AA1xxx Mill-Finished Aluminum Strips Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

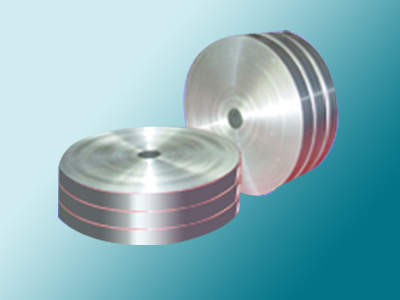

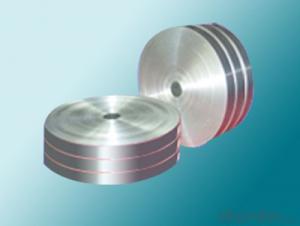

1.Structure of AA1xxx Mill-Finished Aluminum Strips Used for Construction Description

AA1xxx Mill-Finished Aluminum Strips Used for Construction has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

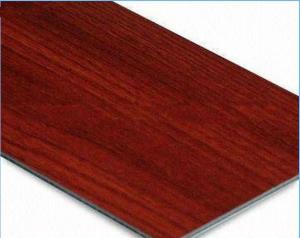

AA1xxx Mill-Finished Aluminum Strips Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA1xxx Mill-Finished Aluminum Strips Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.AA1xxx Mill-Finished Aluminum Strips Used for Construction Images

4.AA1xxx Mill-Finished Aluminum Strips Used for Construction Specification

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc. |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA1xxx Mill-Finished Aluminum Strips Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA1xxx Mill-Finished Aluminum Strips Used for Construction.

B.When will you deliver the products?

AA1xxx Mill-Finished Aluminum Strips Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: I have thousands of pounds of aluminum slab scrap where the acquisition, how much money a kilogram

- 5 to 6 dollars a pound.

- Q: Room decoration, aluminum-plastic plate and color plate where the difference, which is cheap?

- Aluminum-plastic panels are generally only suitable for exterior decoration and wall decoration, color steel plate with sandwich, one is the foam of the mezzanine, a glass of rock wool, suitable for simple rooms, purification workshop, partition, etc., noise Hot, sealed effect is good, you do room decoration I suggest you use color plate, the price is of course high color plate.

- Q: What are the folds of aluminum

- Aluminum-plastic composite board slot can generally open V-groove, U-slot, etc., several typical slotted as shown in Figure 1. Aluminum-plastic composite panel plate in the cutting board to take into account the size of the fold , Generally add about 25mm on each side. Cut the composite board needs four sides of the planing slot, that is cut to a certain width of the inner layer of aluminum and plastic layer, slot depth must be strictly controlled in the front aluminum plate at least 0.3mm thick plastic core To ensure that the aluminum-plastic composite panels have sufficient toughness to prevent the fold at the aluminum skin fracture, and then folded into a 90 ° angle, so the board surface weight and curtain wall at any time will be positive and negative wind load pressure by the four sides 0.5mm aluminum plate to bear, therefore, slotting is the aluminum-plastic composite panel panel of the weakest link, but also under the wind load under the first destruction of the site

- Q: Aluminum aluminum plate thickness how to detect

- Sent a qualified quality inspection unit testing.

- Q: What are you doing? Why is it so familiar with the knowledge of aluminum-plastic panels? Do you think there is now a market for getting aluminum-plastic composite panels? Thank you!

- We have been engaged in the production and sale of aluminum-plastic plates for 12 years.

- Q: Will the aluminum veneer replace the aluminum plate?

- Have their own advantages and disadvantages, will not replace. Upstairs to answer detailed, you can see

- Q: What is the specifications of the aluminum plate

- Other sizes can be negotiated with the manufacturer on request

- Q: 2000 watts of laser can cut 2.5mm aluminum-plastic plate (double-sided aluminum), cutting will be reflective of laser damage

- Can not, below a layer of plastic, do not wear

- Q: Heroes are good, I would like to know that aluminum-plastic plate is one side of the aluminum, one side of the kind of material is plastic? About three or four millimeters thick! Is it done with this board?

- Aluminum-plastic plate is an aluminum-plastic composite board. Is a layer of plastic (polyethylene or polyvinyl chloride) and two layers of aluminum composite made of aluminum skin appearance of fluorocarbon coating, the general thickness of 3-4 mm

- Q: The minimum thickness of single-layer aluminum and aluminum-plastic composite panels for curtain walls

- C. Indoor use of aluminum-plastic plate, the aluminum plate is generally used for the thickness of 0.20mm, the minimum thickness of not less than 0.10mm aluminum, the total thickness of the general 3mm. The coating is coated with polyester or acrylic.

Send your message to us

AA1xxx Mill-Finished Aluminum Strips Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords