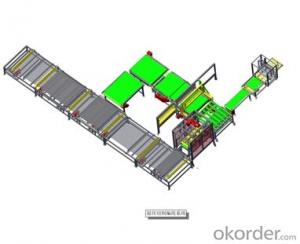

Clay Brick Making Machine JCJ45/45

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 Sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: Clay Brick Making Machine JCJ45/45

Ⅰ. Specifications of Clay Brick Making Machine JCJ45/45

|

No. |

Daily capacity |

50,000-100,000 pcs /day |

|

1 |

Land(㎡) |

4,000-10,000 |

|

2 |

Workshop(㎡) |

800~1,000 |

|

3 |

Total Power |

400kw 380V 50HZ |

|

4 |

Fuel |

Coal |

|

5 |

Finished brick size |

240*115*53mm (China Standard) |

|

6 |

Bricks drying way |

By dryer chamber |

|

7 |

Normal dryer |

8-16 chamber |

|

8 |

Production days in a year |

300 days |

|

9 |

Kiln type |

22-38 Chambers of Hoffman kiln |

|

10 |

Construction period |

3~5months |

|

11 |

Labors for operating the plant |

20~50 |

|

12 |

Working system |

10 hours for brick shaping,24 hours for kiln and dryer |

Ⅱ. Product description of Clay Brick Making Machine JCJ45/45

Production capacity: 8,000 to 11,000 pieces brick per hour

Suitable for production all kinds of cell brick with material like gangue, shale, pulverized coal ash as well as clay.

The spiral cut reamer of the machine adopts wear-resistance metal spray painting technology

The upper stage mixing shaft, the cut reamer big shaft, the up-down body are all processed by aging, quenching and tempering.

The reducer gear wheel is the hardened tooth face. Reasonable design and compact structure to make the equipment work steadily without installation of foundation bolts. Able to reduce the consumption of power for vibration in working process.

Basic Information:

Ⅲ. Advantages of Clay Brick Making Machine JCJ45/45 :

1.The Clay brick making machine with the Wear resistant metal spraying technology was applied to the screw, pug mill, axis of screw and seasoning, conditioning, quenching treatment make sure the body of brick extruder work in long life.

2. Clay brick making machine harden surface gear was adopted in reducer, clutch are a component with own patent, all the treatments make the brick machine life-saving

3.the reasonable design, compact structure reduce the energy consumption, without any shaking during working, even the Clay brick making machine can working normal without foundation bolts.

Ⅳ. Our service for Clay Brick Making Machine JCJ45/45

l Before-sales services:

(1) tell customer how to build a brick plant, the complete plant including three parts, brick shaping machinery, drying and firing.(Confirm clay, power electricity, water, land area, fund)

(2) Guide customers to choose the best and economic plant, recover the investment within short time.

(3) Site inspection

(4) We are responsible for the offer, flow chart, and detail specification of each machinery.

2 In-Sales services:

(1)Quality control must be inspected strictly

(2)In accordance with the agreements stipulated in the contract

3 After-sales services:

(1) We will send the technicians to guide with device installation, debugging and training operators until customers are fully satisfied.

(2) Guarantee for machinery, materials and equipment supplied under this quotation are valid for a period of 12 months after commissioning or 16 months after delivery whichever is earlier.

(3) Regular visit customer, consult with the customer feedback, come true with the customer's two-way communication

- Q: Fly ash Mianshao brick machine is not a kind of construction waste with coal ash to do brick, who understand this thing?

- Mainly used to suppress the fly ash, sand, sand, sand, slag, slag as the main raw material of Mianshaozhuan, steamed sand bricks, refractory bricks and hollow brick production, is the country strongly advocated environmentally friendly Building materials equipment.

- Q: What kind of configuration does the small semi-automatic cement brick machine include?

- Dosing Machine 2, Cement Warehouse 3, Cement Metering 4, Screw Conveyor 5, Base Material Mixer 6, Pigment Mixer 7, Bottom Belt Conveyor 8, Pigment Belt Conveyor 9, Elevated Horizontal Belt Conveyor 10

- Q: Brief introduction of cement brick machine

- Can be said to invest less, quick, is a lot of investors to invest in the popular industry.

- Q: The development of brick machine

- 1, ingredients machine. Using computer control, according to the selection of different raw materials, enter a recipe menu for automatic measurement, and then transfer the material into the mixer;

- Q: Automatic concrete brick machine bearing how to choose?

- After repair or adjustment of the discharge port, you should first use manpower to change the rotor, recognize the rotor and other parts do not conflict and stuck appearance and can be sensitive to change

- Q: Where is the brick of the tiles used to make the brick better?

- Its role: 1, with good water permeability, breathability, can quickly penetrate the rain, add soil water and groundwater, to maintain soil moisture, improve the urban ground plants and soil microbial living conditions.

- Q: What is the principle of vacuum brick machine

- static seal in the vacuum brick seal is relatively simple and easy to guarantee. If the sealing surface is not properly sealed, it is easy to cause the vacuum box to leak, so that the vacuum brick machine vacuum reduced, affecting its performance and product quality.

- Q: How does the economical brick machine use the building waste brick?

- The waste of construction waste will be processed into a raw material of building materials, that is, recycled aggregate,

- Q: Cement brick machine related issues

- This series of Mianshaozhuanji, the use of sand, slag, tailings, fly ash, coal gangue as the main raw material, the production of standard building used as a brick, you can also suppress thick brick, refractory brick, the use of the equipment variable waste Treasure, protect the environment, protect the cultivated land, the benefit of future generations, the use of equipment will bring you considerable economic benefits. There is also a block brick machine, which is mainly vibration forming, has been eliminated, and now was static pressure hydraulic brick machine replacement, static pressure brick investment cost is relatively large, but what shape for grinding The brick can be done, it is characterized by: Main features:

- Q: Free burning brick brick brick machine can be how to classify

- According to the empty form: divided into square hole block and round hole block.

Send your message to us

Clay Brick Making Machine JCJ45/45

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 Sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords