Concrete Block Making Machine CT3-20

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: Concrete Block Making Machine CT3-20

Ⅰ.Specifications of Concrete Block Making Machine CT3-20

1.automatic block making machine

2.ISO9001,CE

3.PLC-Siemens

4.Various high density bricks

5.Patented product

Ⅱ. Features of Concrete Block Making Machine CT3-20

- powered by petrol, diesel or electric motors.

- controls can be manual, semi-automatic or fully automatic.

- uses vibration and hydraulics to form blocks or bricks.

- change mould are available and it can shape different blocks and bricks.

- typically made from hardened steel or cast to withstand the strain of construction sites.

- These machines are manufactured and install to provide a user friendly design to be used by unskilled worker. They are also efficient and can therefore be used by small and medium enterprises as well as larger operations.

- The multi-functional machines can produce all kinds of products from the wall materials of new-style into products used in manicipality, garden, road paving, water conservancy, airport and wharf etc.

Ⅲ. Technical specification:

|

Overall Dimension |

5300x2450x2850mm |

|

Pallet Size |

1350x900x40mm (Bamboo)/ 1350x900 x30mm (Steel) |

|

Machine Weight |

15500KG |

|

Vibration Method |

Table Mould Resonate |

|

Vibration Frequency |

50-70Hz |

|

Circle Time |

15~25s |

|

Installed Capacity |

38kw |

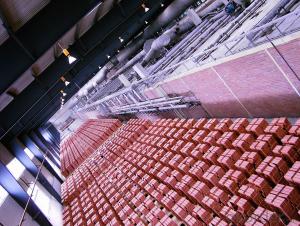

Ⅳ. Production capacity:

|

Specification of Products(mm) |

number of blocks per pallet |

pieces/hour |

pieces/300days(two shifts) | |

|

Block |

400*200*200 |

12 |

2880 |

13824000 |

|

390*190*190 | ||||

|

Hollow Block |

240*115*90 |

30 |

7200 |

34560000 |

|

Paving Block |

225*112.5*60 |

30 |

7200 |

34560000 |

|

Standard Block |

240*115*53 |

60 |

14400 |

69120000 |

Ⅴ. Advantages and benefits of having a Concrete Block Making Machine:

- you cut out the middle man in the production of bricks and blocks.

- customize the machine you buy to suit your operation perfectly.

- save time and money on transportation cost by producing blocks and bricks on site.

- choose between different moulds to fit the project specifications.

- be guarantee the quality of bricks and blocks you produce instead of depending on another company’s workmanship.

- flexible production schedules can ensure optimization of resources and man-power.

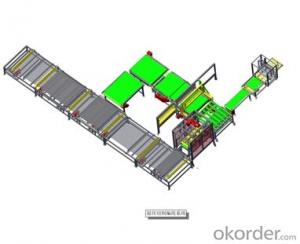

Invest scale you can made:

We got from simple line to fully automatic production line. Our experts can give good advice for each customer according to your needs for saving investment.

- Q: Fly ash Mianshao brick machine is not a kind of construction waste with coal ash to do brick, who understand this thing?

- As a result of automatic hydraulic molding machine with a high degree of automation, suppression of large, good quality products, high yield characteristics, has long been a brick-free production line of the preferred equipment. This Mianshaozhuanji has a wide range of materials applicable to the ability to use a variety of materials to prepare Mianshaozhuan; this equipment has a compact structure, large pressing, rigid, fully sealed dust, circulation lubrication, simple operation, high yield, D

- Q: What are the brick-making materials?

- This is to see what kind of brick machine, such as Mianshaozhuanji raw materials can be fly ash. Stone powder. Sand. Slag. Slag. Water slag. Ceramics. Construction waste, etc. to be a detailed understanding

- Q: Maintenance method of fly ash brick machine

- the quality of personnel to participate in maintenance is low, can not follow the maintenance of the operating procedures, there is no corresponding maintenance records.

- Q: The development of brick machine

- 1, ingredients machine. Using computer control, according to the selection of different raw materials, enter a recipe menu for automatic measurement, and then transfer the material into the mixer;

- Q: Automatic concrete brick machine bearing how to choose?

- After repair or adjustment of the discharge port, you should first use manpower to change the rotor, recognize the rotor and other parts do not conflict and stuck appearance and can be sensitive to change

- Q: Installation and commissioning of hydraulic press

- 3, check the working parts of the cylinder and the lubrication point is required to refuel, oil is appropriate.

- Q: What is the difference between a vacuum brick machine and an ordinary brick machine?

- Generally speaking, ordinary brick machine can only produce standard brick, and vacuum brick machine can not only produce standard brick, but also the production of porous hollow brick.

- Q: Hollow block brick brick machinery in use should pay attention to what the problem to ensure the normal operation of the brick machine?

- Fourth: the daily clean up the mold, the use of air compressor, soft tools to remove concrete residue, is strictly prohibited grappling, pry scraping mold;

- Q: What is the principle of vacuum brick machine

- Vacuum brick machine for coal gangue, shale, fly ash and clay and other raw materials to produce all kinds of hollow brick. The machine is equipped with wear-resistant metal powder spray coating technology; superior mixing shaft, mud knife shaft and body up and down body, etc., are aging, quenching and tempering, quenching; reducer gear are hard tooth; Pressure patented technology, a substantial increase in equipment life.

- Q: Free burning brick brick brick machine can be how to classify

- According to aggregate: divided into ordinary concrete small hollow block, light aggregate small hollow block

Send your message to us

Concrete Block Making Machine CT3-20

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords