Aluminum Sheets in Kennewick Wa - AA1100 3003 Aluminum Embossed Sheet Stucco

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

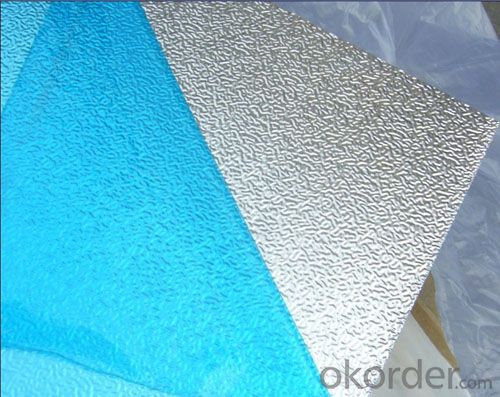

1. Description of AA1100 3003 Aluminum Embossed Sheet Stucco

The embossed oxidized panel is beautiful, with thickness from 0.25mm to 2.0mm, while the maximum width is 1250mm, after pattern embossed, the thickness could be 0.25 to 2.0mm. Additionally, we offer processing service for anodizing aluminum sheet, which could further strength sheet’s ability of anti-corrosion.

Pattern: Rhombic veins, orange peel veins, diamond veins, five-rib veins etc.

2. Specifications of AA1100 3003 Aluminum Embossed Sheet Stucco

Alloy | Temper | Specification(mm) | ||||

Thickness | Width | Length | Embossing Depth | Surface Treatment | ||

1050, 1060, 1100, 1070, 3003, 3105, etc. | O, H12, H14, H16, H18, H22, H24, H26, H32, etc. | 0.25~2.0 | ≤1250 | As per customer’s | 0.08~0.25 | Mill Finish, Bright Finish, Anodized, Color Coated |

Tolerance | ||||||

Thickness (base materials) | Thickness | Embossing Depth | Width | Length | Diagonal | |

0.25~0.5 | 0~0.05 | +/- 0.01 | +/-0.5 | +/- 1.0 | +/- 1.5 | |

> 0.5~2.0 | 0~0.10 | +/- 0.02 | +/-1.0 | +/- 1.5 | +/- 2 | |

We can produce as per customers’special requirements | ||||||

3. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

4. Image of AA1100 3003 Aluminum Embossed Sheet Stucco

5. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

- Q: Are aluminum sheets suitable for interior design applications?

- Aluminum sheets are an excellent choice for interior design purposes. This material is both versatile and durable, allowing for various creative uses in enhancing the aesthetics of indoor spaces. Its malleability enables easy shaping, cutting, and manipulation, resulting in unique and contemporary designs. Different finishes, such as brushed, polished, or textured, further expand the design options. One major advantage of utilizing aluminum sheets in interior design is their lightweight composition. This feature simplifies handling and installation, reducing labor and transportation expenses. Additionally, aluminum's corrosion resistance makes it perfect for environments with high humidity or moisture, such as bathrooms or kitchens. Aluminum sheets find application in various aspects of interior design, including wall cladding, ceiling panels, room dividers, furniture, and decorative elements. The ability to paint or coat them in different colors allows seamless integration into any design scheme. Furthermore, perforation or engraving can create patterns or intricate designs, adding a distinct visual appeal to the space. Moreover, aluminum is a sustainable material with high recyclability. The recycling process consumes significantly less energy compared to the production of new aluminum, making it an environmentally friendly option for interior design applications. To summarize, the versatility, durability, lightweight nature, corrosion resistance, and manipulability of aluminum sheets make them highly suitable for interior design. They offer numerous design possibilities and can be used in various applications, rendering them a popular choice among designers and architects.

- Q: Can aluminum sheet be used for insulation?

- Although aluminum sheet can be utilized for insulation purposes, it is not as efficient as alternative insulation materials like fiberglass or foam. This is due to its low thermal conductivity, which implies that it is not a proficient heat conductor. Nevertheless, aluminum lacks adequate insulating properties on its own since it does not offer substantial resistance to heat flow. To enhance its effectiveness for insulation, aluminum sheet is frequently combined with other insulating materials. For instance, aluminum foil is commonly employed as a radiant barrier in buildings to reflect heat and diminish the amount of heat transferred through walls and roofs. In summary, while aluminum sheet can contribute to insulation, it is typically employed in conjunction with other materials to provide superior thermal insulation.

- Q: How do aluminum sheets perform in terms of dimensional stability?

- Aluminum sheets generally exhibit good dimensional stability due to their low coefficient of thermal expansion, meaning they are less likely to warp or deform when exposed to temperature changes compared to other materials.

- Q: What is the composition of 101 aluminum sheets?

- The composition of 101 aluminum sheets typically refers to the alloy used in their manufacturing. Aluminum alloy 101 is a commercially pure aluminum with a minimum of 99.0% aluminum content. It does not contain any significant amounts of other elements, making it the most basic and pure form of aluminum available. This high purity level makes it highly resistant to corrosion and provides excellent electrical conductivity. 101 aluminum sheets are often used in applications where a high degree of electrical conductivity or corrosion resistance is required, such as in electrical wiring, heat exchangers, and chemical processing equipment.

- Q: Are aluminum sheets suitable for roofing?

- Indeed, aluminum sheets prove to be a fitting choice for roofing purposes. Renowned for its lightweight nature, durability, and corrosion resistance, aluminum stands out as a favored material in the roofing industry. Moreover, its non-combustible properties render it a safer alternative. The ease of installation and maintenance further add to its appeal, as do its ability to withstand adverse weather conditions like heavy rain, snow, and wind. Notably, aluminum also earns accolades as an environmentally conscious option, boasting 100% recyclability. In summary, aluminum sheets offer a trustworthy and enduring roofing solution for both residential and commercial edifices.

- Q: Can aluminum sheets be used for insulation jackets?

- Indeed, insulation jackets can indeed employ aluminum sheets. Aluminum possesses exceptional thermal conductivity characteristics, enabling it to proficiently deflect heat and hinder the transmission of thermal energy. Consequently, it becomes the perfect substance for insulation jackets, as it aids in preserving temperature regulation and reducing heat loss or gain. Furthermore, aluminum sheets are lightweight, long-lasting, and impervious to corrosion, rendering them a pragmatic option for insulation applications.

- Q: I don't know if the electrons are being passed from my hand to the aluminum or from the aluminum to my hand.Thanks

- Aluminum is a metal and every metal has a property that it holds electrons of its outer most orbital quite loosely ( it is electropositive ). And our hand's skin consists of mostly COVALENT bonded compounds which hold their electrons quite tightly. So if we touch aluminum the chances are strong that the electrons are being transferred from aluminum to our hands. But since our hand have covalent compounds so the total transfer must be very small if it is anyway. Otherwise we feel shock every time we touch a neutral aluminum also IF U develop some negative charge then aluminum will take that charge since it has small hold on the outermost electrons. so it easily takes charge frm yr hand at lower potential to its ground potential surface.

- Q: How do aluminum sheets perform in terms of impact resistance?

- Aluminum sheets are known for their excellent impact resistance properties. Due to their high strength-to-weight ratio, they can withstand significant impacts without deforming or breaking easily. Additionally, aluminum has inherent toughness and flexibility, which allows it to absorb and distribute the force of an impact, minimizing the risk of damage. This makes aluminum sheets a preferred choice for applications requiring durability and resistance to impact, such as in the automotive, aerospace, and construction industries.

- Q: iron-based alloys over aluminum in structural members of bridges and buildings?

- Because it's lighter with about the same strength as iron alloys

- Q: Can aluminum sheets be painted or coated with different colors?

- Yes, aluminum sheets can be painted or coated with different colors. Aluminum is a versatile material that can be easily painted or coated to achieve various colors and finishes. The process typically involves pre-treating the surface, applying a primer, and then applying the desired paint or coating. This allows for customization and aesthetic enhancement of aluminum sheets in numerous applications.

Send your message to us

Aluminum Sheets in Kennewick Wa - AA1100 3003 Aluminum Embossed Sheet Stucco

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords