

5.Grouping and maintaining process

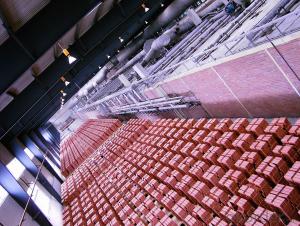

6.Steaming in autoclaves

7.Final products packaging

Product Principle

1) Technology Orientation

Production and application of aerated concrete has a history more than 40 years in China. Viewing from technology point, high quality products can use 3mm special sand slurry technology to meet the construction requests and 50% energy saving goals. (When mortar joint is less than 3mm, take thermal conductivity coefficient of wall as 1; when mortar joint is more than 3mm, take thermal conductivity coefficient of wall as 1.5). Based on the history of the aerated concrete development, only high quality products can bring a prosperous market. Thus, the technology orientation of this scheme is high-class products according to China Standard GB11968-2006.

2) Production Capacity

In our factory, the main production capacity is annually 50,000m3, 100,000m3, 150,000m3, 200,000m3, 300,000m3 etc. The product is aerated concrete block which is light in weight. Also, there is a reservation of plate in consideration of users' need.

3) Product Specification

Products conform to requirement of 04~07 grade blocks stated in GB11968-2006.

General Specifications of Aerated Concrete Blocks

Service

1.Production Line Design.

Including: drawing of plant working process , drawings of land construction, drawings of power working, drawings of driving force for working, drawings of anti-dust, drawings of water supply and drainage, and drawing of air pipeline construction.

2.Technical Guidance of Building Factory

Including: consultation of facility, Equipment installation guide, constitution the production preparation, etc.

3.Providing the technical information of setting up factory

Including: part of the factory management system, all posts accountability of production line, process rules, safety rules, setting a quota of staff and posts, pre-production tools directory, laboratory instruments, product catalogs, and test methods.

FAQ:

1. Where is your factory located?

Our factory is located in Jiangsu Province. It is close to Shanghai Port.

2. What are your advantages compared with others?

CNBM is the largest manufacturer and supplier of building materials and machinery in China. We are directly under control of State-owned Assets Supervision and Administration Commission of China. We have more 20 engineers who are engage in quality inspection, and more than 50 employees who are in charge of logistic. Our products are manufactured under ISO quality control system.

3. Which countries does your plant export to?

Our production line has been installed in the Middle East, Africa. India and so on.

- Q: Brief introduction of the brick machine

- The hydraulic control device comprises a fuel tank and a motor pump, the motor pump and the fuel tank are connected through the tubing and horizontally on the main engine frame. Hydraulic control device can be manually operated hydraulic drive system or equipped with electronic numerical control device CNC automatic control system.

- Q: Cement brick machine brick machine advantages

- Cement hollow brick machine is the production of brick-free brick brick machine, is the production of brick can not be used.

- Q: Maintenance method of fly ash brick machine

- the quality of personnel to participate in maintenance is low, can not follow the maintenance of the operating procedures, there is no corresponding maintenance records.

- Q: Where is the brick of the tiles used to make the brick better?

- Its role: 1, with good water permeability, breathability, can quickly penetrate the rain, add soil water and groundwater, to maintain soil moisture, improve the urban ground plants and soil microbial living conditions.

- Q: Installation and commissioning of hydraulic press

- 1, check the brick machine in the transport process is damaged or deformation (especially pay attention to hydraulic pipe).

- Q: How can a free brick brick brick machine be classified?

- According to the structure of the block: divided into a back cover block, not the back of the block, slot block, a slot block.

- Q: The scope of application of building waste brick machine

- Concrete tiles made of construction waste, the strength is higher than the national standard of 20%. With the construction waste by the brick machine can be made sidewalk brick, brick walls, construction waste made of brick prices significantly lower than the clay brick, effectively saving land resources. To build waste brick as the starting point, you can vigorously develop new wall materials, and actively promote the industrial structure of building materials adjustment.

- Q: What is the difference between a vacuum brick machine and an ordinary brick machine?

- Vacuum brick machine than an ordinary brick machine more than a vacuum equipment, in general, ordinary brick machine can only produce standard bricks, vacuum brick extruded brick moisture content than ordinary brick machine out of the low, speed up the production cycle.

- Q: Hollow block brick brick machinery in use should pay attention to what the problem to ensure the normal operation of the brick machine?

- New, old mold, be sure to avoid collision, bump, civilized assembly, pay attention to protect the mold;

- Q: Free burning brick brick brick machine can be how to classify

- According to the use of functions: divided into ordinary blocks, decorative blocks, insulation blocks, sound-absorbing blocks and other types.

Send your message to us

ACC Panel production line with Capacity of 100,000m3

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches