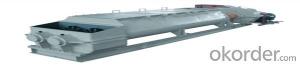

Roller crusher of brick making production line with best quality and excellent price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Roller crusher is mainly used to crush the raw materials such as gangue, industial waste, clay and other materials. It is an ideal raw material handling machine.The rollers of GS120X120 and GS120x100 are imported from Germany to increase service life.

Technical parameters:

Production capacity (m3/h): ≥45

Inlet grain hardness (Moh’s hardness): ≤4

Water content of inlet material: ≤16%

- Q: Fly ash Mianshao brick machine is not a kind of construction waste with coal ash to do brick, who understand this thing?

- Mainly used to suppress the fly ash, sand, sand, sand, slag, slag as the main raw material of Mianshaozhuan, steamed sand bricks, refractory bricks and hollow brick production, is the country strongly advocated environmentally friendly Building materials equipment.

- Q: Burning brick and autoclaved lime sand brick what different

- Also known as aerated blocks, aerated bricks, mainly used for high-rise building filling, do the wall. The size of the brick can be combined with the need to cut.

- Q: Brief introduction of the brick machine

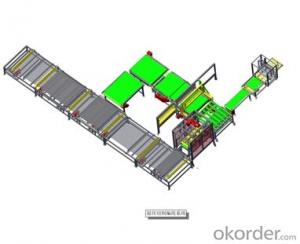

- The purpose of the utility model is to realize an integrated hydraulic brick making machine comprising a main engine, an automatic conveying device, a hydraulic control device, a hopper, a hydraulic platform, a mixer, a hydraulic pallet conveyor, a pallet box, Valve handle, mold sets, die indenter, raw material hydraulic conveyor, pallet.

- Q: What are the brick-making materials?

- Brick making machine using sand, industrial waste, slag, slag can be the raw material for the road tiles, add a small amount of cement, through the road along the stone machine to suppress the molding,

- Q: Maintenance method of fly ash brick machine

- due to the harsh environmental conditions of the site restrictions, technical maintenance is not in accordance with the provisions of the maintenance "amount", but what care and what care to see what maintenance.

- Q: Automatic concrete brick machine bearing how to choose?

- When the fully automatic concrete brick making machine is running, it should always check whether the bearing seal of the equipment is. The grease in the bearing seat should be filled once every month. Every three months should be cleaned and replaced with oil frying. Normal after feeding, feeding together to be uniform, should be avoided mixed with iron hard objects;

- Q: Where is the brick of the tiles used to make the brick better?

- the surface was slightly bump, to prevent road reflection, to absorb the noise generated when driving the vehicle, can improve the vehicle traffic comfort and safety.

- Q: Installation and commissioning of hydraulic press

- 4, in addition to the hydraulic brick machine to carry out a comprehensive paint on the work, before the test machine but also on the movement of the parts of the relative sliding parts of the required lubrication.

- Q: What is the difference between a vacuum brick machine and an ordinary brick machine?

- While the ordinary brick machine did not take the vacuum equipment, so the hard side is definitely harder than ordinary brick machine.

- Q: Free burning brick brick brick machine can be how to classify

- According to aggregate: divided into ordinary concrete small hollow block, light aggregate small hollow block

Send your message to us

Roller crusher of brick making production line with best quality and excellent price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches