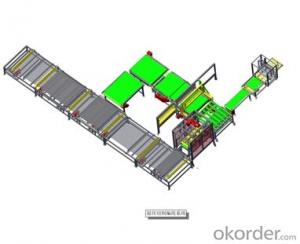

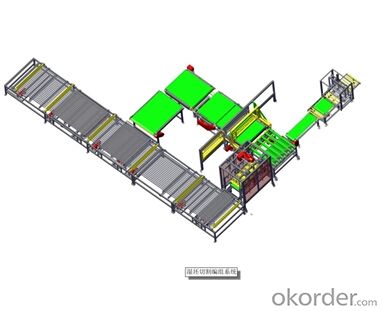

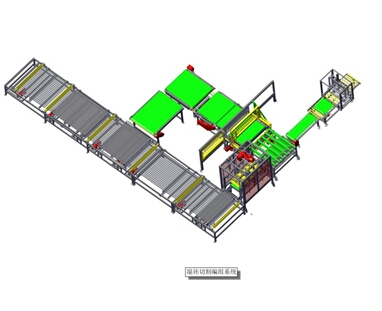

excellent wet brick cutting system with best price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

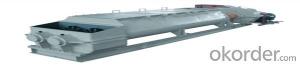

In this system, it is including of automatic wet brick cutting machine, speed-up belt, direction-change and speed-up belt, block cutting machine, direction-change belt, turning belt, converyor, automatic cutting machine.The working process is automatically controlled by PLC.

| Type | Production capacity (brick/hour) | Brick number/cutting | Installed capacity | Weight(kg) | Dimension(m) |

| ZQPSB32B | 28000 | 32 | 9 | 2257 | 6.0X3.0X1.9 |

| ZQPDB16 | 20000 | 16 | 11+1.5 | 2180 | 6.0X2.6X2.0 |

| ZQPG24 | 26000 | 24 | 4.75 | 1500 | 4.8X1.8X1.7 |

| ZQPG32 | 35000 | 36 | 6.25 | 1850 | 5.9X2.2X1.7 |

- Q: Burning brick and autoclaved lime sand brick what different

- Autoclaved lime sand brick (standard brick) is made of fly ash or other slag or lime as raw material, adding lime, gypsum and aggregate, prepared by embryo material, pressed molding, high efficiency steam curing and other processes.

- Q: Brief introduction of cement brick machine

- This equipment is known as Mianshaozhuanji, that is to say the production of cement brick or hollow block, do not need sintering, through a short period of time can be shipped to the factory.

- Q: Brief introduction of the brick machine

- The purpose of the utility model is to overcome the above shortcomings and provide an integrated hydraulic brick making machine which solves the problems of the existing brick making machine when the noise is large, the power consumption is high, the auxiliary tools are needed and so on.

- Q: Cement brick machine brick machine advantages

- Cement hollow brick machine with the current characteristics of similar domestic and foreign markets and the need to design and manufacture of new brick equipment.

- Q: What are the brick-making materials?

- This is to see what kind of brick machine, such as Mianshaozhuanji raw materials can be fly ash. Stone powder. Sand. Slag. Slag. Water slag. Ceramics. Construction waste, etc. to be a detailed understanding

- Q: Where is the brick of the tiles used to make the brick better?

- after the rain is not water, the snow does not slip, to facilitate the public safe travel.

- Q: Installation and commissioning of hydraulic press

- 4, in addition to the hydraulic brick machine to carry out a comprehensive paint on the work, before the test machine but also on the movement of the parts of the relative sliding parts of the required lubrication.

- Q: How does the economical brick machine use the building waste brick?

- and then through the construction waste brick machine further processing into a building products. Therefore, the reuse of construction waste needs to be divided into two parts,

- Q: Cement brick machine related issues

- Main features: the rotation part of all sealed, the pressure of oil, circulation lubrication, without artificial oiling, so that part of the full lubrication of the rotation to reduce wear and tear, the main part of the selection of high-quality steel, fine processing, to meet the maximum working pressure of more than two times Strength, increase the quality of the triangular pulley, increase the rotational inertia, increase the crankshaft gear diameter, so that the rotation force greatly increased, so the use of the machine pressure, fuel consumption, high yield.

- Q: Free burning brick brick brick machine can be how to classify

- According to aggregate: divided into ordinary concrete small hollow block, light aggregate small hollow block

Send your message to us

excellent wet brick cutting system with best price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords