Plate feeder with best quality and excellent price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

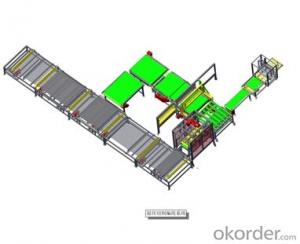

Plate feeder is mainly used to supply material for the next procedure. It is an ideal equipment for controlling the feeding speed and amount of raw materials.

| Type | Production capacity m3/h | Installed capacity (kw) | Width of belt (mm) | Weight (kg) | Dimension (m) |

| BL60 | 35 | 7.5 | 600 | 4749 | 5.6x1.9x1.4 |

| BL80 | 50 | 7.5 | 800 | 5029 | 5.6x2.1x1.4 |

| BL100 | 60 | 7.5 | 1000 | 5389 | 5.6x2.3x1.4 |

| BL120 | 85 | 7.5 | 1200 | 5979 | 5.6x2.5x1.4 |

- Q: Fly ash Mianshao brick machine is not a kind of construction waste with coal ash to do brick, who understand this thing?

- No burning brick without sintering, natural conservation, room temperature steaming can be. The equipment produced by the finished product burning brick to meet the building materials industry brick standard, is the comprehensive utilization of waste residue, eliminate environmental pollution, save land resources, promote urban and rural labor employment, fortune ideal equipment. The main equipment is Mianshaozhuanji, which is commonly known as the brick machine or brick machine, is the production of Mian Shaozhuan the main equipment, mainly divided into turntable, vacuum extruder and automatic hydraulic molding machine.

- Q: Burning brick and autoclaved lime sand brick what different

- Autoclaved lime sand brick (standard brick) is made of fly ash or other slag or lime as raw material, adding lime, gypsum and aggregate, prepared by embryo material, pressed molding, high efficiency steam curing and other processes.

- Q: Brief introduction of cement brick machine

- Cement brick machine is the use of slag, slag, fly ash, stone powder, sand, stones, cement and other raw materials, scientific ratio, water mixing, through the brick mechanical pressure to produce cement brick, hollow block or color road brick

- Q: Brief introduction of the brick machine

- A multi-purpose machine, no pallets, a stacking. The utility model products can produce a variety of tiles within a meter, hexagonal brick, lawn brick, slope protection brick, Curb, from raw materials to finished products are fully automatic, simple operation.

- Q: Cement brick machine brick machine advantages

- Cement hollow brick machine using the most advanced technology, transmission power, smooth operation, in place accurate, low maintenance rate advantages.

- Q: Maintenance method of fly ash brick machine

- the existence of "repair repair" thinking. There is no technical maintenance plan, the machine often with "disease" homework, only when the machine can no longer work, only sent to repair.

- Q: Where is the brick of the tiles used to make the brick better?

- Its role: 1, with good water permeability, breathability, can quickly penetrate the rain, add soil water and groundwater, to maintain soil moisture, improve the urban ground plants and soil microbial living conditions.

- Q: What is the principle of vacuum brick machine

- At the same time, the aircraft design is reasonable, compact structure, without the need to install the anchor bolts can be smooth operation, can greatly reduce the equipment running process due to jitter consumption power. The use of the equipment technology, variable waste into treasure energy saving, with significant economic and social benefits.

- Q: Brick machine operating procedures

- Check the electrical part of the fault and leakage phenomenon. Check if the packing concentration is appropriate. Check the triangle belt tightness is appropriate. After the motor is fed to the upper part of the cylinder, open the material gate, so that the material flow to the feeding body cylinder, at this time presses began to work.

- Q: Free burning brick brick brick machine can be how to classify

- According to the use of functions: divided into ordinary blocks, decorative blocks, insulation blocks, sound-absorbing blocks and other types.

Send your message to us

Plate feeder with best quality and excellent price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches