60gsm Black Fiberglass Facing Tissue for Acoustic-60C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Fiberglass Tissue for Thermal Insulation

Fiberglass Tissue is a kind of facing, which is made of by the white fiberglass tissue, and special production process.

Good Aspect of Fiberglass Tissue for Thermal Insulation

Light weight

• Good visual effect

• High reflective insulation

Packing of Fiberglass Tissue for Thermal Insulation

1. Waterproof paper then PVC shrinking Film

2. Water-Proof film only

3. Heat resistant, water proof, stable at high temperature;

4.Environmentally friendly, no smell and not-toxic;

5.Smooth and clear surface;

Specification of Fiberglass Tissue for Thermal Insulation

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 105 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 60 | ASTM D828 |

Burst strength | N | 40 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

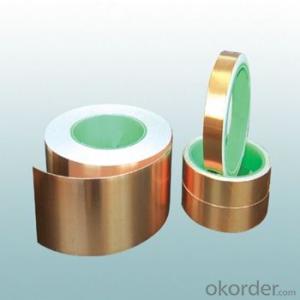

Pictures of Fiberglass Tissue for Thermal Insulation

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. What is the storage condition?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Describe the process of creating black fiberglass tissue, including the materials used and the steps involved.

- <p>The production process of black fiberglass tissue involves several key steps. First, raw materials such as glass fibers are combined with a black pigment or dye to color the fibers. These fibers are then melted and extruded into thin strands. The strands are gathered together and woven or laid into a sheet form to create the tissue. This sheet is then treated with a resin to bind the fibers together, resulting in a strong, black fiberglass tissue. The final product is often used in various industrial applications due to its strength and resistance to heat and chemicals.</p>

- Q: Is it possible to use black fiberglass tissue as an alternative to regular paper tissues?

- <p>Black fiberglass tissue is not a suitable substitute for paper tissues. Fiberglass is a type of glass wool that is used for insulation and other industrial applications. It is not designed for personal use, especially not in contact with the skin or for cleaning purposes. Using fiberglass tissue could cause skin irritation, respiratory issues, and other health problems. Paper tissues are specifically designed for personal use, providing a soft and safe material for everyday needs.</p>

- Q: What are the chemical characteristics of black fiberglass tissue?

- <p>Black fiberglass tissue, often referred to as black glass fiber cloth, is known for its high-temperature resistance, corrosion resistance, and electrical insulation properties. It is primarily composed of glass fibers that have been treated with a black resin to give it color and additional properties. The chemical properties include resistance to alkalis, acids, and many organic solvents. It does not conduct electricity and has low thermal conductivity, making it suitable for thermal insulation. The black fiberglass tissue is also non-flammable and has good mechanical strength, which makes it useful in various industrial applications where these properties are beneficial.</p>

- Q: This question asks for a comparison between black fiberglass tissue and other construction materials, focusing on their properties and applications.

- <p>Black fiberglass tissue, also known as black glass fiber tissue, is a type of composite material made from glass fibers and resin. Compared to other building materials, it offers several advantages. It is lightweight, which reduces the load on structures, and has high tensile strength, making it durable. It is also resistant to corrosion and has good thermal insulation properties. Unlike some materials, it doesn't conduct heat or electricity, which can be beneficial in certain applications. However, it is more expensive than traditional materials like wood or concrete and requires special handling due to the potential health risks associated with the fine fibers. It's commonly used in roofing, insulation, and other applications where its unique properties are beneficial.</p>

- Q: What is the lifespan of fiberglass facing?

- The lifespan of fiberglass facing can vary depending on a few factors such as the quality of the material, the environment it is exposed to, and how well it is maintained. However, on average, fiberglass facing can last anywhere from 20 to 30 years. With proper care and maintenance, it is possible for fiberglass facing to last even longer. Regular cleaning, avoiding harsh chemicals or abrasive cleaners, and protecting it from excessive sunlight and extreme temperatures can help prolong its lifespan.

- Q: This question asks about the impact of black fiberglass tissue on the quality of air inside residential homes.

- <p>The use of black fiberglass tissue in residential homes can affect indoor air quality in various ways. Black fiberglass is a type of insulation material that can help retain heat and reduce energy costs. However, if it contains certain chemicals or if it's improperly installed, it may release fibers or particles into the air, potentially causing respiratory issues or allergies. Additionally, if the fiberglass is not treated to resist moisture, it could lead to mold growth, further impacting air quality. It's important to ensure that any fiberglass insulation used in homes is of high quality, properly installed, and treated to prevent such issues. Regular maintenance and air quality checks can also help maintain a healthy indoor environment.</p>

- Q: China's glass fiber product code is what?

- Will be replaced by N or K, respectively, said ND-8, KH-550; ④ EM will be used instead of CM, said the alkali fiberglass

- Q: This question asks for the steps and considerations to properly install black fiberglass tissue to ensure its effectiveness and longevity.

- <p>To install black fiberglass tissue effectively and ensure its durability, follow these steps: 1) Clean the surface to be covered thoroughly to remove any dirt or debris. 2) Cut the fiberglass tissue to the required size, ensuring it fits snugly over the surface. 3) Apply a suitable adhesive, such as epoxy resin, to the surface and fiberglass tissue, following the manufacturer's instructions. 4) Press the fiberglass tissue firmly onto the surface, smoothing out any wrinkles or air bubbles. 5) Apply a protective layer of resin over the tissue to seal and protect it. 6) Allow the adhesive to cure fully as per the manufacturer's recommendations. 7) Regularly inspect and maintain the fiberglass tissue to prevent damage and prolong its lifespan.</p>

- Q: What is the tensile strength of black fiberglass paper, measured in terms of force per unit area?

- <p>The tensile strength of black fiberglass paper can vary depending on the specific type and manufacturer. Generally, it is known to have a tensile strength ranging from 100 to 200 MPa (megapascals). This high tensile strength makes it suitable for applications requiring durability and resistance to tearing, such as in electrical insulation and reinforcement in composite materials. It's important to check the specific product specifications for precise tensile strength values.</p>

- Q: What are the methods to avoid entanglement of glass fiber paper during its application?

- <p>To prevent glass fiber paper from getting tangled during use, ensure proper storage in a dry, cool place away from direct sunlight. Use gloves to handle the paper to avoid skin oils that can cause sticking. Apply a light coating of talcum powder or a similar anti-static agent to reduce static electricity, which often contributes to tangling. Cut the paper with sharp, clean tools to minimize fraying. When using, unroll or unfold the paper slowly and carefully to prevent it from bunching up. Regularly clean and maintain the machinery or equipment used with the glass fiber paper to prevent buildup that could cause entanglement.</p>

Send your message to us

60gsm Black Fiberglass Facing Tissue for Acoustic-60C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords