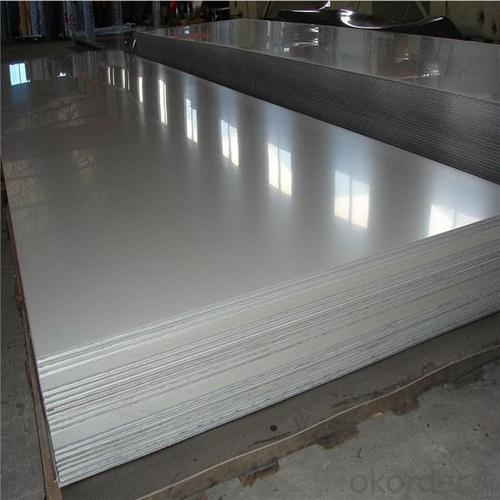

904l Stainless Steel Sheet mill edge and slit edge

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

904l Stainless Steel Sheet mill edge and slit edge

1. Material: 904L

2. Standard: ASTM, AISI,JIS, DIN,GB

3.Cold rolled stainless steel sheet

Thickness : 0.3mm-3.0mm

Width : 1000mm/1219mm/1500mm

Length : 2000mm/2438mm/4000mm/6000mm or cutting randomly

Model size : 0.3mm-3.0mm(TK)*1000mm(W)*2000mm(L)

0.3mm-3.0mm(TK)*1219mm(W)*2438mm(L)

0.3mm-3.0mm(TK)*1500mm(W)*4000mm(L)

Surface : 2B, BA, 8K, HL, 2D, Golden 8K, Black 8K etc.

4.904l Stainless Steel Sheet mill edge and slit edge

Thickness : 3.0mm-120mm

Width : 1219mm/1500mm/1800mm/2000mm

Length : 2000mm/2438mm/4000mm/6000mm or cutting randomly

Model size : 3.0mm-120mm(TK)*1219mm(W)*2438mm(L)

3.0mm-120mm(TK )*1500mm(W)*6000mm(L)

3.0mm-120mm(TK) *1800mm(W)*6000mm(L)

3.0mm-120mm(TK) *2000mm(W)*6000mm(L)

Surface : No.1

5.Characteristics and application904l Stainless Steel Sheet mill edge and slit edge

Surface finish | Characteristics and application |

NO.2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

NO.3 | Polished with abrasive belt of git#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria,but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators,door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror,kitchen apparatus,ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

5.Payment : Usually 30% of the amount by T/T as deposit , and the balance money shall be paid by T/T after got the faxed B/L.Or L/C at sight .

6. Package: Kraft paper+Hard board+metal/wooden pallet+metal strip; or based on the customer requirement.

7. USE: construction.machinebuilding,container manufacturing,shipbuilding,bridges and so on.

The operating philosophy of our company : high quality and best service and competitive price and prompt delivery .We sincerely welcome the old and new customers to inquiry the price . any questions and needs you have , pls don't hesitate to contact us anytime .

- Q: What is the coefficient of expansion of stainless steel sheets?

- The coefficient of expansion of stainless steel sheets can vary depending on the specific grade or alloy of stainless steel being used. However, in general, stainless steel has a coefficient of expansion ranging from 10.8 to 16.3 x 10^-6 per degree Celsius. This means that for every degree Celsius increase in temperature, stainless steel sheets will expand by approximately 10.8 to 16.3 millionths of their original length. It is important to note that different grades of stainless steel may have slightly different coefficients of expansion, so it is always recommended to consult the manufacturer or specific material specifications for accurate information.

- Q: What does "80 wire" stainless steel plate mean? How much more expensive than the average stainless steel plate?

- Stainless steel terminology, the general thickness of C to calculate the negative difference, the 1 C is 0.01MM, so 80C is 0.8MM. 0.8MM thick stainless steel with different thickness, different prices, generally about Yuegui thin.

- Q: Can stainless steel sheets be painted or coated?

- Yes, stainless steel sheets can be painted or coated. However, it is important to properly prepare the surface by cleaning and applying a suitable primer before painting or coating to ensure adhesion and durability of the finish.

- Q: Can stainless steel sheets be used for railway infrastructure?

- Railway infrastructure can utilize stainless steel sheets, as they offer numerous advantages. Stainless steel is a versatile and enduring material that is well-suited for railway applications. Its resistance to corrosion makes it suitable for outdoor and high humidity environments, which are commonplace in railway infrastructure. Stainless steel sheets can withstand severe weather conditions, such as extreme temperatures, rain, and UV radiation, without deteriorating or corroding. As a result, they are an excellent choice for railway tracks, bridges, tunnels, and other structures that are exposed to the elements. Moreover, stainless steel sheets possess an exceptional strength-to-weight ratio. This characteristic allows for the construction of lightweight yet robust railway infrastructure. Consequently, the overall structure's load is reduced, enabling easier transportation and installation. Stainless steel is also fire-resistant and can withstand significant impact, making it an ideal option for railway applications that prioritize safety. Furthermore, stainless steel sheets are effortless to clean and maintain, which is advantageous for railway infrastructure that necessitates regular upkeep. Their aesthetic appeal can be easily restored through polishing, ensuring a clean appearance. Additionally, stainless steel is recyclable, making it an environmentally friendly choice for sustainable railway construction. To summarize, due to their corrosion resistance, strength, durability, fire resistance, ease of maintenance, and sustainability, stainless steel sheets are indeed suitable for railway infrastructure.

- Q: Can stainless steel sheets be used for roofing?

- Yes, stainless steel sheets can be used for roofing. Stainless steel is a durable and long-lasting material that is resistant to corrosion, rust, and weathering, making it an excellent choice for roofing applications. It is commonly used in industrial, commercial, and residential roofing projects. Stainless steel sheets offer high strength and are able to withstand extreme weather conditions, including heavy rain, snow, and wind. Additionally, stainless steel is fire-resistant and does not warp or crack, providing a reliable and secure roofing solution. However, it is important to note that stainless steel roofing materials can be more expensive than other roofing options, so cost considerations should be taken into account.

- Q: What are the different types of stainless steel sheet grades available?

- There are several different types of stainless steel sheet grades available, including 304, 316, 430, and 201. Each grade has its own unique properties and applications, making them suitable for various industries and purposes.

- Q: Can stainless steel sheets be used for architectural wire mesh?

- Architectural wire mesh can indeed be made from stainless steel sheets. This material is highly versatile and widely used in architecture because of its durability, attractive appearance, and resistance to corrosion. By transforming stainless steel into sheets, it becomes easily manipulable and can be woven into wire mesh panels suitable for various architectural purposes, including building facades, interior partitions, sunscreens, and balustrades. The use of stainless steel sheets for architectural wire mesh allows for the creation of intricate and visually appealing designs, while also providing strength, stability, and longevity to the structure. Furthermore, customization options are available for stainless steel wire mesh, including mesh size, wire diameter, and finish, ensuring that it meets the specific requirements of each architectural project.

- Q: What are the different types of stainless steel sheet finishes for automotive applications?

- Some of the different types of stainless steel sheet finishes for automotive applications include brushed, polished, satin, mirror, and textured finishes. These finishes vary in terms of appearance, texture, and level of reflectivity, providing options for various aesthetic preferences and functional requirements in the automotive industry.

- Q: Can stainless steel sheets be used in the automotive industry?

- Yes, stainless steel sheets can be used in the automotive industry. Stainless steel is often used in the construction of automotive parts due to its exceptional strength, durability, and resistance to corrosion. It is commonly used in the production of components such as exhaust systems, fuel tanks, bumpers, and trim. Stainless steel sheets offer a high degree of flexibility in terms of design possibilities, allowing manufacturers to create complex shapes and structures. Additionally, stainless steel's aesthetic appeal and ease of maintenance make it a popular choice in the automotive industry.

- Q: What are the different types of patterned finishes available for stainless steel sheets?

- Stainless steel sheets come in a variety of patterned finishes, each offering a unique aesthetic and functionality. Some of the most commonly used finishes include: 1. Diamond: This finish has a raised diamond-shaped texture on the surface, providing better grip and slip resistance. It is often used for flooring or industrial equipment. 2. Linen: The linen finish resembles woven fabric, adding a subtle elegance to stainless steel sheets. It is commonly used in interior design applications like wall cladding or decorative panels. 3. Checkered: This finish creates a checkerboard-like appearance with a grid of raised squares or rectangles. It adds visual interest and can give a retro or industrial look to stainless steel sheets. 4. Bead Blasted: In this finish, fine glass beads are blasted onto the surface to create a matte texture with a slightly rough surface. It is often used in architectural applications to provide a modern and uniform appearance while reducing glare and fingerprints. 5. Etched: This finish involves chemically altering the surface to create intricate patterns or designs. It can range from simple line patterns to complex images and is commonly used for decorative purposes like signage, artwork, or custom designs. 6. Sandblasted: Similar to bead blasting, sandblasting uses high-pressure sand or other abrasive materials to create a textured surface. It provides a rougher and more pronounced pattern, making it suitable for industrial or rugged applications. 7. Mirror: Although not technically a patterned finish, the mirror finish is highly popular for stainless steel sheets. It is achieved through a series of polishing and buffing processes, resulting in a highly reflective surface similar to a mirror. It is commonly used in architectural elements like cladding or decorative accents. In conclusion, the choice of patterned finish for stainless steel sheets depends on the desired aesthetic, functionality, and specific application requirements. Each finish offers a distinct look and texture, providing endless possibilities in design.

Send your message to us

904l Stainless Steel Sheet mill edge and slit edge

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords