8xxx Series Mill Finished Stucco Embossed Aluminum Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Mill Finined Aluminum Sheets 8xxx Description

Mill Finined Aluminum Sheets 8xxx is cut from aluminum coils 8xxx.. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Mill Finined Aluminum Sheets 8xxx is clean, flat, no wrinkle, no scratch, oil free, widly used in construction /Furniture/decorate/industry,etc.

2.Main Features of Mill Finined Aluminum Sheets 8xxx

• excellent quality,good credit

• competitive price,comfortable service

• Goode mechanical property

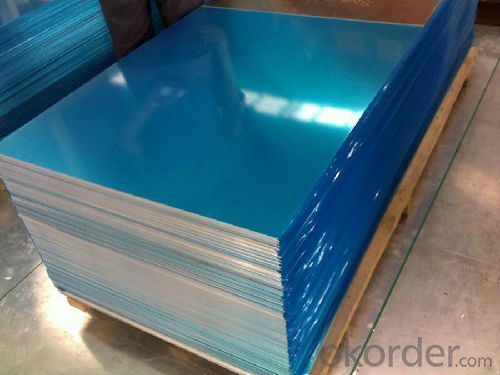

3.Mill Finined Aluminum Sheets 8xxx Images

4.Mill Finined Aluminum Sheets 8xxx Specification

Alloy | AA8xxx (AA8011 etc.) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,ASTM |

5. FAQ of Mill Finined Aluminum Sheets 8xxx

A.What is the MOQ?

The MOQ for each size is 8 tons, because it is D.C quality.

B. Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum sheets be used for air conditioning systems?

- Yes, aluminum sheets can be used for air conditioning systems. Aluminum is a popular material choice for air conditioning components due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion. It is commonly used for manufacturing air conditioner coils, fins, and heat exchangers.

- Q: What are the different types of surface treatments available for architectural aluminum sheets?

- There are several types of surface treatments available for architectural aluminum sheets, including anodizing, powder coating, and PVDF coating. Anodizing involves creating a protective oxide layer on the surface of the aluminum, providing enhanced corrosion resistance and durability. Powder coating involves applying a dry powder to the surface of the aluminum and then curing it with heat, resulting in a durable and decorative finish. PVDF coating, also known as Kynar coating, is a type of liquid coating that provides excellent weather resistance and color retention. These surface treatments can enhance the appearance and performance of architectural aluminum sheets for various applications.

- Q: What are aluminum sheets made of?

- Aluminum sheets are typically made of pure aluminum or aluminum alloy, which is a combination of aluminum and other elements such as copper, magnesium, or zinc. The exact composition of the alloy depends on the specific application and desired properties of the sheet. Pure aluminum sheets are softer and more malleable, while alloyed aluminum sheets offer increased strength, durability, and resistance to corrosion. The sheets are produced through a process called rolling, where a large block or ingot of aluminum is passed through a series of rollers to reduce its thickness and create the desired sheet size.

- Q: what's the size of gap while pressing 6mm aluminum sheet?

- unilaterial gap is 0.1-0.15mm, and you can change the gap according to cutting effect.

- Q: Can aluminum sheets be used for sound insulation?

- Yes, aluminum sheets can be used for sound insulation. Aluminum has good soundproofing properties due to its high density and ability to reflect sound waves. When used as a barrier or in combination with other sound-absorbing materials, aluminum sheets can effectively reduce noise transmission.

- Q: What is the weight of aluminum sheets per square foot?

- The weight of aluminum sheets per square foot varies depending on the thickness of the sheet. On average, aluminum sheets weigh around 0.96 pounds per square foot.

- Q: I was looking at Audioque subs earlier and what is the difference between copper and aluminum coiled subs. do aluminum last longer or something?

- to maintain it common......Copper is better at removing or soaking up warmth than aluminum yet aluminum is better at dissipating it or doing away with it. i think it is why you spot aluminum CPU coolers with copper cores.

- Q: How are aluminum sheets measured and specified?

- Aluminum sheets are typically measured and specified based on their thickness, width, and length. The thickness is commonly referred to as the gauge, and it is measured in inches or millimeters. The sheet's width and length are also specified in either inches or millimeters. To measure the thickness of an aluminum sheet, a gauge is used. The gauge is a standardized measurement tool that determines the sheet's thickness. The lower the gauge number, the thicker the sheet. For example, a 10-gauge aluminum sheet is thicker than a 16-gauge sheet. The width and length of an aluminum sheet are typically measured in inches or millimeters. The width refers to the horizontal measurement of the sheet, while the length refers to the vertical measurement. These dimensions are crucial in determining the sheet's size and suitability for specific applications. In addition to the gauge, width, and length, aluminum sheets may also be specified based on their alloy composition or temper. The alloy composition indicates the specific combination of metals present in the sheet, such as aluminum-magnesium, aluminum-zinc, or aluminum-copper alloys. The temper refers to the heat treatment process the sheet has undergone, which affects its mechanical properties, such as hardness and flexibility. Overall, aluminum sheets are measured and specified by their thickness (gauge), width, and length. These measurements, along with additional specifications like alloy composition and temper, help ensure the appropriate selection and use of aluminum sheets for various applications in industries such as construction, automotive, aerospace, and more.

- Q: I recently moved into a 1975 house with aluminum wiring. I will be going through and checking/replacing all receptacles and switches with CO/ALR rated ones as I don't have a budget right now to rewire the house. I am wondering if I should be checking all of the ceiling lights as well as some of them would be very difficult to access. Are lights as big a concern with aluminum connections as receptacles? I am sure some of the lights are newer and would have copper wire connected to the aluminum. Should I be concerned about the type of wire nuts used here?Anything else that I should be checking?

- Connections at ceiling lights have far less potential for a problem, but a potential none the less. So, while you are at it, go ahead and check them. The antioxidant compound and al/cu listed wire nuts (marriets) are the correct and proper materials to use. I applaud you for having done your homework. After tightening each connector be sure to pull on each and every wire to ensure they are good and tight. When combining solid and stranded wire, slide the stranded past the solid about an 1/8 before capping. We in the trade use 9 lineman's pliers to twist all wires before capping them. An inexpensive pair (of Lineman's) can be had for under $20. A good pair of wire strippers (with built in screw cutters) can be had for about $15. I mention the screw cutter because there is a good chance that somewhere along the line you will find a location where the stock 7/8-1 screw bottoms out against something before it gets tight. If you force it it will strip out. Not to mention it might dig into the insulation on a wire resulting in a short. Screws in devices (receptacles, switches, dimmers etc.) are 6-32 and light fixtures are typically 8-32. I would also get a non-contact tester. A.k.a. inductive tester. Very handy at times. When you are sure the power is off to a box it might not be. On an occasion another hot will be present. The beep testers will quickly alert you to the presence of another live circuit. A multi-tester will allow you to identify wires should you fail to mark them before working on them. If you mark the location of each wire to a 3 or 4-way switch before replacing it you will save yourself a lot of time. Same with wires to any GFI receptacles. Swapping wires location to location may not be correct. Some have the Line terminals on one side, while most have them on the top. But I get the impression you have a bit of experience or a friend who does helping you with this.

- Q: Is it possible to install aluminum sheets on an existing roof structure?

- <p>Yes, aluminum sheets can be installed on existing roofs. This process typically involves removing the old roofing material and ensuring the roof structure is sound. Aluminum sheets are lightweight, durable, and resistant to corrosion, making them a popular choice for roof installations. They can be installed over a solid substrate, such as plywood or metal decking, and often require a proper underlayment to ensure watertightness. It's important to follow manufacturer guidelines and local building codes when installing aluminum sheets on an existing roof. Professional installation is recommended to ensure the roof's integrity and longevity.</p>

Send your message to us

8xxx Series Mill Finished Stucco Embossed Aluminum Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords