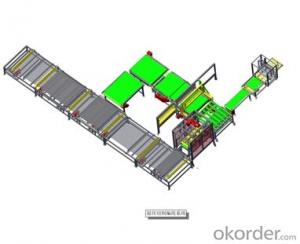

Mixer of brick making production line with high quality and excellent price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

SJJ Mixer is mainly used for continuously mixing, transporting and extruding crushed materials and it can also adjust moisture of materials, especially for the following materials: gangue, shale, clay and fly ash and etc.

Technical parameters:

| Type | Production capacity (m3/h) | Installed capacity (kw) | Rotation speed of shaft (rpm) | Weight (kg) | Dimension (m) |

| SJJ300-40J | 25-40 | 37 | 37 | 4373 | 5.9x1.8x1.0 |

| SJ300-50J | 45-50 | 45 | 37 | 4934 | 6.1x1.8x1.0 |

| SJ300-55 | 75 | 75 | 37 | 6800 | 6.4x1.8x1.1 |

| SJJ300-50 | 50-60 | 110 | 37 | 9860 | 7.4x1.8x1.3 |

| SJJ300-40 | 25-40 | 75 | 24 | 8850 | 6.4x1.8x1.3 |

- Q: Fly ash Mianshao brick machine is not a kind of construction waste with coal ash to do brick, who understand this thing?

- Mainly used to suppress the fly ash, sand, sand, sand, slag, slag as the main raw material of Mianshaozhuan, steamed sand bricks, refractory bricks and hollow brick production, is the country strongly advocated environmentally friendly Building materials equipment.

- Q: Burning brick and autoclaved lime sand brick what different

- Autoclaved brick through the mixing, digestion, through the autoclave brick machine into the kettle high temperature autoclaved to form autoclaved brick. (Also known as steamed brick).

- Q: Brief introduction of cement brick machine

- This equipment is known as Mianshaozhuanji, that is to say the production of cement brick or hollow block, do not need sintering, through a short period of time can be shipped to the factory.

- Q: Brief introduction of the brick machine

- The hoist is located at the top of the pallet box and the raw material hydraulic conveyor, and is mounted on the column of the mainframe frame. The mold head and the fuel tank are connected by four tubing, and the mold sleeve is installed on the main frame elastic support device.

- Q: Maintenance method of fly ash brick machine

- in the case of relatively scarce funds, can not be maintained on time, or the use of substandard oil and spare parts.

- Q: The development of brick machine

- A new year of China's brick industry can be described as "the fire can be a prairie fire," brick machine equipment can effectively use fly ash, slag, and even industrial waste, to recycle for the country, for the people continue to make contribution

- Q: Where is the brick of the tiles used to make the brick better?

- can absorb moisture and heat, adjust the surface of the local space temperature and humidity, the regulation of urban microclimate, ease the effect of urban heat island has a greater role 3, can reduce the city drainage and flood control pressure, to prevent public waters pollution and sewage treatment

- Q: What is the difference between a vacuum brick machine and an ordinary brick machine?

- In the water, because the vacuum brick machine is the first vacuum and water re-sintering, natural than ordinary brick coal time is short, forming fast.

- Q: Hollow block brick brick machinery in use should pay attention to what the problem to ensure the normal operation of the brick machine?

- Second: the use of often check the mold size, welding joint parts of the situation, there weld cracks, should be promptly repaired, there is excessive wear to adjust the aggregate size, wear and tear over the impact of product quality need to reprovision a new model;

- Q: Free burning brick brick brick machine can be how to classify

- According to aggregate: divided into ordinary concrete small hollow block, light aggregate small hollow block

Send your message to us

Mixer of brick making production line with high quality and excellent price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches